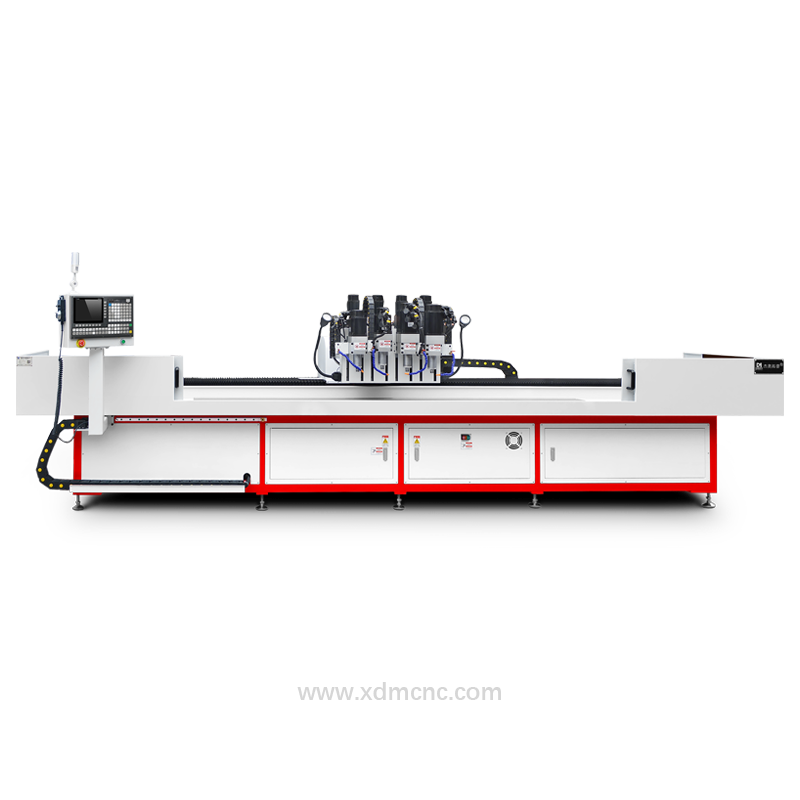

Why Choose DUOMI CNC Multi-Spindle Drilling Machines?

Simultaneous Multi-Spindle Processing

Instead of drilling holes one by one, DUOMI CNC's multi-spindle CNC drilling machine allows you to drill and countersink multiple holes at the same time, drastically reducing cycle time and increasing daily output. Whether you're working with aluminum, carbon steel, or alloy guide rails, synchronized spindles maintain uniformity and high surface finish.

High-Speed, High-Precision Countersinking

The multi-spindle CNC drilling machine is equipped with high-speed servo motors and precision ball screws to deliver consistent hole depth and angle. Our CNC software automatically calculates feed rates and spindle positioning, ensuring every countersink is perfect—ideal for applications requiring bolt or fastener flush fitting.

No Programming Experience Needed

With DUOMI's user-friendly interface, operators can set drilling positions via graphical input. For repeat jobs, you can save and recall processing programs in seconds, reducing downtime and labor training requirements.

Custom Spindle Layouts Available

Each DUOMI CNC multi-spindle CNC drilling machine can be customized with 2 to 12 spindles depending on your rail size and hole spacing requirements. Whether you process narrow elevator guide rails or wide industrial slideways, we configure the layout to fit your exact production needs.

Ideal for Rail Manufacturers and Automation Suppliers

This machine is specially designed for manufacturers producing linear motion guides, elevator rails, machine slideways, and heavy-duty automation tracks. Our customers report up to 70% reduction in processing time compared to single-spindle methods.

DUOMI CNC — Trusted by Global Manufacturers

With over a decade of CNC innovation, DUOMI CNC has become a preferred supplier for businesses across Asia, Europe, and North America. We focus on intelligent drilling solutions that help manufacturers lower costs, reduce errors, and scale operations.

Technical Highlights:

Spindle Count: 2–12 (customizable)

Max Rail Length: Up to 60000mm

Drilling Diameter: 2mm–20mm

Countersinking Angle: 90° / 120° (custom options)

Positioning Accuracy: ±0.01mm

Automatic Chip Removal and Lubrication System

Optional Robotic Arm Integration for Loading / Unloading

Get a Free Quote or Sample Test

Want to test your rail sample on our machine? DUOMI CNC offers free testing services and expert consultation. Contact us today to discuss your project needs and receive a tailored solution.