In modern manufacturing, speed, accuracy, and repeatability are key. That's why companies across automotive, electronics, furniture, and metal fabrication industries are turning to Automatic Drilling and Tapping Machines and CNC Drilling and Tapping Machines from DUOMI CNC. These machines handle drilling and tapping in a single setup, reducing labor costs, minimizing rework, and improving overall production efficiency.

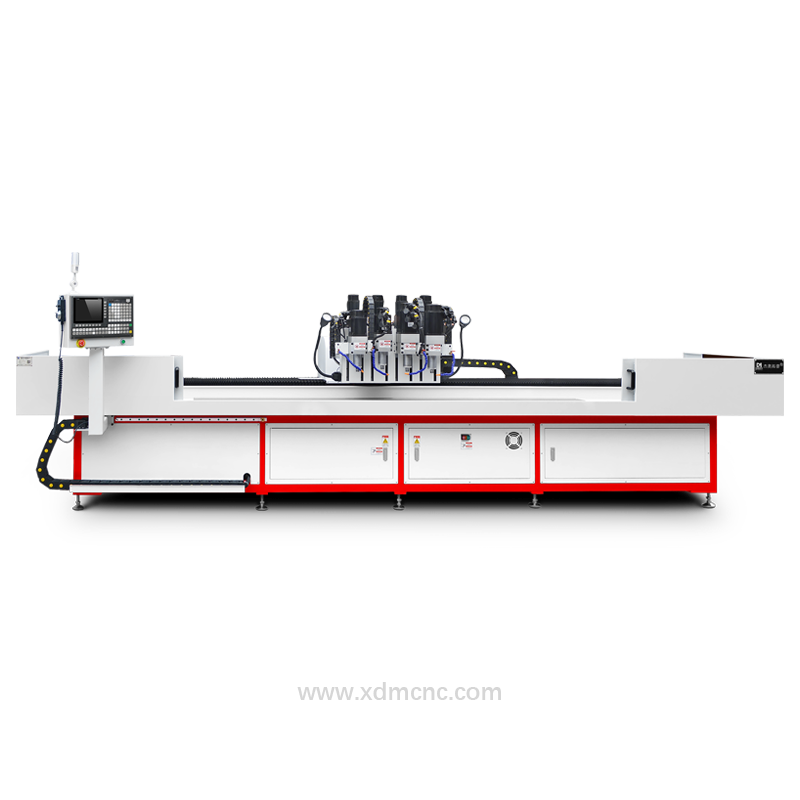

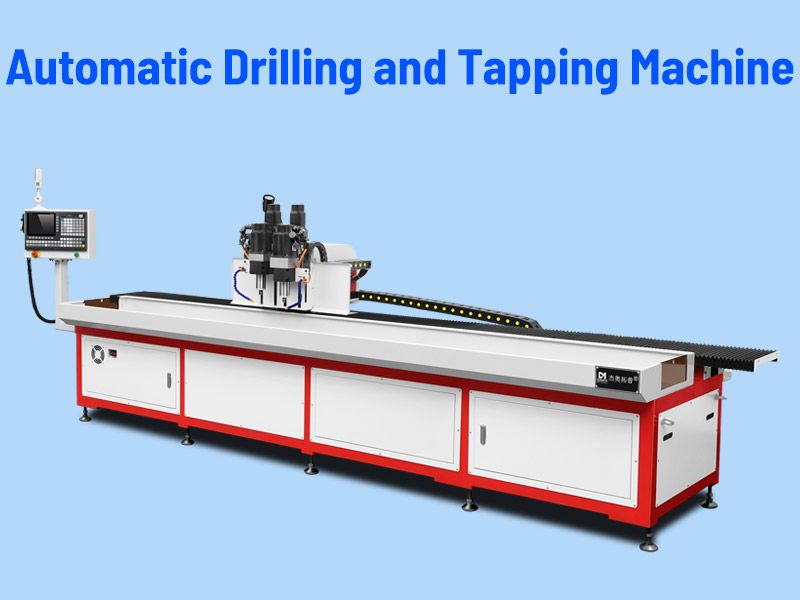

Automatic Drilling and Tapping Machine

Why Upgrade to Automatic and CNC Drilling and Tapping Machines

Pain Points of Traditional Drilling

Traditional manual drilling and tapping methods often struggle with:

Inconsistent hole quality

Misaligned threads

Slow production cycles

High labor costs

Frequent tool wear and downtime

These challenges lead to wasted material, missed deadlines, and lower customer satisfaction. For businesses working with die-cast aluminum housings, stainless steel components, or copper connectors, these limitations are particularly costly.

Benefits of DUOMI CNC Solutions

Our machines address these pain points by delivering:

High precision and repeatability – Perfectly aligned holes and threads every cycle.

Faster production – Reduce cycle times by automating multiple steps.

Reduced tool wear – Intelligent spindle control and optimized feed rates extend tool life.

Versatile material handling – Works on aluminum, stainless steel, copper, and more.

User-friendly operation – Simple programming and automatic tool changes improve workflow.

Real-World Customer Success Stories

Die-Cast Aluminum Housing Manufacturers

A major automotive client producing thousands of aluminum housings per week switched to a CNC Drilling and Tapping Machine. They reduced rejected parts by 70%, cut labor costs, and accelerated throughput. Holes and threads that once required multiple setups are now completed in a single automated cycle.

Stainless Steel and Heavy-Duty Fabrication

A customer producing thick stainless steel components for engine systems previously faced slow, multi-pass drilling with frequent tool changes. After adopting our Automatic Drilling and Tapping Machine, they cut cycle times by 40% while maintaining perfect thread quality. Another client in industrial machinery fabrication doubled their production of structural steel parts with minimal rework.

Electronics and Aluminum Shell Production

Small workshops and electronics manufacturers also benefit. One company producing aluminum shells for electronic devices went from manual tapping to CNC automation. The result: twice the throughput and consistent quality across every part, even for complex geometries.

Key Features of DUOMI CNC Machines

Multi-axis CNC control for accurate positioning

Automatic tool changer for fast, uninterrupted cycles

High-speed spindles with intelligent cooling

One setup for drilling, tapping, and chamfering

Ability to handle small holes and deep threads with precision

Fast Global Shipping and Worry-Free Warranty

DUOMI CNC ensures your machine arrives safely and quickly. We ship from major Chinese ports including:

Shanghai

Shenzhen

Qingdao

Guangzhou

✅ Machines can also be shipped from customer-specified ports.

✅ Fast lead times minimize production delays.

✅ Secure packaging and a comprehensive warranty guarantee your investment is protected.

Why Investing in CNC Automation Makes Sense

Businesses that upgrade to Automatic Drilling and Tapping Machines or CNC Drilling and Tapping Machines gain:

Increased production efficiency

Lower scrap and rework rates

Higher-quality finished parts

The ability to scale production without increasing labor

From die-cast aluminum housings to stainless steel panels and copper connectors, DUOMI CNC machines consistently deliver results that meet strict industry tolerances and customer expectations.

Final Thoughts

If your business relies on precision drilling and tapping, upgrading to a DUOMI CNC Automatic or CNC Drilling and Tapping Machine is a smart move. Customers worldwide—across automotive, electronics, and industrial fabrication—have seen measurable improvements in productivity, quality, and profitability. With flexible shipping from Shanghai, Shenzhen, Qingdao, or Guangzhou, plus customer-specified port options, fast delivery, and a worry-free warranty, DUOMI CNC ensures you can start producing high-quality components without delay.