CNC Drilling Machine for Stainless Steel Parts: The Ultimate Solution for Precision and Durability

1. Introduction: The Challenge of Drilling Stainless Steel

Drilling stainless steel has always been a tough task for manufacturers. The material's high hardness, heat resistance, and tendency to cause tool wear make it one of the most difficult metals to process efficiently.

Traditional drilling machines often face problems such as broken drill bits, poor surface finish, and slow feed rates.

That's where the CNC drilling machine for stainless steel parts comes in — a revolutionary tool designed to deliver precision, stability, and reliability in one integrated system.

With advanced cooling control, optimized spindle torque, and intelligent feed algorithms, modern CNC drilling machines are transforming the way stainless steel is machined across industries like automotive, aerospace, medical devices, and industrial components.

CNC Drilling Machine for Stainless Steel Parts

2. Why Stainless Steel Is Hard to Drill

Before exploring the machine's benefits, it's crucial to understand why stainless steel causes so many challenges:

High strength and toughness: It resists deformation, which puts extreme pressure on drill bits.

Low thermal conductivity: Heat builds up quickly, leading to tool wear and even drill tip fusion.

Work-hardening behavior: Once drilling starts, the metal surface hardens rapidly, making further penetration difficult.

For years, manufacturers relied on conventional machines with flood coolant and frequent tool replacement — but this only led to high costs and low consistency.

The CNC drilling machine for stainless steel parts eliminates these issues with precision engineering and intelligent automation.

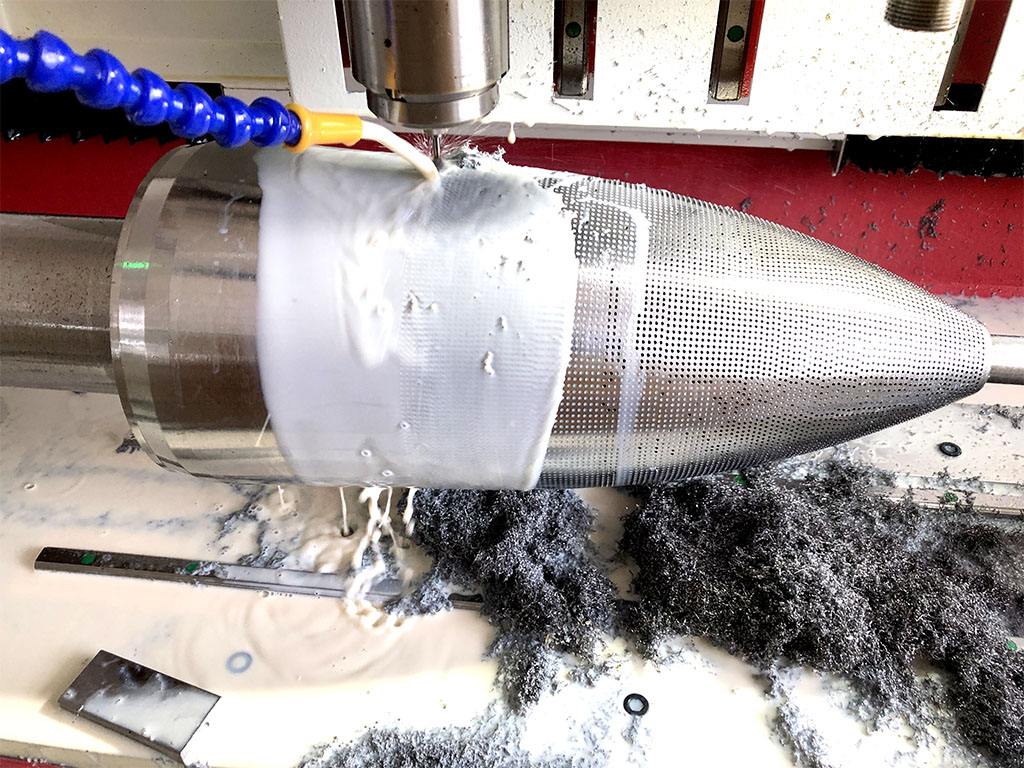

3. Advanced CNC Drilling Technology: No More Broken Drill Bits

One of the biggest breakthroughs in CNC technology is the anti-breakage drilling system.

