High Speed CNC Drilling Machine for Aluminum: The Ultimate Solution for Precision and Speed

In today's competitive metalworking industry, the demand for high-speed CNC drilling machines has never been higher—especially when it comes to machining aluminum parts. Aluminum's lightweight, corrosion-resistant, and conductive properties make it one of the most commonly used materials in modern manufacturing. Yet, drilling aluminum efficiently without tool breakage remains a major challenge for many factories.

High Speed CNC Drilling Machine for Aluminum

This is where the new generation of CNC drilling machines for aluminum stands out — offering not only faster drilling speeds but also unmatched tool stability, longer drill life, and superior hole accuracy.

Why Aluminum Drilling Requires Precision Engineering

At first glance, aluminum may seem easier to machine than stainless steel. However, its soft and sticky nature causes chips to adhere to the drill, leading to clogging, friction, and ultimately drill bit breakage.

Conventional drilling machines often fail in maintaining stability and precision at high RPMs. Overheating, poor lubrication, and chip accumulation reduce efficiency and increase tool costs.

Modern CNC drilling machines solve these issues with intelligent feed control, advanced spindle design, and integrated cooling systems — ensuring smooth chip evacuation and extended tool life.

With a high speed CNC drilling machine, even continuous drilling on 6061 or 7075 aluminum alloys becomes effortless, maintaining clean, burr-free holes with micron-level precision.

The Evolution of High-Speed CNC Drilling

Over the past decade, CNC drilling technology has evolved dramatically. From simple 3-axis systems to high-speed, multi-spindle, and automatic tool-changing models, manufacturers like DUOMI CNC have pushed the boundaries of drilling efficiency.

Today's high speed CNC drilling machine for aluminum combines servo-driven feed control, digital torque monitoring, and precision spindles capable of running at 10,000–15,000 RPM. This technological leap enables stable, vibration-free drilling even on thin-walled or curved aluminum components — something impossible on traditional machines.

Key improvements include:

Dynamic Spindle Balancing: Minimizes vibration at ultra-high speeds.

Smart Lubrication Systems: Prevents chip adhesion and overheating.

Rigid Machine Frames: Absorb torque and maintain micron-level accuracy.

Automated Tool Calibration: Ensures consistent depth and precision.

AI Feed Optimization: Adjusts drilling parameters in real time.

These features make the CNC drilling machine for aluminum an indispensable tool for aerospace, automotive, and industrial component manufacturers.

High-Speed Drilling Without Tool Breakage — The Game Changer

Drill bit breakage used to be one of the biggest problems in aluminum drilling operations. It not only wastes time but also damages parts, halts production, and increases maintenance costs.

The new generation of CNC drilling machines eliminates this issue completely.

Here's how:

Automatic Feed Adjustment

The machine monitors torque resistance and adjusts feed speed accordingly. This prevents overpressure and ensures consistent cutting force even during long production cycles.

Cooling and Chip Evacuation Design

High-speed coolant flow is directed right into the cutting zone, flushing chips away instantly. It keeps the tool cool, prevents clogging, and extends drill lifespan.

Advanced Spindle Motor Control

Spindle rotation and feed motion are synchronized to maintain constant chip load — the key to avoiding micro-cracks and tool breakage.

Precision Alignment and Clamping

Aluminum parts are fixed with hydraulic or pneumatic clamping systems, ensuring zero vibration even under 15,000 RPM spindle speeds.

With these systems in place, the high speed CNC drilling machine for aluminum not only reduces tool consumption but also improves throughput by up to 40%.

Applications Across Modern Industries

Aluminum is the backbone of countless industries — and so are CNC drilling machines. Whether you're manufacturing automotive components, aerospace parts, or heat sinks, precision holes are essential.

Here are a few key applications where CNC drilling machines for aluminum make a difference:

Aerospace Components: Lightweight yet high-strength aluminum alloys require flawless holes for riveting and assembly.

Automotive Parts: Precision drilling for cylinder heads, brackets, and electric vehicle housings.

