CNC Drilling Machine with Auto Tool Changer: The Next Step in Smart Manufacturing

In the modern manufacturing world, speed, precision, and automation define competitiveness. Every second saved on the production line can translate into thousands of dollars in output. Among the most transformative innovations in recent CNC technology is the CNC drilling machine with an auto tool changer — a system designed not just to drill, but to think and adapt.

For decades, tool changing has been one of the silent time killers in machining processes. Manual tool swaps slow production, interrupt precision, and expose tools to errors. But now, the auto tool changer (ATC) changes everything.

In this article, we’ll explore how a CNC drilling machine equipped with an auto tool changer is reshaping metalworking, how it eliminates human downtime, and why leading CNC drilling machine manufacturers are embracing this intelligent automation as a new industry standard.

What Makes an Auto Tool Changer So Important

A CNC drilling machine performs a variety of operations — from pilot drilling to tapping, reaming, and countersinking. Traditionally, each task required a separate tool, meaning the operator had to pause production, manually replace the drill bit, recalibrate, and resume drilling.

That approach worked — but it wasn’t efficient. Every manual change meant minutes lost. Multiply that by hundreds of cycles per day, and you get hours of downtime.

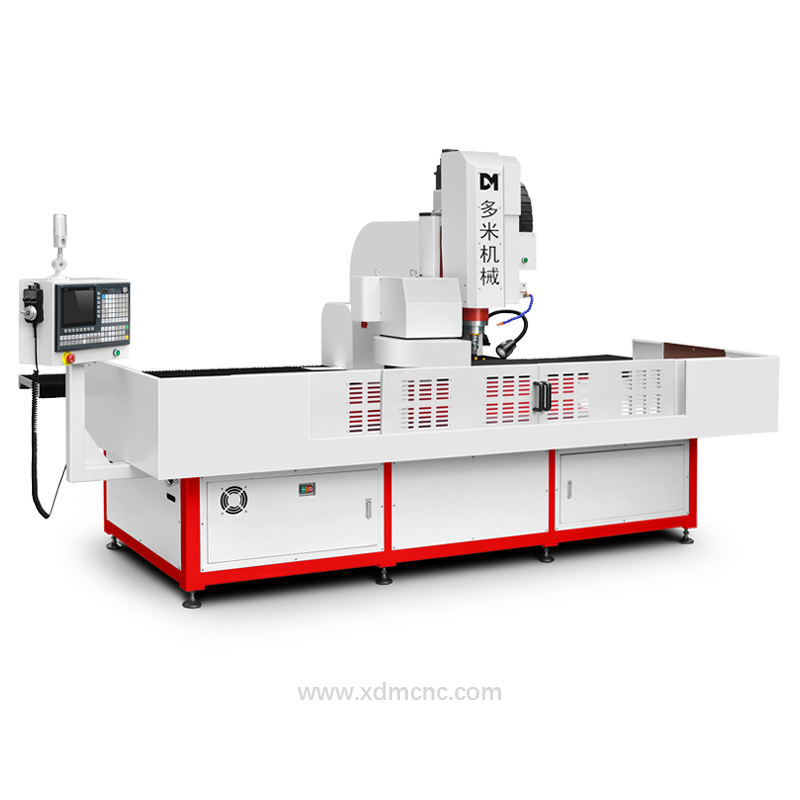

CNC Drilling Machine with Auto Tool Changer

An auto tool changer (ATC) solves this by automatically switching between tools in seconds. The system identifies the correct tool, retrieves it from the magazine, locks it into the spindle, and resumes drilling — all without operator intervention.

The result? Continuous production, consistent precision, and zero wasted time.

How the CNC Drilling Machine with Auto Tool Changer Works

The beauty of this system lies in its simplicity and synchronization.

Tool Magazine Storage

The auto tool changer typically includes a magazine (disk-type or chain-type) that holds 10 to 40 different tools, depending on the model and application.Automatic Tool Selection

Based on the CNC program, the system automatically identifies which drill, tap, or cutter is needed next.High-Speed Change Cycle

Within seconds, the current tool is released and the new one is locked in place with precision air or hydraulic control.Smart Sensor Feedback

Each tool is registered, tracked, and verified — ensuring that no wrong tool is ever used, reducing costly human errors.

This automated sequence keeps your CNC drilling machine running efficiently and continuously, even during complex multi-step drilling operations on aluminum, steel, or stainless steel parts.

Key Advantages of CNC Drilling Machines with Auto Tool Changer

Let’s break down what truly sets these machines apart from conventional systems.

1. Zero Downtime, Maximum Productivity

The ATC system eliminates manual pauses during tool changes, keeping your spindle in motion — which is where profits are made.

Studies show that switching to a CNC drilling machine with auto tool changer can increase throughput by 40%–60%, simply by reducing idle time.

2. Consistent Precision and Accuracy

Each automatic change is executed under CNC control, guaranteeing repeatable accuracy down to microns. This eliminates the minor alignment errors common in manual changes, which can affect hole positioning and quality.

The consistency is especially valuable when drilling stainless steel or other high-tensile materials that require precise feed rates and torque control.

3. Extended Tool Life and Protection

Leading CNC drilling machine manufacturers integrate smart tool monitoring systems that track wear, detect overload, and manage tool rotation schedules automatically.

When one drill bit shows signs of wear, the ATC can automatically replace it with a backup — extending total uptime and ensuring smooth performance.

This predictive maintenance capability protects both your tools and your workpieces.

4. Multi-Function Machining in One Setup

An ATC-enabled machine doesn’t just drill — it can tap, ream, chamfer, and countersink within a single cycle.