DUOMI CNC, for instance, integrates adaptive feed control, thermal friction compensation, and smart torque balancing into their drilling platforms.

These technologies ensure that:

The spindle speed automatically adjusts based on material feedback.

Tool pressure is distributed evenly, reducing stress on the drill bit.

Cooling lubrication is optimized at micro-levels to prevent overheating.

CNC drilling machine

The result?

Even after thousands of drilling cycles, there's minimal drill wear and virtually zero tool breakage — something that's nearly impossible with traditional manual or semi-automatic drilling.

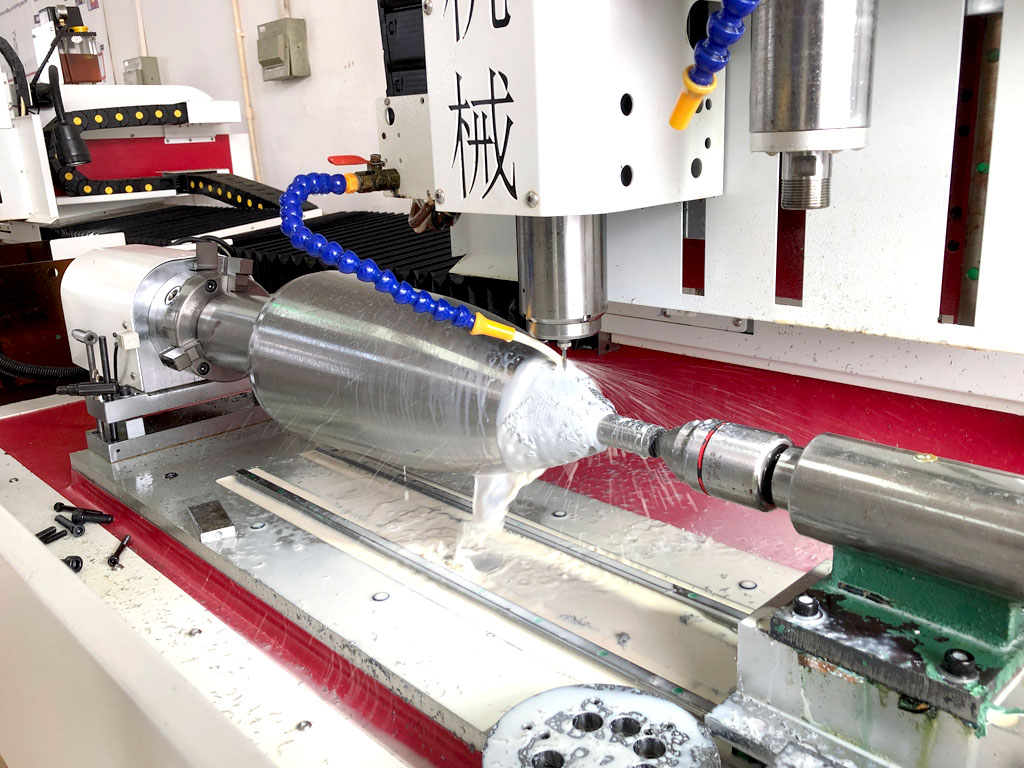

4. Precision and Efficiency Combined

A CNC drilling machine for stainless steel parts doesn't just prevent tool breakage — it also enhances overall machining precision.

Thanks to digital control and servo-driven accuracy, holes can be drilled with micron-level tolerance. The machine's intelligent software can handle complex hole patterns, multiple depths, and varying diameters with ease.

Key precision benefits include:

±0.01mm positioning accuracy

Perfect hole concentricity

Smooth surface finish, reducing post-processing

Repeatable results for mass production

Whether you're producing medical-grade stainless components or industrial pipe fittings, this precision leads directly to higher product quality and fewer rejects.

