Applications of Gantry-Type CNC Drilling and Tapping Machines

In today's fast-paced manufacturing world, the demand for high-efficiency, precision machining solutions has never been greater. Gantry-type CNC drilling and tapping machines have emerged as a powerful solution across a variety of industries. Their robust design, large working area, and automated capabilities make them an ideal choice for drilling and tapping operations on large metal sheets, structural steel, aluminum profiles, and more.

Click on the image for more details

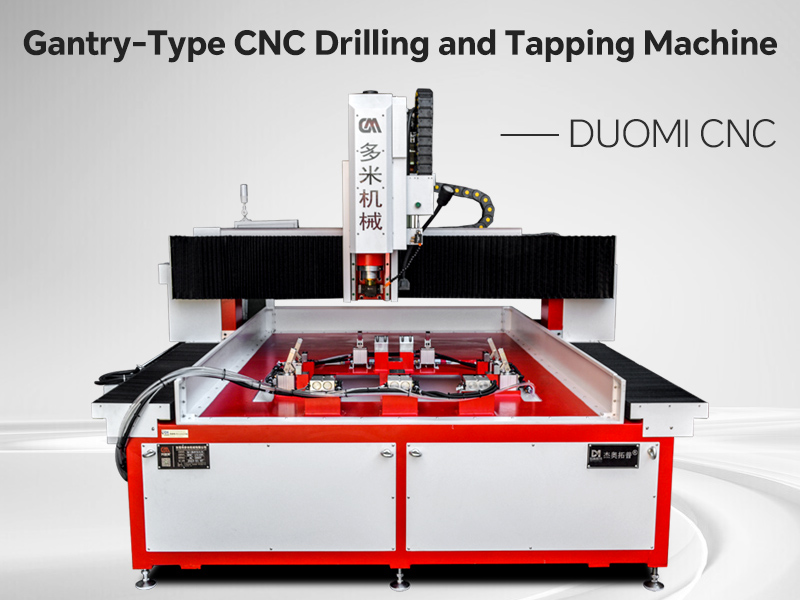

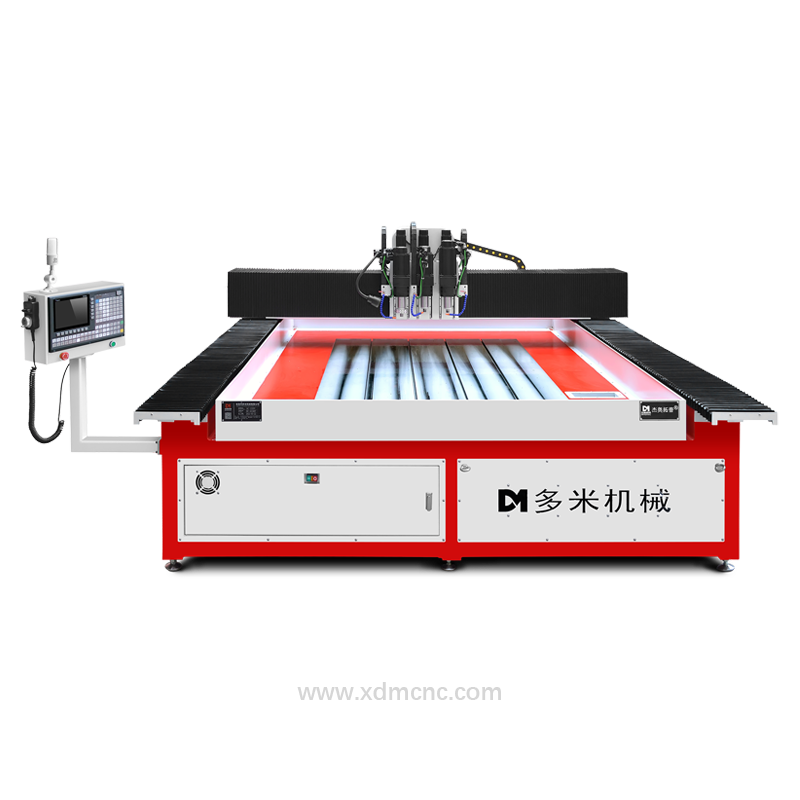

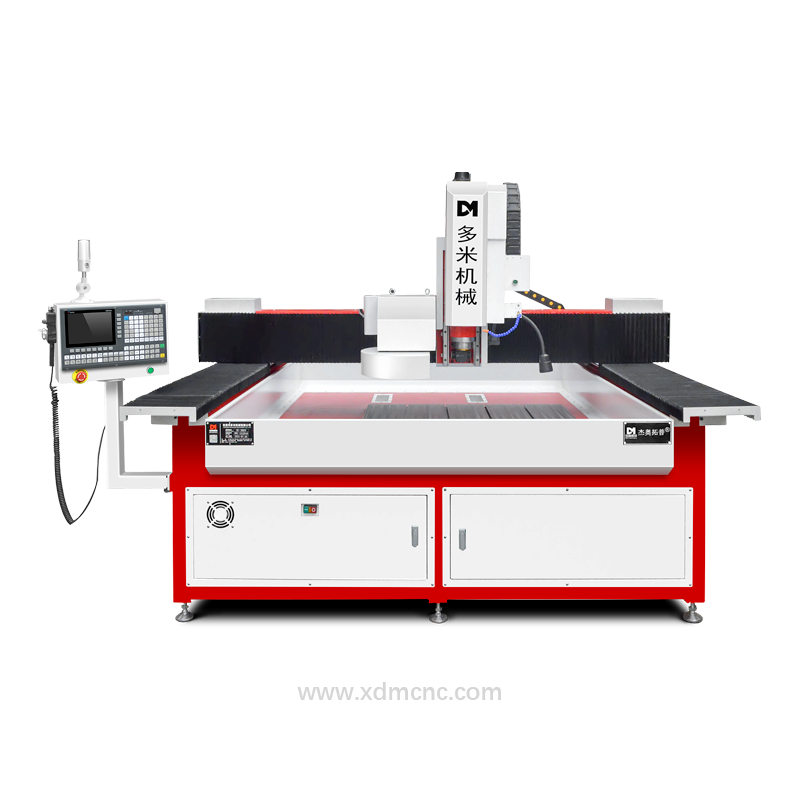

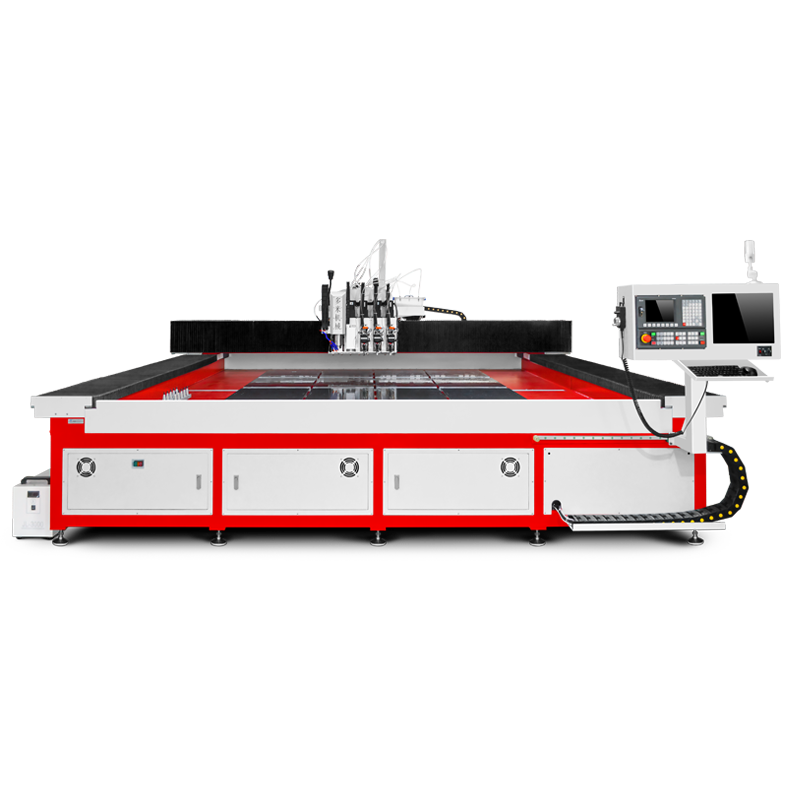

What Is a Gantry-Type CNC Drilling and Tapping Machine?

A gantry-type CNC drilling and tapping machine is a high-performance industrial tool designed for precision hole-making and threading tasks on medium to large workpieces. The machine features a gantry-style structure where the bridge spans over the worktable, providing excellent stability and allowing the spindle to move freely in the X, Y, and Z axes. With CNC control, operators can automate complex drilling patterns and tapping sequences with remarkable accuracy and repeatability.

Key Applications Across Industries

1. Structural Steel Fabrication

In steel structure production, such as in buildings, bridges, and infrastructure, gantry CNC drilling machines are used to create bolt holes, anchor points, and threaded connections quickly and precisely. Their ability to process large H-beams, I-beams, and flat plates makes them indispensable for construction firms and metal fabricators.

2. Aluminum Panel and Profile Processing

These machines are widely used in the processing of aluminum curtain wall panels, window frames, and architectural profiles. Their high-speed tapping and smooth drilling performance help reduce cycle time and improve consistency, especially in mass production environments.