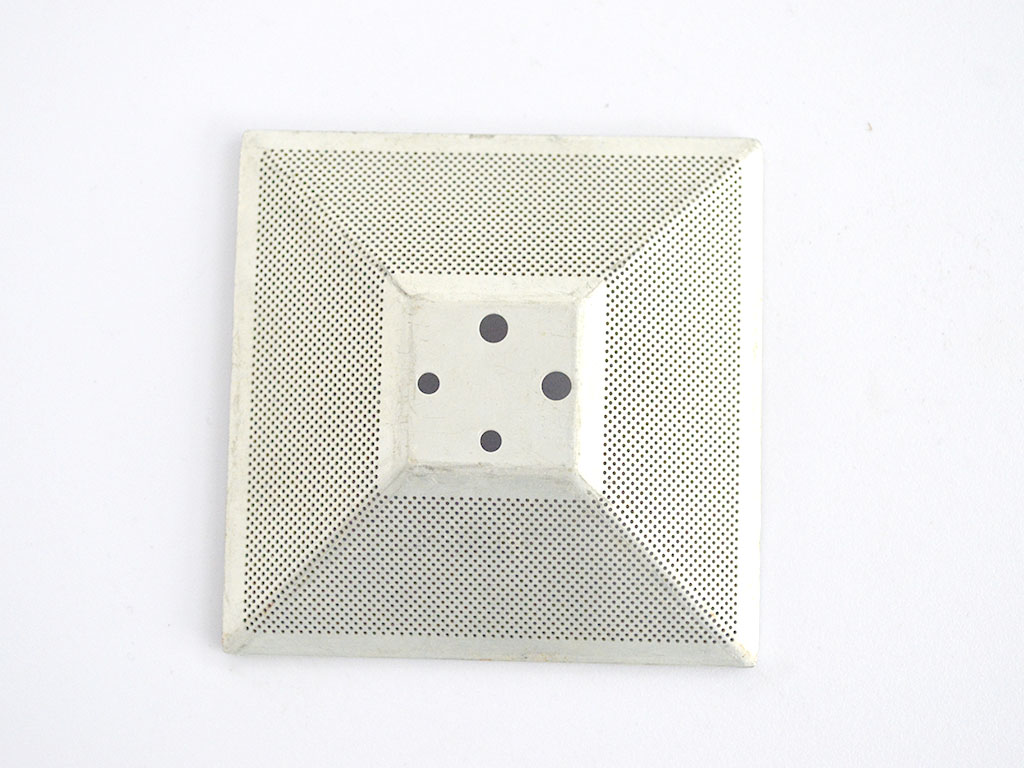

Electronics & Cooling Systems: Clean, consistent holes for liquid-cooling plates and heat exchangers.

Furniture & Architecture: High-speed drilling of extruded aluminum profiles used in modular systems.

Solar and Energy Equipment: Accurate hole positioning for mounting and connection structures.

No matter the industry, DUOMI CNC's high speed CNC drilling machine guarantees repeatable accuracy, minimal burrs, and zero tool breakage — even in 24/7 production environments.

Performance That Speaks in Numbers

A typical DUOMI CNC drilling machine can deliver:

Spindle Speed: Up to 60,000 RPM

Feed Rate: Up to 200 mm/min

Hole Tolerance: ±0.01 mm

Cycle Time Reduction: Up to 35%

Tool Life Increase: Up to 300% longer

These statistics aren't just numbers — they represent real-world production advantages that translate into profit, reliability, and quality assurance for your operation.

Energy Efficiency and Environmental Impact

Sustainability is no longer optional. Modern factories demand energy-efficient solutions without compromising performance.

DUOMI's CNC drilling machines for aluminum are built with servo systems that reduce idle power consumption and intelligent standby modes that minimize energy use when the machine is not cutting. Moreover, the dry-drilling or minimum-lubrication options reduce coolant waste, making it both eco-friendly and cost-effective.

Real Workshop Benefits

Manufacturers using DUOMI CNC drilling machines report significant improvements in both productivity and product quality.

One aluminum component manufacturer shared:

“Before switching to DUOMI's high speed CNC drilling machine, we replaced broken drill bits every two hours. Now, a single tool lasts for days, and we've reduced downtime by 50%. The machine's stability and precision are unmatched.”

Another client in the automotive sector added:

“We used to struggle with chip clogging when drilling 7075 aluminum parts. DUOMI's machine solved it completely. The chip evacuation and cooling system are next-level.”

Why Choose DUOMI CNC?

DUOMI CNC has spent over a decade perfecting precision drilling systems for metal industries.

Here's why manufacturers worldwide trust DUOMI:

Customizable Solutions: Tailored drilling machines for different aluminum profiles and thicknesses.

Stable Core Design: Heavy-duty cast iron base ensures zero vibration.

Smart Automation: Options for multi-spindle heads and robotic loading systems.

Global Support: Service centers and engineers across Asia, Europe, and the Americas.

Proven Quality: Every CNC drilling machine undergoes strict calibration and real-material testing before shipment.

When you invest in a high speed CNC drilling machine from DUOMI, you're investing in reliability, innovation, and performance.

Conclusion: The Future of Aluminum Drilling is Here

The shift toward lightweight and high-strength materials has made aluminum an irreplaceable component in global manufacturing. To meet modern production demands — speed, precision, and durability — investing in a CNC drilling machine for aluminum is not just an upgrade; it's a necessity.

With the right high speed CNC drilling machine, you can achieve:

Faster production cycles

Longer tool life

Superior accuracy

Zero downtime

DUOMI CNC is proud to lead this evolution, delivering machines that redefine what's possible in aluminum drilling.

Whether you're machining heat sinks, automotive parts, or aerospace components, DUOMI's CNC drilling machines will help your business stay ahead — faster, sharper, and smarter.