DUOMI CNC (Duomi (Guangdong) Intelligent Equipment Co., Ltd.) is a China-based original manufacturer specializing in CNC drilling and tapping machines. The company focuses on practical machining requirements and long-term equipment reliability rather than short-term configuration stacking. This approach has shaped both the design philosophy of DUOMI CNC machines and their application across multiple industries.

DUOMI CNC Machine Advantages and Industry Applications

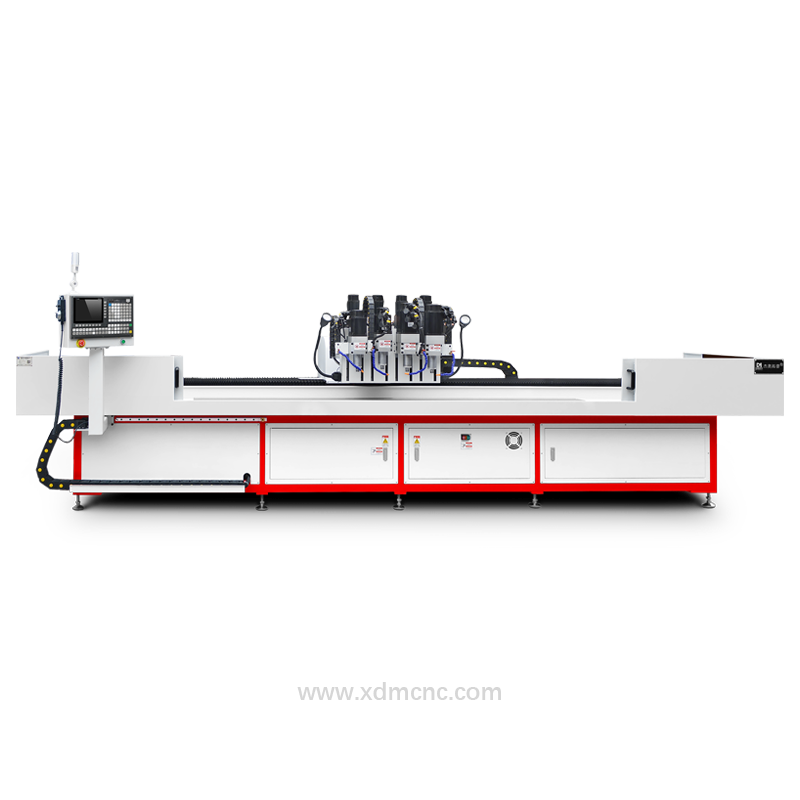

Manufacturing-Oriented Machine Design

One of the core advantages of DUOMI CNC machines lies in their manufacturing-oriented design. As a source factory, DUOMI CNC controls the full production process, including structural design, component selection, assembly, and functional testing. This allows machines to be developed based on real workshop conditions rather than theoretical specifications alone.

Machine frames and gantry structures are designed with rigidity and stability in mind, especially for continuous drilling and tapping operations. This is particularly important when processing long profiles, square tubes, or thicker metal components where vibration and deformation can directly affect hole accuracy and thread quality.

By manufacturing machines in-house, DUOMI CNC can continuously refine mechanical structures, spindle layouts, and motion systems based on accumulated production feedback. Improvements are integrated directly into new machines rather than treated as optional upgrades.

Consistent Drilling and Tapping Performance

DUOMI CNC drilling and tapping machines are developed to deliver consistent results during repetitive operations. Hole positioning accuracy, tapping depth control, and thread quality are maintained across batch production, which is critical for industrial manufacturing environments.

The machines are designed to support:

High-frequency drilling cycles

Stable tapping under continuous operation

Uniform hole quality across different materials

This consistency reduces the need for manual rework and secondary operations, helping customers maintain predictable production schedules.

