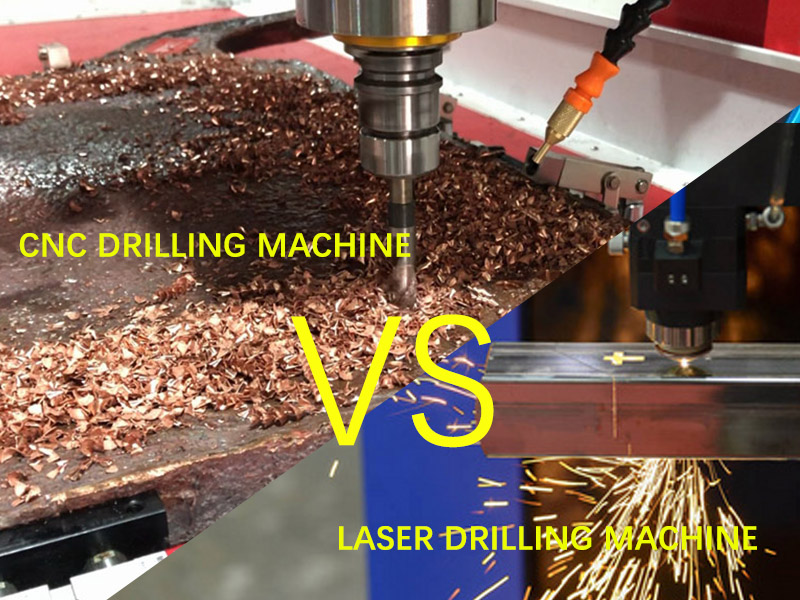

CNC Drilling Machine vs. Laser Drilling Machine: Key Differences and Competitive Advantages

In the evolving landscape of modern manufacturing, CNC drilling machines and laser drilling machines have become vital tools for precision hole-making in metalworking, fabrication, and engineering applications. While both technologies aim to create accurate holes, their operating principles, application scope, and cost-efficiency differ significantly. This article outlines the core differences and explores the unique advantages of CNC drilling machines over laser-based alternatives.

1. Working Principles: Mechanical vs. Thermal

CNC Drilling Machine uses a rotary cutting tool (drill bit) to physically penetrate the material and form holes. It operates through controlled mechanical movement along multiple axes, providing high torque and consistent depth.

Laser Drilling Machine, on the other hand, utilizes a focused beam of high-energy laser to vaporize or melt the material, creating holes with extreme heat in a non-contact process.

Key Takeaway: CNC drilling is mechanical and subtractive, while laser drilling is thermal and non-contact.

2. Material Suitability

CNC Drilling is ideal for a wide range of materials including steel, aluminum, brass, stainless steel, and alloys. It performs especially well with thick or high-tensile materials.

Laser Drilling is best suited for thin materials, such as sheet metal or delicate surfaces. Thicker materials often lead to thermal deformation or poor edge quality.

Advantage: CNC machines offer more material flexibility and consistency across various thicknesses.

3. Hole Quality and Precision

CNC Drilling Machines can achieve accurate hole diameters, clean edges, and precise depth control. They are ideal for thread tapping, countersinking, and multi-step holes.

Laser Drilling Machines provide high-speed processing, but may result in tapered holes, heat-affected zones (HAZ), and require post-processing for certain applications.

Advantage: CNC drilling ensures high structural integrity, especially for critical mechanical assemblies.

4. Cost and Maintenance

CNC Machines typically have lower operating costs. Tooling wear is manageable, and parts are widely available. Routine maintenance is straightforward.

Laser Machines have higher initial costs, require cooling systems, protective optics, and stringent safety measures, increasing long-term expenses.

Advantage: CNC drilling is more cost-effective for small to medium enterprises (SMEs) and mass production.

5. Application Fields

CNC Drilling Machines are widely used in:

Furniture and display rack industries

Fitness equipment and automotive frames

Structural steel and square tube processing

Heavy-duty sheet metal fabrication

Laser Drilling Machines are more common in:

Electronics and microfabrication

Aerospace turbine components

Medical devices and precision tooling

Advantage: For large-format metal drilling, CNC drilling machines are unmatched in performance and durability.

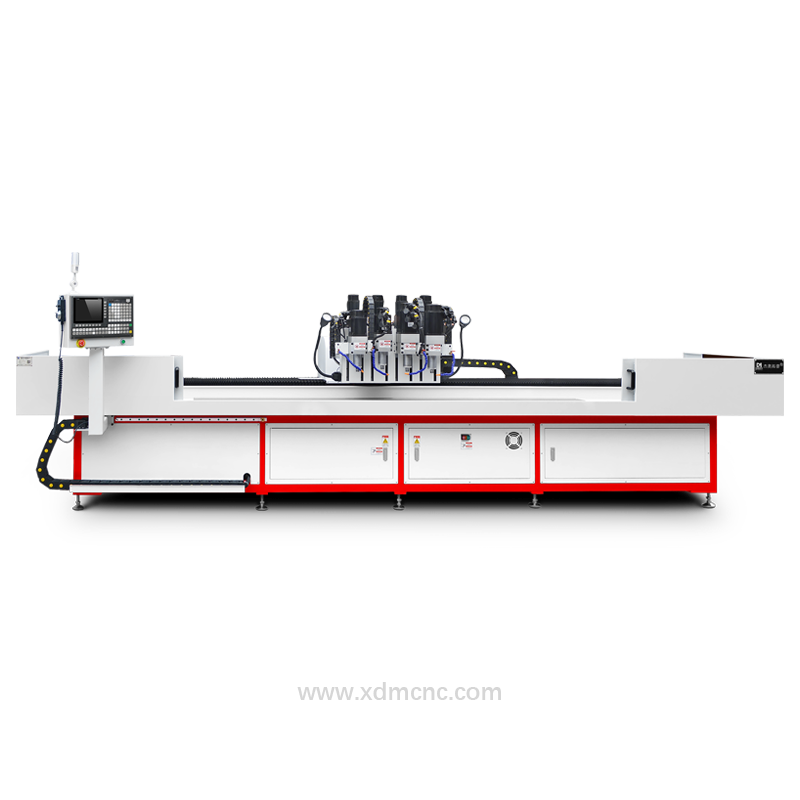

Why Choose CNC Drilling Machines for Your Production Line?

If your operations involve steel tubes, thick plates, or mass drilling with tapped threads, CNC drilling machines provide a reliable, efficient, and scalable solution. With flexible tooling options, integrated automation, and stable mechanical output, CNC systems can help increase production throughput while reducing operational costs.

At DUOMI CNC, we specialize in manufacturing advanced gantry-type CNC drilling machines for large-format sheet metal and tube processing. Our machines are trusted by clients in furniture, automotive, construction, and industrial equipment manufacturing across the globe.

Conclusion

While both CNC drilling and laser drilling have their respective strengths, CNC drilling machines remain the top choice for robust, high-volume metalworking applications. Their versatility, economic efficiency, and hole quality make them an indispensable asset in today’s competitive manufacturing environment.

Looking for a Reliable CNC Drilling Machine Manufacturer?

Contact us today to learn more about our customizable CNC solutions.