3. Machinery Parts Manufacturing

From heavy equipment components to large mechanical bases, gantry CNC drilling and tapping machines play a key role in producing high-strength threaded holes and alignment bores with tight tolerances.

4. Automotive and Truck Frames

The automotive industry, particularly manufacturers of commercial vehicle chassis and frames, benefits from gantry-style machines for accurately drilling multiple holes along long metal frames, reducing manual error and improving production efficiency.

5. Power Transmission and Electrical Panels

These machines are also used to process electrical enclosures, busbar frames, and substation panels where precision holes and tapped threads are critical for wiring, component mounting, and grounding.

Advantages of Using Gantry-Type CNC Drilling & Tapping Machines

Large Working Area: Perfect for oversized workpieces and multi-position drilling.

High Precision & Repeatability: CNC control ensures consistent results.

Integrated Tapping: Eliminates secondary tapping steps, saving time.

Reduced Labor Costs: Automated processes require fewer manual operations.

Versatile Applications: Suitable for a wide range of materials including steel, aluminum, copper, and composites.

Why Invest in a Gantry CNC Drilling and Tapping Machine?

By incorporating a gantry-type CNC drilling and tapping machine into your production line, you significantly improve throughput, reduce rework, and enhance the overall quality of your components. These machines are built to meet the high demands of modern manufacturing and are a long-term investment in productivity.

Duomi CNC 2025 Gantry-Type CNC Drilling, Tapping & Milling Machine – Real Application Cases

Looking for a Reliable Gantry CNC Drilling Solution?

[DUOMI CNC] specializes in manufacturing state-of-the-art CNC drilling and tapping machines tailored to your production needs. With global support, professional training, and customized solutions, we help you take your business to the next level.