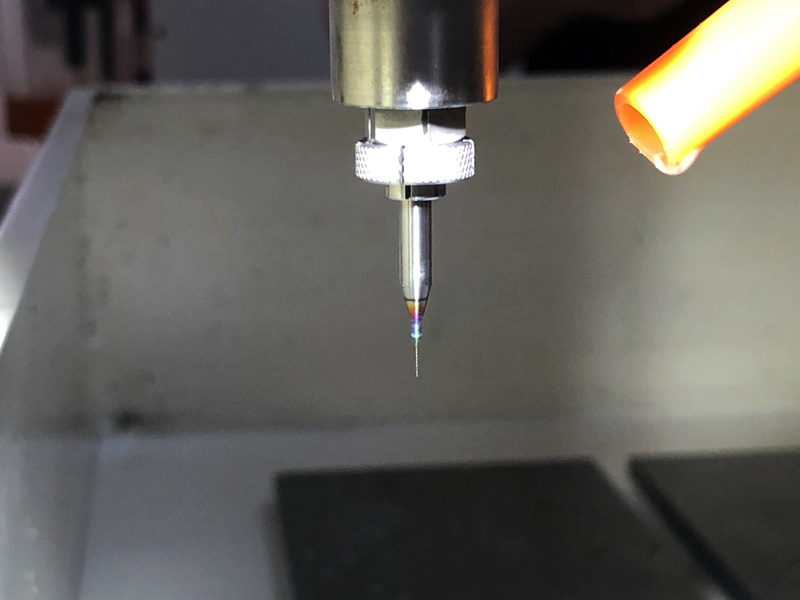

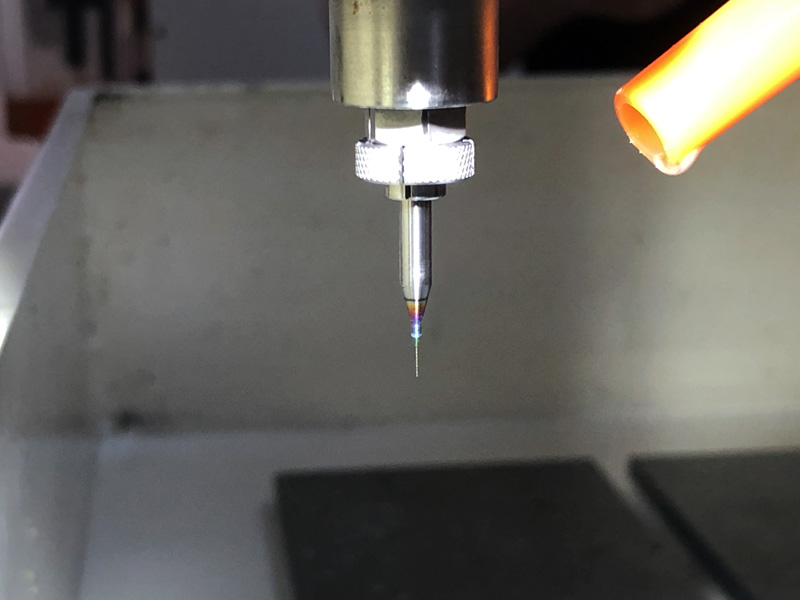

DUOMI CNC Drilling Machine: High-Precision Micro-Hole Drilling Down to 0.07mm for Advanced Manufacturing

As global industries push the limits of miniaturization and precision, the demand for ultra-micro drilling technology has soared. DUOMI CNC, a leading manufacturer of high-performance drilling systems, has developed an advanced CNC drilling solution capable of consistently drilling micro-holes as small as 0.07mm in diameter. This technological breakthrough enables manufacturers in the fields of electronics, medical devices, optical components, and micro-mechanical systems to achieve exceptional accuracy and reliability in ultra-fine hole processing.

Unmatched Micro-Drilling Performance

The DUOMI CNC drilling machine is specifically engineered for precision micro-hole applications. Equipped with ultra-high-speed spindles (up to 60,000 RPM), micron-level feed control, and rigid mechanical construction, the system can produce hole diameters from 0.07mm with minimal deviation in roundness and position.

Key features include:

Micro-hole capability: Stable and repeatable drilling from Ø0.07mm

High-speed spindle system: Enables ultra-fine cutting without material deformation

Advanced servo motion control: Ensures micron-level feed rates and position accuracy

Temperature compensation: Reduces thermal expansion errors in long-running operations

Clean drilling environment: High-pressure micro-lubrication and dust extraction prevent burr formation and hole clogging

Applications Across High-Tech Industries

The ability to drill such small and accurate holes opens up vast potential across several sectors:

Electronics – Micro vias and fine conductor holes for PCBs and semiconductors

Medical – Hypodermic needle manufacturing, surgical tools, microfluidic channels

Aerospace – Precision nozzles, fuel injectors, and sensor housings

Optics & Instrumentation – Micro-alignment holes, light transmission pathways

Watchmaking & Micro-Mechanics – Micro-axles, gear components, and pivots

With DUOMI's CNC system, industries can achieve tighter tolerances, finer finishes, and higher production efficiency even for the most demanding micro-scale parts.

Core Technologies Enabling Extreme Precision

The excellence of DUOMI's micro-drilling solution is powered by a fusion of key technologies:

Dynamic Rigidity and Vibration Damping: The machine bed is built with a high-density casting and precision-ground guide rails to eliminate micro-vibrations during high-RPM operations.

Closed-Loop Feedback System: Integrated linear encoders and spindle encoders provide real-time feedback, enabling nano-level adjustments.

CNC Software Suite: Proprietary control software with micro-drilling optimization mode ensures minimal tool wear and consistent results.

Tool Management System: Automatic tool calibration and breakage detection keep micro-tools in top condition.

Why Choose DUOMI for Micro-Hole CNC Drilling?

✔ Proven micro-hole performance down to 0.07mm

✔ Designed for 24/7 industrial-grade production

✔ Customizable configurations to suit specific material and hole depth needs

✔ International support and remote diagnostics

✔ Ideal for high-mix, small-batch precision part production

Whether you're working with stainless steel, copper alloys, titanium, or advanced composites, DUOMI's CNC platform delivers clean, burr-free micro-holes with high throughput and reliability.

Customer Success Case: Micro-Orifice Drilling for Medical Catheters

A medical device manufacturer needed to drill hundreds of micro-orifices, 0.07mm in diameter, into stainless steel catheter tips with ±0.005mm positional accuracy. Using DUOMI's CNC micro-drilling system, they reduced tool breakage by 40%, improved throughput by 60%, and achieved 100% quality pass rates under microscope inspection — setting a new benchmark in precision micro-fabrication.

Conclusion

The DUOMI CNC drilling machine is the go-to solution for manufacturers looking to push the boundaries of precision. With capabilities extending to ultra-micro drilling at just 0.07mm, it represents a new era of high-accuracy machining tailored to the demands of future-focused industries.

If your production demands precision at the micron scale, DUOMI CNC delivers the performance, consistency, and technical support you need to stay ahead of the competition.