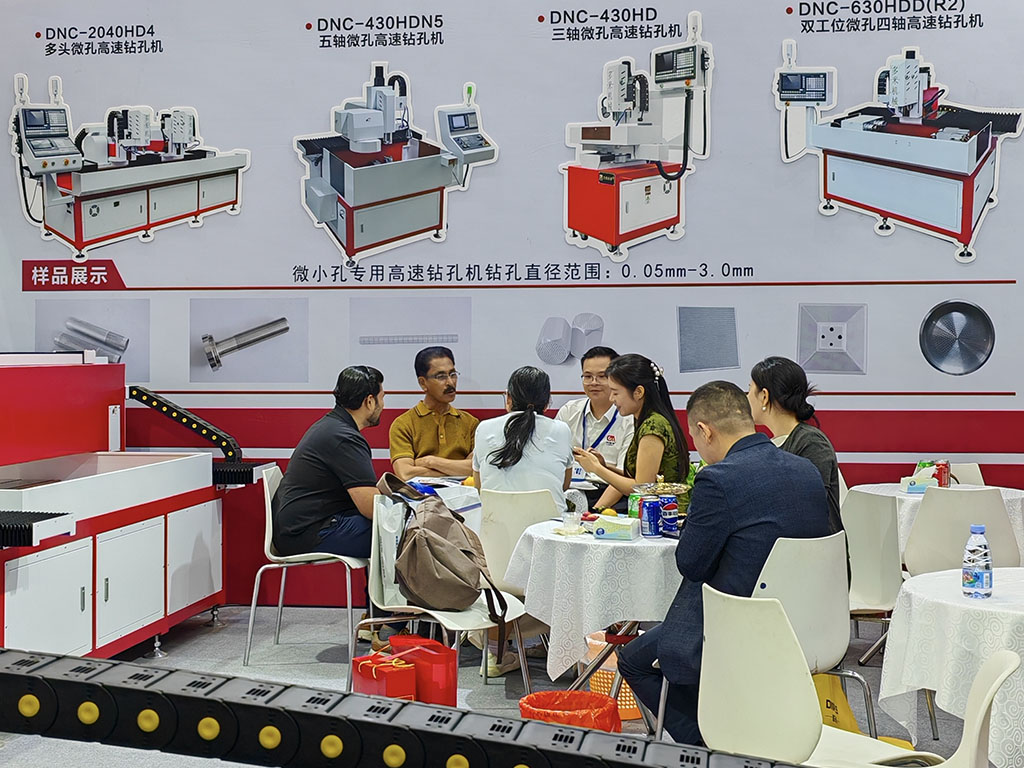

Foreign clients held contract negotiations with DUOMI's technical director

Flexibility for Different Materials and Workpieces

Another advantage of DUOMI CNC machines is their adaptability. The machines can be configured to process a wide range of materials, including carbon steel, stainless steel, aluminum alloys, and galvanized steel. Parameters can be adjusted to match different material hardness, wall thicknesses, and hole specifications.

This flexibility makes DUOMI CNC equipment suitable for workshops handling mixed production tasks, where switching between different workpieces is a regular requirement. Operators can adjust drilling and tapping parameters through the CNC control system without complex mechanical changes.

Integration into Existing Production Lines

DUOMI CNC machines are designed to integrate smoothly into existing production workflows. Whether installed as standalone units or incorporated into automated lines, the machines support standardized operation and maintenance practices.

Clear control interfaces and practical machine layouts allow operators to become familiar with the equipment quickly. This reduces training time and helps minimize downtime during installation and commissioning.

DUOMI has added another global partner to its network

Industry Applications

Metal Tube and Profile Processing

DUOMI CNC drilling and tapping machines are widely used in the processing of metal square tubes, round tubes, and structural profiles. Typical applications include:

Furniture frames

Fitness equipment components

Display racks and shelving systems

Structural supports and frames

The rigidity of the machine structure ensures stable drilling and tapping even on long or heavy profiles, maintaining alignment and thread quality.

Sheet Metal and Mold Manufacturing

In sheet metal mold production, accurate hole positioning and repeatable tapping are essential. DUOMI CNC machines are used for drilling and tapping mold plates, brackets, and auxiliary components. The machines support different plate sizes and thicknesses, helping mold manufacturers maintain precision across multiple projects.

The professionalism of DUOMI CNC equipment attracted many visitors' attention

Automotive and Transportation Components

Automotive and transportation industries require reliable machining for brackets, frames, and connecting components. DUOMI CNC machines are applied in drilling and tapping operations for metal parts used in vehicle structures, ensuring consistent assembly quality.

Electrical and Equipment Enclosures

Metal enclosures for electrical cabinets and industrial equipment often require precise hole patterns for assembly and mounting. DUOMI CNC machines support efficient drilling and tapping for these applications, improving production efficiency while maintaining dimensional accuracy.

Custom and Special Machining Applications

Because DUOMI CNC is a source manufacturer, machines can be adapted for specific applications such as thermal friction drilling, multi-spindle drilling, or specialized tapping processes. This makes the equipment suitable for customers with unique machining requirements beyond standard production tasks.

Long-Term Equipment Value

The advantage of working with DUOMI CNC goes beyond machine specifications. As an original manufacturer, DUOMI CNC provides clear documentation, stable machine configurations, and practical technical support throughout the equipment’s service life. This simplifies maintenance, upgrades, and future process optimization.

Rather than focusing on short-term performance claims, DUOMI CNC machines are built to operate reliably under real production conditions. This long-term perspective is a key reason why customers integrate DUOMI CNC equipment into their daily manufacturing operations.

DUOMI CNC combines manufacturing experience, practical engineering, and application-driven design to produce CNC drilling and tapping machines suited for real industrial environments. The machines offer stable performance, flexibility, and adaptability across multiple industries, making them a reliable choice for manufacturers seeking consistent and efficient drilling and tapping solutions.