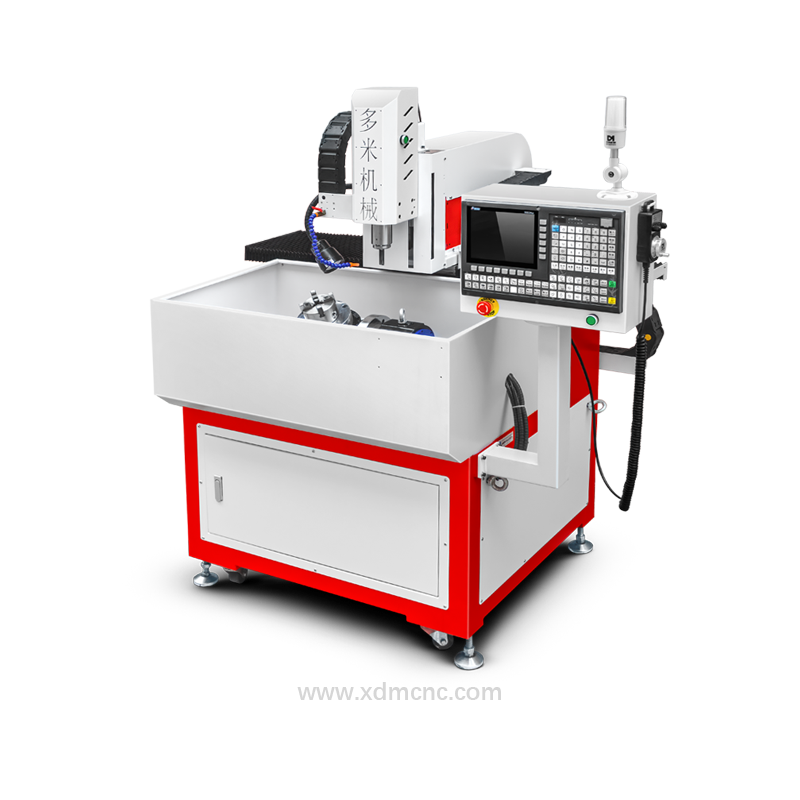

In the modern kitchen appliance manufacturing industry, precision and efficiency are key factors for producing high-quality gas stove components. The CNC Drilling Machine for Outer Ring Burner Cap of Gas Stove is an advanced solution designed to enhance the precision, speed, and consistency of drilling processes. This burner cap drilling machine ensures optimal gas flow, improves combustion efficiency, and guarantees durability for gas stove burner caps.

Features and Benefits

1. High-Precision Drilling

Equipped with state-of-the-art CNC technology, this machine achieves high-accuracy hole drilling on burner caps, ensuring uniform gas distribution for stable flames. The automatic burner cap drilling system guarantees precision and consistency in every operation.

2. Automated and Efficient Operation

Reduces manual labor

Increases production efficiency

Minimizes errors through computer-controlled automation

Optimized for gas stove burner hole drilling

3. Durable and Versatile Design

Built with high-strength materials, the machine is capable of handling different metal compositions, including copper, brass, and stainless steel. This CNC drilling equipment for burner caps ensures long-lasting performance.

4. Customizable for Various Gas Stove Designs

Manufacturers can adjust drilling patterns, hole sizes, and positions to match diverse gas stove models and customer specifications. Whether for stainless steel burner caps or brass burner caps, this machine provides maximum flexibility.

5. Enhanced Productivity and Cost Efficiency

With a high-speed spindle and multiple drilling heads, this burner cap CNC drilling machine drastically reduces production time, increasing output while reducing operational costs.

Applications

This CNC drilling machine is widely used in gas stove manufacturing plants, metalworking industries, and appliance production facilities. It is essential for companies specializing in kitchen appliance components, particularly for producing precision-engineered burner caps. The machine is also ideal for automatic burner hole drilling and CNC machining of gas stove parts.

Why Choose Our CNC Drilling Machine?

Superior accuracy in hole alignment

User-friendly interface for easy operation

Customizable drilling configurations

Energy-efficient design, reducing power consumption

Robust and long-lasting performance

Ideal for automated burner cap production

Conclusion

For gas stove manufacturers looking to improve product quality, streamline production, and ensure consistent burner cap performance, the CNC Drilling Machine for Outer Ring Burner Cap of Gas Stove is the ideal solution. Its combination of precision, automation, and durability makes it a must-have for modern industrial production. Whether you need CNC drilling for gas stove parts or automatic burner hole machining, this machine delivers outstanding performance.

If you're interested in boosting your manufacturing efficiency and achieving superior drilling precision, contact us today to learn more about our CNC drilling solutions!