Application Scope:

This machine is specifically designed for automatic drilling of the center section of gas stove burner caps. It is suitable for processing a variety of metal materials such as stainless steel, aluminum alloy, and iron. Ideal for gas stove manufacturers with high-volume, high-precision processing requirements.

Key Features:

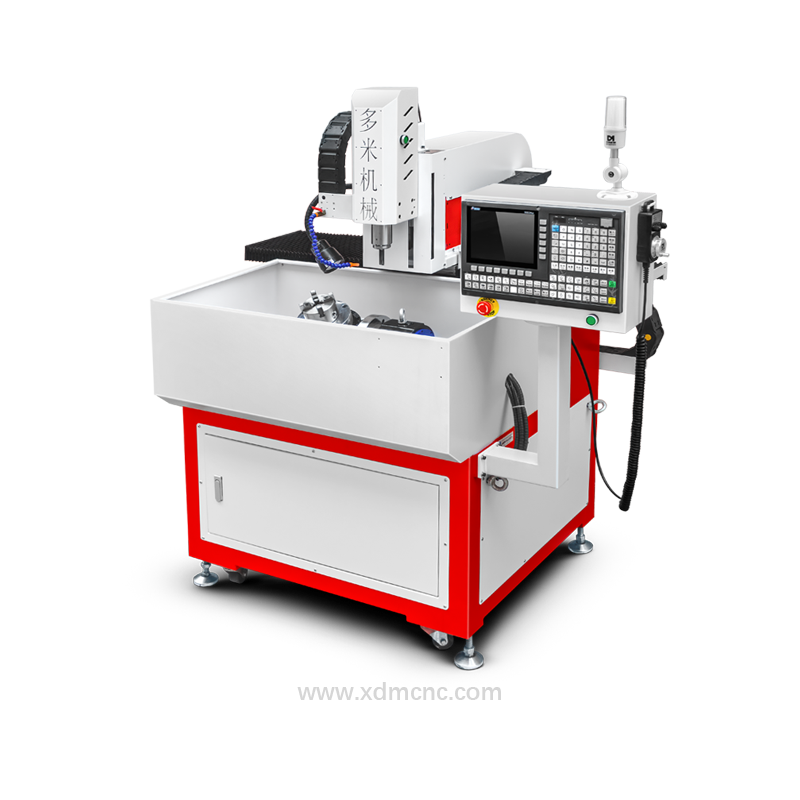

High-Precision CNC System: Equipped with a servo drive and CNC control for precise positioning and drilling.

Multi-Axis Synchronous Machining: Customizable with dual-axis or triple-axis structures to achieve multi-hole processing in a single operation.

Customized Clamping Fixtures: Tailor-made jigs ensure stable and accurate processing for different burner cap sizes.

High Automation Level: Supports optional robotic arm for automatic loading and unloading, significantly improving productivity.

User-Friendly Interface: Operated via a touchscreen interface with pre-set drilling modes for easy use and quick setup.

Robust Structure: Compact design with excellent vibration resistance, suitable for long-duration continuous operation.

Optional Features:

Automatic Loading/Unloading System.

CCD Vision Positioning System.

Automatic Chip Removal and Cooling System.

MES System Integration for Real-Time Data Collection and Traceability.