5. Intelligent Cooling for Heat Control

Heat management is the secret weapon of any CNC drilling machine for stainless steel parts.

Instead of relying on excessive coolant, the machine uses intelligent liquid cooling channels and air-mist lubrication systems.

These cooling methods maintain optimal temperature during drilling, ensuring:

Lower tool wear

Higher cutting speed

Reduced chip adhesion

Extended spindle life

By preventing thermal deformation, this technology guarantees consistent hole geometry — even during long production runs.

6. Enhanced Durability for Long-Term Operation

Modern CNC drilling machines are designed with rigid cast-iron bases, high-precision linear guides, and servo-driven spindles.

This solid foundation minimizes vibration, ensuring both stability and durability during continuous heavy-duty drilling.

For stainless steel production lines, this means 24/7 performance without the risk of misalignment or precision loss.

In addition, most high-end CNC systems come with automated lubrication, self-diagnostic alerts, and predictive maintenance functions, ensuring that downtime stays close to zero.

7. User-Friendly Control and Automation

Even with its complex capabilities, the CNC drilling machine for stainless steel parts is easy to operate.

Touchscreen interfaces, pre-set machining libraries, and automatic cycle programs make setup simple even for non-experts.

Automation features include:

Automatic tool change (ATC) for multi-diameter drilling

Position memory for repeat jobs

Remote monitoring through network connectivity

This user-centric design not only saves labor but also enhances productivity across every shift.

8. Real-World Applications

CNC drilling for stainless steel is now a standard requirement across industries that value both strength and precision.

Below are a few application examples:

Industry Application Benefit

Automotive Exhaust manifolds, flanges, engine brackets Faster drilling, fewer broken bits

Aerospace Fuel line fittings, structural joints Ultra-precise holes, heat-resistant machining

Medical Devices Surgical tools, implant parts Burr-free, smooth finishes

HVAC & Energy Cooling tubes, liquid manifolds Improved flow paths, leak-proof joints

Furniture / Construction Stainless fixtures, brackets Stronger connections without welding

These examples demonstrate how the CNC drilling machine for stainless steel parts has become an essential tool for modern manufacturing environments.

9. Cost Savings and ROI Advantages

While CNC machines may seem like a large investment, their return on investment (ROI) is rapid — especially when machining stainless steel.

You save money in multiple ways:

Fewer broken drill bits → lower tooling costs

Shorter machining cycles → higher throughput

Less rework → improved yield rates

Automation → reduced labor cost

Over a year, manufacturers report production cost reductions of 20–40%, proving that the right CNC solution pays for itself faster than expected.

10. Why Choose DUOMI CNC for Stainless Steel Drilling

DUOMI CNC has specialized in high-performance CNC drilling and tapping machines for over a decade.

Their models are built precisely for challenging metals like stainless steel, aluminum, and carbon steel.

DUOMI CNC Advantages:

Proprietary anti-breakage drill technology

Thermal friction optimization for smoother penetration

Multi-axis synchronization for complex parts

Stable operation even under high loads

From single-spindle precision models to multi-spindle CNC drilling machines for stainless steel parts, DUOMI delivers reliability, consistency, and cutting-edge automation that global manufacturers trust.

11. Future Trends: Smart Drilling and Digital Integration

As Industry 4.0 evolves, CNC drilling machines are integrating with IoT platforms, AI-driven predictive maintenance, and digital twins for process optimization.

In the near future, smart drilling systems will automatically analyze material hardness, temperature, and vibration data — optimizing feed rate in real-time for perfect stainless steel drilling without human intervention.

12. Conclusion

The CNC drilling machine for stainless steel parts has redefined modern manufacturing.

With innovations in tool protection, cooling efficiency, and automation, it allows companies to overcome the toughest material challenges with confidence.

No more broken drill bits.

No more wasted production time.

Just consistent, high-speed, high-precision drilling that delivers results every time.

If your business demands durability, precision, and long-term reliability, it's time to switch to the next generation of CNC technology — and let DUOMI CNC help you achieve unmatched performance on every stainless steel part you make.