How to Choose the Right Machine for Efficiency, Accuracy, and Long-Term Value

In modern manufacturing, CNC drilling and tapping machines play a critical role in improving productivity, consistency, and machining accuracy. From metal tubes and plates to structural components and industrial parts, these machines are widely used in furniture manufacturing, automotive components, fitness equipment, construction hardware, and many other industries.

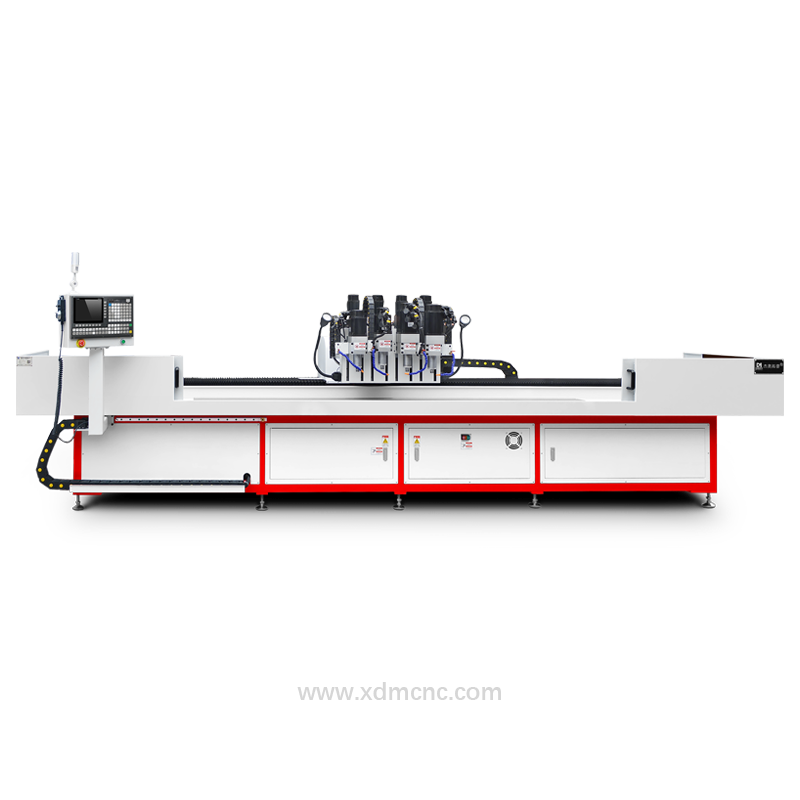

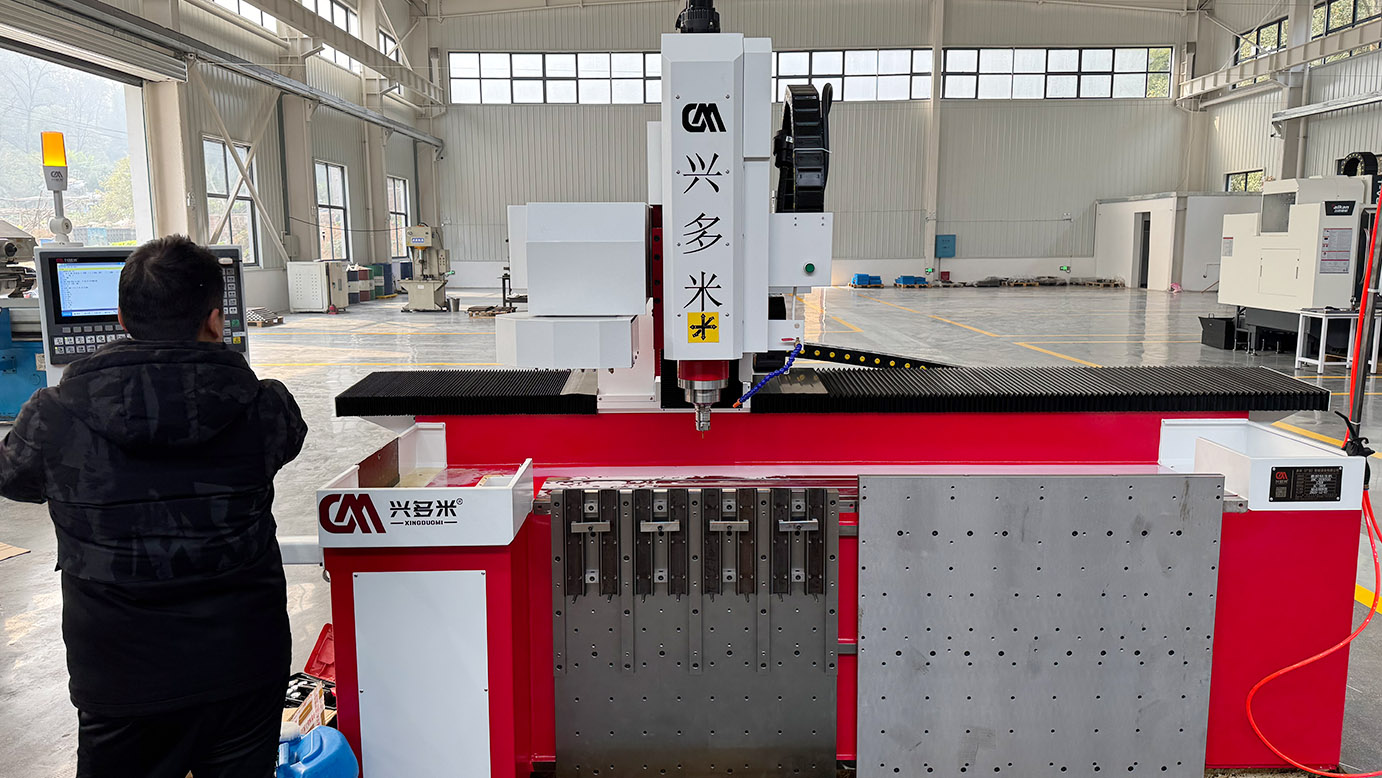

CNC Drilling and Tapping Machine Purchasing Guide

However, choosing the right CNC drilling and tapping machine is not a simple task. Specifications, configurations, automation levels, and suppliers vary greatly. This guide will walk you through the key factors to consider before purchasing, helping you make an informed and cost-effective decision.

1. Understand Your Application Requirements

Before comparing machine models or prices, clearly define what you need to machine.

Key questions include:

What materials will you process? (carbon steel, stainless steel, aluminum, etc.)

Are the workpieces plates, square tubes, round tubes, or profiles?

What is the maximum workpiece length?

Do you require micro holes, deep holes, or threaded holes?

Are you machining thin-wall parts that may require thermal drilling?

Understanding your application is the foundation of selecting the right CNC drilling and tapping solution.

2. Choose the Right Machine Structure

Different machining tasks require different machine structures.

Common options include:

Standard CNC drilling and tapping machines – suitable for plates and general components

Tube drilling and tapping machines with rotary axes – ideal for round and square tubes

Gantry-type drilling and milling centers – designed for large plates and heavy workpieces

Integrated drilling, tapping, and milling machines – for complex multi-process operations

If your products vary in shape or size, consider a machine with multi-function capability and flexible fixturing options.

3. Axis Configuration: 3-Axis, 4-Axis, or 5-Axis

Axis configuration directly affects machining capability and efficiency.

3-axis machines are suitable for basic drilling and tapping operations

4-axis machines add rotary indexing, ideal for tube processing without repositioning

5-axis machines enable complex multi-angle machining and higher automation

For tube manufacturers, a servo-controlled rotary axis allowing 360° indexing can significantly reduce setup time and improve accuracy.

4. Spindle Type and Performance

The spindle is the heart of any CNC drilling and tapping machine.

When evaluating spindle options, consider:

Mechanical spindle vs. motorized spindle

Taper type (e.g. BT30, BT40)

Maximum speed and torque

Rigidity and vibration control

A high-rigidity spindle ensures stable drilling and tapping, especially for high-speed machining and small-diameter holes.

5. Tool Changer and Automation Level

Automation is a key factor in reducing labor costs and increasing output.

Look for:

