Date: January 5, 2026

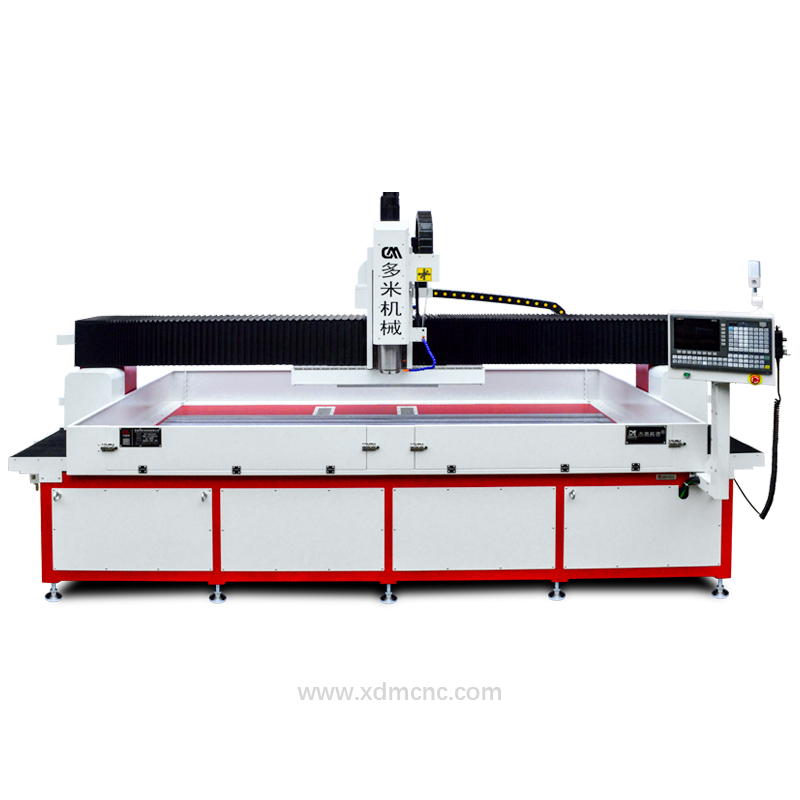

Equipment Name: Gantry-type CNC drilling and tapping machine

Equipment Model: DNC-4020N10

Location: Customer's Workshop, China

Today, a DUOMI gantry-type CNC drilling and tapping machine was officially put into production at the customer's workshop. After on-site installation, alignment, and operational checks, the machine began processing metal square tubes smoothly and stably.

The DUOMI CNC gantry drilling and tapping machine has been installed and commissioned at the customer's workshop.

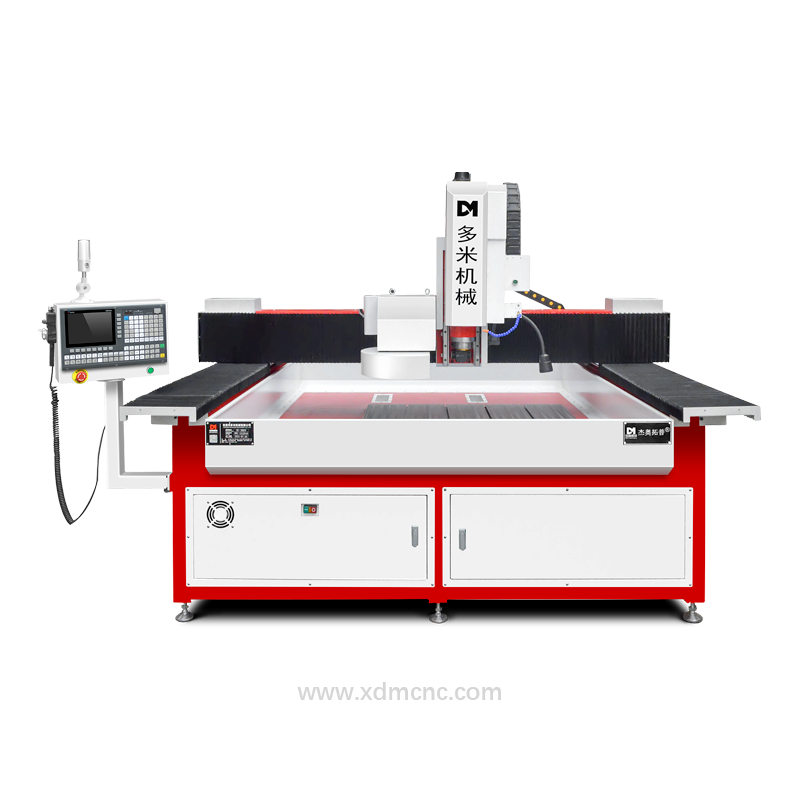

The customer is engaged in the manufacturing and fabrication of metal square tubes, which are widely used in structural frames and industrial assemblies. According to the production requirements, the machine is mainly used for continuous drilling and tapping operations on square tube profiles, ensuring consistent hole positions and uniform thread quality.

During the initial production run, the machine demonstrated stable performance under continuous operation. The gantry structure provides sufficient rigidity, which helps maintain accuracy when processing long or heavy square tubes. Hole positioning accuracy and tapping consistency met the customer's expectations, and the machining process was completed without visible deformation or burr issues on the tube surfaces.

The DUOMI CNC gantry drilling and tapping machine has been installed and commissioned at the customer's workshop.

Operators reported that the CNC control interface is clear and easy to use, allowing quick adjustment of drilling parameters based on different tube specifications. This improves overall production efficiency and reduces manual intervention during batch processing.

The successful commissioning marks the start of regular production for this DUOMI CNC drilling and tapping machine in the customer's workshop. It will now be integrated into the customer's daily manufacturing workflow, supporting stable output for metal square tube components.