Multi Spindle CNC Drilling Machine Manufacturer: Redefining Precision and Speed in Metalworking

In today’s fast-paced manufacturing landscape, productivity and precision define success. Industries dealing with stainless steel drilling face a recurring challenge — how to achieve high-speed, accurate drilling without breaking drill bits or sacrificing quality.

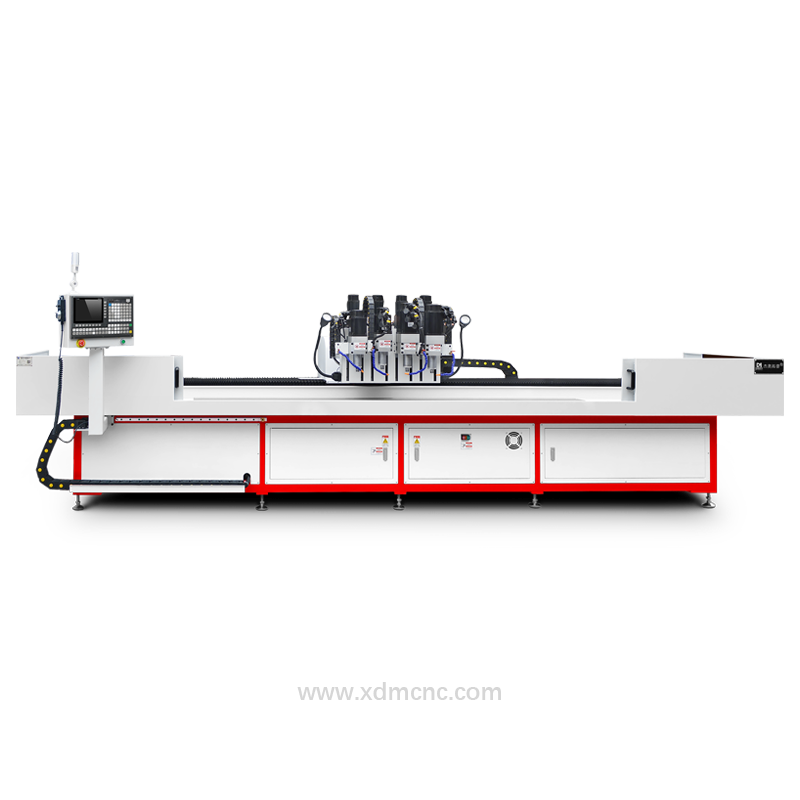

Multi Spindle CNC Drilling Machine Manufacturer

That’s where multi spindle CNC drilling machines come into play. Designed for simultaneous drilling operations, these advanced systems transform production lines by cutting cycle time, reducing tool wear, and delivering perfectly aligned holes every time.

And behind every great machine, there’s an innovative CNC drilling machine manufacturer that makes it possible.

The Power of Multi Spindle CNC Drilling Machines

A multi spindle CNC drilling machine is engineered to perform multiple drilling operations simultaneously, using two, three, or even six spindles that move in synchronization.

Unlike traditional single-head drills, which handle one hole at a time, multi-spindle machines drastically improve efficiency — drilling several holes on stainless steel, aluminum, or carbon steel components in a single cycle.

For manufacturers working with stainless steel — a notoriously tough material — this technology is a breakthrough. It minimizes vibration, optimizes torque, and ensures tool longevity, even in high-speed production environments.

Why Stainless Steel Drilling is So Demanding

Stainless steel is strong, durable, and resistant to corrosion — but these same properties make it difficult to drill. The metal’s hardness generates excessive heat during cutting, causing premature drill bit breakage, chip adhesion, and tool wear.

Conventional drilling setups often fail to manage heat and maintain consistent torque, resulting in frequent downtime and inconsistent hole quality.

However, a multi spindle CNC drilling machine eliminates these issues through advanced cooling, smart feed control, and real-time monitoring systems.

Technology That Prevents Drill Bit Breakage

The new generation of CNC drilling machines — especially multi spindle types — integrates cutting-edge features designed to protect drill bits and extend tool life. Let’s explore how:

Dynamic Feed Adjustment

The machine continuously monitors cutting resistance and automatically adjusts the feed rate. This prevents excessive pressure on the drill, especially during stainless steel drilling.High-Pressure Coolant Systems

Coolant is delivered precisely to the cutting zone, quickly removing chips and lowering tool temperature. This helps maintain sharpness and prevents tip deformation.Vibration Suppression

Rigid machine frames, precision bearings, and servo-driven spindles eliminate micro-vibrations that can cause uneven drilling or sudden breakage.Torque Synchronization

Each spindle’s torque is balanced automatically to ensure equal cutting force, minimizing stress on the tools even in multi-hole drilling operations.Adaptive Smart Monitoring

The CNC controller detects load changes and compensates instantly, ensuring consistent drilling depth and protecting the bit from overload.

As a result, manufacturers can achieve continuous drilling on stainless steel for thousands of holes without a single broken bit — saving both time and cost.

Why Choose a Multi Spindle System Over a Single Spindle Machine

While a single-head CNC drilling machine has its place in prototyping and small-scale production, multi spindle models are the future for industrial-scale efficiency.

| Feature | Single Spindle | Multi Spindle CNC Drilling Machine |

|---|---|---|

| Drilling Speed | Moderate | Up to 4× faster |

| Hole Accuracy | High | Equal or higher |

| Tool Life | Shorter | Up to 3× longer |

| Ideal for Stainless Steel | Limited | Excellent |

| Cycle Time | Longer | Reduced by 60%–80% |

This leap in efficiency makes the multi spindle CNC drilling machine indispensable for manufacturers in automotive, aerospace, furniture, fitness, and heavy machinery industries.

