Auto Feed Drill Machine – Boost Efficiency and Cut Costs with DUOMI CNC

When it comes to drilling metal, precision and productivity matter. Traditional manual drilling often slows down production, wastes labor, and creates inconsistent results. That's exactly why more manufacturers are switching to an auto feed drill machine. In this article, we'll explore how this advanced solution saves time, money, and headaches—while showing you why DUOMI CNC is the brand trusted worldwide.

Why Choose an Auto Feed Drill Machine?

The Problem with Manual Drilling

If you've ever run a workshop with conventional drill presses, you already know the pain points:

Inconsistent hole depth due to human error

Fatigue from repetitive manual feeding

Wasted time aligning and rechecking each part

High labor costs with low efficiency

Increased scrap rates and rework

Now imagine eliminating those frustrations with automation.

The Auto Feed Advantage

An auto feed drill machine automatically controls feed speed and drilling depth, so every hole is accurate and repeatable. No guesswork, no wasted effort. The operator simply sets the parameters, and the machine does the rest—consistently and precisely.

Key benefits include:

Improved productivity – Machines drill faster than manual labor

Reduced labor costs – One operator can manage multiple machines

Consistent quality – Every hole is uniform in depth and diameter

Less operator fatigue – Automation handles repetitive tasks

Higher safety – Less manual interaction with tooling

DUOMI CNC – Your Reliable Partner in Auto Feed Drilling

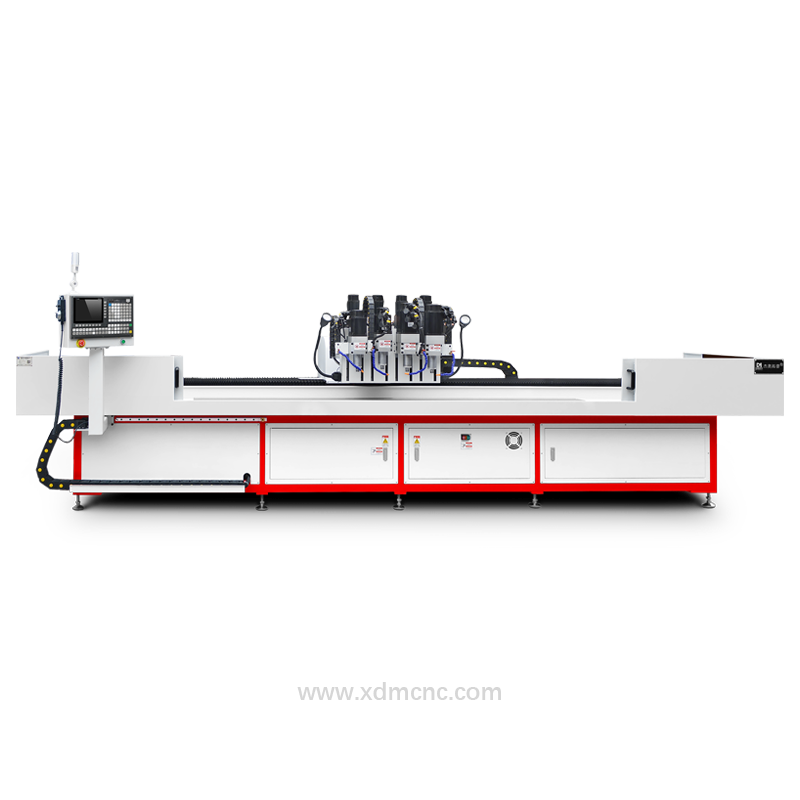

At DUOMI CNC, we specialize in designing and manufacturing advanced drilling and tapping machines that meet the demands of modern industries. Our auto feed drill machine models are built for heavy-duty performance, yet compact enough to fit into a variety of workshops.

What sets us apart?

High precision CNC control

Robust construction for long life

Flexible customization options

Fast delivery from multiple ports (Shanghai, Shenzhen, Qingdao, Guangzhou – or any port you specify)

Worry-free warranty and responsive after-sales service

Applications of Auto Feed Drill Machine

Furniture Manufacturing

From metal frames to aluminum profiles, furniture producers rely on clean and accurate holes. An auto feed drill machine ensures every joint fits perfectly, improving both durability and aesthetics.

Automotive and Motorcycle Parts

In automotive and motorcycle workshops, speed and consistency are everything. Our machines can handle steel, aluminum, and alloy components with ease, helping manufacturers meet strict industry standards.

Fitness Equipment Production

Fitness equipment requires strong joints and accurate assembly. An automated drilling solution guarantees strength, reliability, and safety for end users.

Aerospace and Electronics

Where precision tolerances are critical, DUOMI CNC's auto feed machines deliver micrometer-level accuracy, reducing rework and boosting output.

Auto Feed Drill Machine vs. Traditional Drilling

Labor Efficiency

Traditional drilling: Requires one worker per machine, manually feeding each part.

Auto feed drilling: One worker can manage multiple units, as machines run automatically.

Accuracy

Traditional drilling: Depth and alignment depend on operator skill.

Auto feed drilling: CNC control ensures precise repeatability every time.

Cost Impact

Traditional drilling: High labor costs, high scrap rate.

Auto feed drilling: Lower labor costs, reduced waste, and faster ROI.

Features of DUOMI CNC Auto Feed Drill Machine

Precision CNC System

Our machines use state-of-the-art CNC controllers for accurate drilling cycles. This means perfect alignment and depth, regardless of the material.

Heavy-Duty Spindle

Designed for continuous operation, the spindle maintains stability under high loads, reducing tool wear and ensuring long life.

Compact Design

Space is valuable in any workshop. DUOMI CNC offers machines that maximize efficiency without requiring huge floor space.

Easy Operation

Operators don't need years of experience. With user-friendly controls, anyone can quickly learn to program and run the machine.

Logistics and After-Sales Support

When you purchase from DUOMI CNC, you don't just get a machine—you get peace of mind.

Multiple shipping options: Shanghai, Shenzhen, Qingdao, Guangzhou, or any customer-designated port.

Fast delivery times: We work with trusted logistics partners to ensure your machine arrives quickly and safely.

Worry-free warranty: All DUOMI CNC machines come with a robust warranty and responsive after-sales service, so your investment is protected.

Customer Success Stories

Case 1: Furniture Manufacturer in Europe

A client producing metal furniture frames struggled with inconsistent drilling. After switching to DUOMI CNC's auto feed drill machine, they cut labor costs by 40% and doubled production efficiency.

Case 2: Automotive Supplier in Mexico

An auto parts factory adopted our machines for aluminum component drilling. Results: zero rejected parts in the first six months and a faster production cycle.

Case 3: Fitness Equipment Maker in the Middle East

Manual drilling created slowdowns and weak joints. With DUOMI CNC automation, the company increased output by 60% and eliminated quality complaints.

Why DUOMI CNC?

Proven expertise in CNC drilling and tapping solutions

Machines designed for global industries

Affordable prices without sacrificing quality

Professional support team with years of experience

Flexible shipping and fast turnaround

Final Thoughts

If you're tired of the inefficiencies of manual drilling, it's time to upgrade. An auto feed drill machine from DUOMI CNC gives you speed, precision, and cost savings that traditional methods simply can't match.

With worldwide shipping from Shanghai, Shenzhen, Qingdao, Guangzhou, or any port you specify—plus our worry-free warranty—you can invest with confidence.

Contact DUOMI CNC today and take the first step toward a more productive future.