Automatic tool changers (ATC) with sufficient tool capacity

Servo-driven tool magazines for faster and more reliable tool changes

Tool changers that move with the spindle for flexible machining positions

For workshops producing multiple hole sizes and thread types, an ATC-equipped machine can dramatically improve efficiency.

6. Support for Thermal Drilling and Tapping

If you work with thin-walled metal tubes or sheets, thermal friction drilling is an important feature.

A capable CNC drilling and tapping machine should support:

High spindle speed and stable torque

Compatibility with thermal drilling tools

Smooth transition between conventional drilling and thermal drilling modes

This versatility allows one machine to handle both thick and thin materials, maximizing return on investment.

7. CNC Control System and Programming

A user-friendly CNC system improves productivity and reduces training costs.

Modern systems should offer:

Multiple programming methods

Direct CAD file import

Automatic program generation

Large program storage capacity

Stable and intuitive operation interface

Machines that do not require highly specialized programmers help factories save labor costs and reduce operational complexity.

8. Accuracy, Components, and Build Quality

Long-term performance depends heavily on machine quality.

Key elements to check:

Absolute-value servo motors for precise positioning

High-quality ball screws and linear guides (e.g. reputable global brands)

Automatic lubrication systems

Factory calibration using laser measurement equipment

A well-built machine should consistently maintain machining accuracy within tight tolerances.

9. After-Sales Service and Supplier Reliability

Purchasing a CNC drilling and tapping machine is a long-term investment.

Choose a supplier that provides:

Professional technical consultation before purchase

Installation and commissioning support

Operator training

Reliable spare parts supply

Long-term technical service

A source manufacturer with in-house production and engineering capabilities often offers better customization, faster support, and more competitive pricing.

10. Total Cost of Ownership, Not Just Price

The cheapest machine is rarely the most economical choice.

When evaluating cost, consider:

Machine lifespan

Stability and downtime risk

Maintenance requirements

Productivity and automation level

Energy consumption and labor savings

A high-quality CNC drilling and tapping machine delivers value through consistent performance, reduced labor, and long-term reliability.

Conclusion

Selecting the right CNC drilling and tapping machine requires careful evaluation of your machining needs, automation goals, and long-term production plans. By focusing on machine structure, axis configuration, spindle performance, control systems, and supplier reliability, you can confidently invest in a solution that enhances efficiency and competitiveness.

A well-chosen CNC drilling and tapping machine is not just equipment — it is a powerful tool for sustainable manufacturing growth.