How Leading CNC Drilling Machine Manufacturers Are Innovating

A true CNC drilling machine manufacturer doesn’t just produce equipment — it designs productivity. Leading companies like DUOMI CNC have revolutionized drilling systems with integrated automation, precision spindles, and intelligent software.

Key Innovations Include:

Multi-Axis Control: Supports simultaneous drilling and tapping.

Modular Spindle Configuration: Allows flexible setups for different part geometries.

Automatic Tool Changer (ATC): Reduces downtime between operations.

Servo Feed Technology: Ensures consistent torque and prevents bit overload.

Central Lubrication & Cooling: Keeps every spindle running smoothly for continuous operation.

These innovations ensure that each CNC drilling machine delivers exceptional reliability, consistency, and cost efficiency — even under the most demanding production conditions.

Precision in Every Hole — Especially for Stainless Steel

For industries dealing with stainless steel products such as valves, manifolds, brackets, or exhaust systems, the margin for error is zero. Hole misalignment or burr formation can compromise the entire assembly.

With a multi spindle CNC drilling machine, precision is guaranteed. The synchronized movement of multiple heads ensures perfect alignment and uniform depth across all holes — every single time.

Furthermore, the thermal control systems keep the drill temperature stable, preventing workpiece deformation. The outcome? Clean, burr-free holes, consistent finishes, and a longer-lasting toolset.

Real-World Industrial Applications

The demand for multi spindle CNC drilling machines has expanded across diverse industries, each benefiting from the technology’s unique capabilities:

Automotive Manufacturing: For drilling multiple mounting holes on chassis, brake systems, and engine components.

Aerospace Components: For lightweight alloy and stainless steel structures requiring high precision.

Furniture & Display Systems: For drilling symmetrical holes in metal frames and fixtures.

Hydraulic & Pneumatic Equipment: For drilling ports and channels in valve blocks.

Fitness Equipment Fabrication: For simultaneous drilling of stainless steel tubes and plates used in gym frames.

No matter the industry, CNC drilling machine manufacturers continue to push forward with smarter, faster, and more durable systems.

The Manufacturing Excellence Behind DUOMI CNC

Among the global players, DUOMI CNC has positioned itself as a trusted CNC drilling machine manufacturer known for its engineering precision and reliability.

Every multi spindle CNC drilling machine from DUOMI is built on three core principles:

Durability: Heavy-duty cast iron bases ensure zero vibration, even at maximum RPM.

Intelligence: CNC control systems optimize feed speed, torque, and cutting depth in real time.

Customization: Machines are tailored to customer-specific materials, hole patterns, and productivity needs.

DUOMI’s machines are widely used in China and exported globally — from Southeast Asia to Europe — serving industries that demand uncompromising quality in metal drilling.

Performance in Numbers

DUOMI CNC’s multi spindle CNC drilling machine delivers measurable results that go beyond marketing claims:

Spindle Speed: Up to 12,000 RPM

Simultaneous Drilling: Up to 6 holes

Tool Life Increase: +250% compared to conventional machines

Cycle Time Reduction: 40–70% faster

Precision: ±0.01 mm repeatability

These numbers translate into massive productivity gains and reduced operational costs for metal fabricators.

How Multi Spindle CNC Drilling Machines Support Smart Factories

The rise of Industry 4.0 has made automation and data integration essential.

Modern CNC drilling machines are now equipped with IoT-enabled controllers that track performance, monitor tool wear, and even predict maintenance requirements.

Manufacturers like DUOMI integrate smart dashboards that provide real-time analytics, empowering factory managers to make data-driven decisions. This connectivity ensures maximum uptime, minimum waste, and consistent output quality.

What Customers Are Saying

“We drill thousands of holes in stainless steel every day. DUOMI’s multi spindle CNC drilling machine changed everything — no more broken drill bits, no more downtime. The precision is flawless.”

— Mr. Zhang, Automotive Parts Supplier

“Our productivity increased by nearly 60% after switching to DUOMI CNC. The ability to drill multiple holes simultaneously saves both labor and tool costs.”

— Ms. Lee, Fitness Equipment Manufacturer

These testimonials reflect the machine’s reliability and the manufacturer’s commitment to customer success.

Choosing the Right CNC Drilling Machine Manufacturer

When selecting a CNC drilling machine manufacturer, consider the following factors:

Experience and Expertise in multi-spindle technology

Customization Capability for your specific material and part type

After-Sales Service and Global Support

Availability of Spare Parts and Tooling Compatibility

Proven Case Studies in your industry

Manufacturers like DUOMI CNC not only deliver high-performance machines but also provide comprehensive support — from installation and training to long-term maintenance.

Conclusion: The Future of Efficient Drilling

As manufacturing evolves, efficiency and durability remain top priorities. The multi spindle CNC drilling machine represents the future — merging automation, precision, and power in one intelligent system.

For factories working with stainless steel, these machines deliver the perfect balance of speed, accuracy, and tool longevity. No more broken bits. No more wasted time. Just smooth, consistent production, hour after hour.

And behind this success are innovative CNC drilling machine manufacturers like DUOMI CNC, who continue to redefine what’s possible in industrial drilling.

If you’re ready to upgrade your production line, the solution is clear:

Invest in a multi spindle CNC drilling machine — and let precision and productivity work together for your success.