Instead of moving parts between multiple machines, operators can complete complex machining operations on one CNC platform. The result is a significant reduction in setup time and human labor costs.

5. Enhanced Safety and Ease of Operation

Manual tool changing can expose operators to hot chips, sharp tools, and heavy components. With the ATC system, these risks disappear.

The machine performs tool changes automatically, making the entire operation safer, smoother, and more ergonomic — a major advantage for factories operating 24/7.

Why It Matters Most in Stainless Steel Drilling

Drilling stainless steel remains one of the most demanding challenges in CNC machining. The material’s density and hardness often lead to heat buildup, bit wear, and eventual breakage.

The CNC drilling machine with auto tool changer addresses this problem directly:

Tool Rotation & Backup: If one bit shows signs of overheating, the system can switch to a fresh tool instantly.

Programmed Tool Optimization: Feed speed and torque are automatically adjusted per tool to prevent breakage.

Cooling Synchronization: Coolant flow is coordinated with each new tool, ensuring stable cutting conditions at high RPM.

This synergy keeps tool integrity intact — even during long production runs on stainless steel parts.

Inside a Modern CNC Drilling Machine Manufacturer’s Workshop

A world-class CNC drilling machine manufacturer doesn’t just assemble machines; it engineers ecosystems.

At DUOMI CNC, for instance, every drilling system is developed through digital twin modeling and real-world load simulation. Each auto tool changer is tested under continuous load conditions to ensure flawless performance.

From spindle design to servo control tuning, DUOMI’s production philosophy centers on three pillars:

Durability — Machines built for 10+ years of service life under continuous operation.

Adaptability — Flexible ATC configurations supporting various tool types and materials.

Precision — Servo-controlled alignment accuracy within ±0.01 mm, even during high-speed drilling cycles.

This combination is what makes DUOMI CNC a trusted CNC drilling machine manufacturer among clients in automotive, aerospace, energy, and structural steel industries worldwide.

Comparing Traditional vs. Auto Tool Change Drilling Systems

| Feature | Conventional CNC Drilling Machine | CNC Drilling Machine with Auto Tool Changer |

|---|---|---|

| Tool Change Time | 3–5 minutes per cycle | 3–5 seconds |

| Human Involvement | High | Minimal |

| Accuracy | Operator-dependent | CNC-controlled precision |

| Tool Life Management | Manual tracking | Smart system integration |

| Ideal for Stainless Steel | Limited | Excellent |

| Productivity | Moderate | Up to 60% higher |

This data clearly shows why factories around the world are transitioning toward ATC-equipped systems.

Integration with Smart Manufacturing (Industry 4.0)

The latest CNC drilling machines are designed for connected production lines.

Through IoT-enabled control systems, each auto tool changer can send real-time data on tool usage, spindle performance, and maintenance alerts to factory dashboards.

Imagine a smart alert notifying you when a drill bit is nearing its lifespan, or a report showing which tool combinations deliver the best results on a specific stainless steel grade.

This is no longer the future — it’s the present of intelligent manufacturing, powered by advanced CNC drilling machine manufacturers.

Applications Across Industries

A CNC drilling machine with auto tool changer isn’t just for one type of production. Its flexibility makes it ideal across multiple industrial sectors:

Automotive Components: Precision hole drilling and tapping for brackets, manifolds, and engine blocks.

Aerospace Structures: Multi-material drilling for titanium, aluminum, and stainless steel components.

Furniture & Display Systems: Fast, consistent drilling of square or round tubing.

Hydraulic Systems: Accurate drilling of ports and channels in valve blocks.

Fitness Equipment Manufacturing: Seamless drilling and tapping on thick-walled steel pipes.

What Makes a Reliable CNC Drilling Machine Manufacturer

Choosing the right CNC drilling machine manufacturer is crucial for long-term value. Look for these traits:

Engineering Expertise: Proven experience in high-speed and multi-tool systems.

After-Sales Support: Local service, training, and spare parts availability.

Customization Capability: Flexible options for spindle count, tool capacity, and automation integration.

Reputation: Verified installations and customer success stories.

Top-tier manufacturers like DUOMI CNC provide not just machines, but complete productivity solutions — from consultation to long-term maintenance.

Performance That Translates to Real ROI

Manufacturers who adopt ATC-equipped CNC systems report tangible improvements:

Tool Change Speed: Reduced from minutes to seconds.

Cycle Time Reduction: 40–70% faster throughput.

Tool Life Extension: Up to 200% longer average lifespan.

Energy Efficiency: Reduced spindle idle time equals lower power consumption.

These numbers directly influence profitability — giving businesses faster payback and sustainable growth.

Customer Success Stories

“Our DUOMI CNC machine runs non-stop, drilling and tapping stainless steel tubes. The auto tool changer keeps production flowing — no downtime, no errors.”

— Mr. Lin, Metal Fabrication Plant

“We replaced three older machines with one ATC-enabled model. It handles everything from drilling to chamfering automatically. The efficiency gains are remarkable.”

— Ms. Rivera, Aerospace Supplier

These real-world results demonstrate why automation and smart tooling are no longer luxuries — they’re the new standard.

Conclusion: The Smart Way Forward

In 2025, industrial success is measured not just by how well a machine performs, but by how intelligently it adapts. The CNC drilling machine with auto tool changer represents that intelligence — combining automation, durability, and unmatched precision.

By eliminating manual tool changes, reducing downtime, and protecting tools, it sets a new benchmark in modern manufacturing.

If your goal is to drill smarter, faster, and longer, it’s time to partner with an innovative CNC drilling machine manufacturer like DUOMI CNC — where every machine is engineered to maximize your productivity and precision.