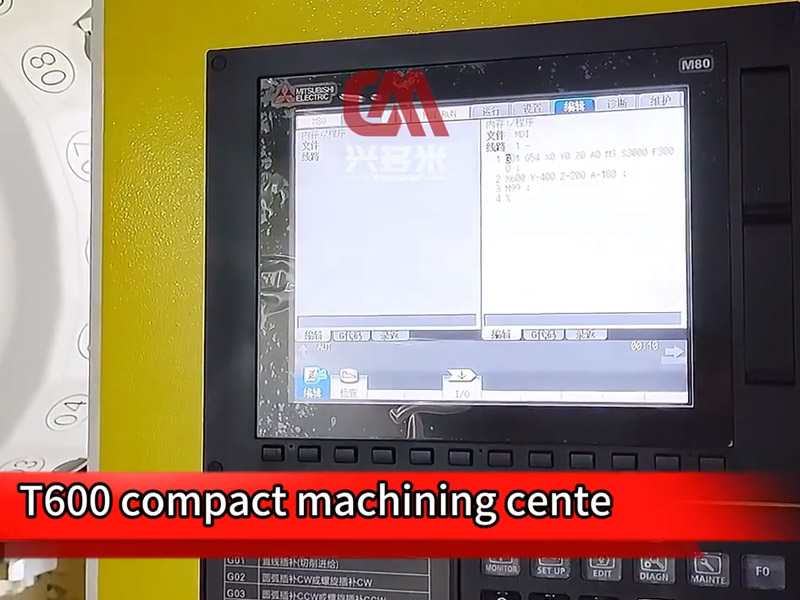

T Series 5-axis CNC machining center U200

CNC Drilling & Tapping Machine

Model: T-U200

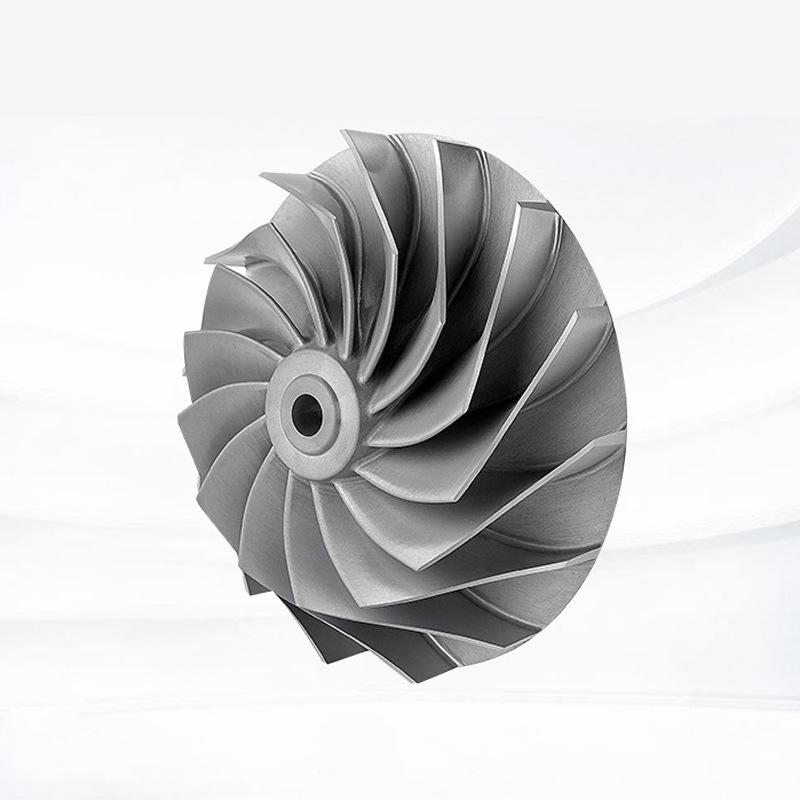

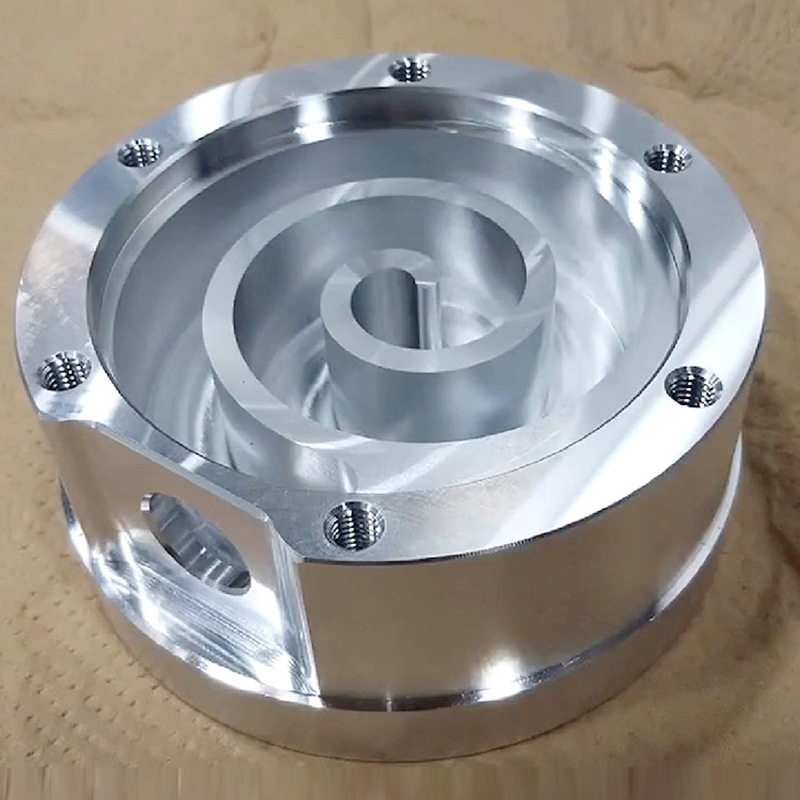

Function: Drilling, Tapping, Milling, Cutting, and Chamfering

Application Materials: Iron, Zinc, Steel, Stainless Steel, Tool Steel, Inconel, Hastelloy, Aluminum, Carbide, Titanium, Tungsten, Tantalum, Copper, Brass, Bronze, platinum etc.

Feature

High-end 5-axis CNC machine tools designed and developed by applying the world's advanced technology and the latest ideas, Applicable to machinery, aviation, automobile, medical equipment, mold and other industries.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote