CNC drilling tiny holes in metal is a specialized machining process that requires extreme precision, stability, and high-performance tooling. Whether you're working with stainless steel, brass, aluminum, or alloyed metals, creating accurate micro-holes—often under 1mm in diameter—demands advanced CNC technology. DUOMI CNC, a leading manufacturer of CNC drilling equipment in China, offers state-of-the-art solutions engineered specifically for micro-hole applications in metal components.

Why Tiny Hole Drilling Requires CNC Precision?

Drilling tiny holes in metal materials is far more than a scaled-down version of conventional drilling. It presents a unique set of technical challenges:

Tool Breakage Risk: Micro tools are fragile and can snap easily if spindle speed and feed rate are not perfectly tuned.

Material Hardness: Metals like stainless steel and copper alloys pose high resistance, requiring robust machines and carbide tooling.

Thermal Control: Heat buildup can distort holes and wear out tools prematurely.

Chip Evacuation: Tiny holes don't allow easy chip removal, increasing the risk of clogging.

To address these issues effectively, a purpose-built CNC drilling machine is essential.

DUOMI CNC: Your Micro-Hole Machining Specialist

At DUOMI CNC, we specialize in CNC drilling machines designed to handle even the smallest holes with unmatched precision and repeatability. Our solutions are ideal for industries such as electronics, aerospace, automotive, furniture, medical devices, and metal fabrication, where CNC drilling of tiny holes in metal is a daily requirement.

Core Advantages of DUOMI CNC Machines:

High-RPM Spindles: Our CNC machines come with spindle speeds up to 20,000 RPM, ideal for micro-diameter drills.

Precision Linear Guides & Ball Screws: Ensure micron-level positioning and repeatability.

Advanced Cooling Systems: Integrated mist or oil-based lubrication prevents overheating and maintains tool life.

Multi-Spindle Customization: For high-volume operations, DUOMI offers synchronized multi-spindle heads to drill multiple micro-holes simultaneously.

Touchscreen Interface: Simple programming and real-time adjustments for variable hole sizes and materials.

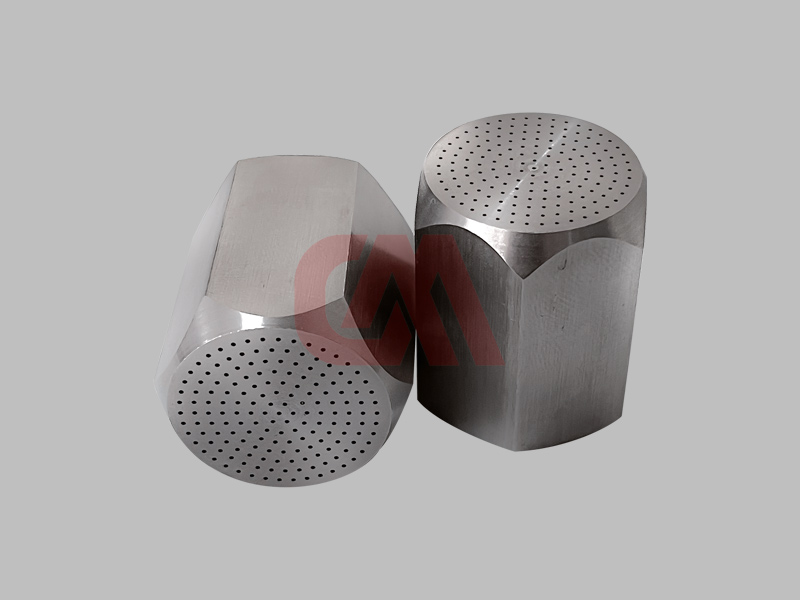

CNC small-hole drilling in stainless steel faucets and showerheads

Real Applications: Where Tiny Hole CNC Drilling Matters

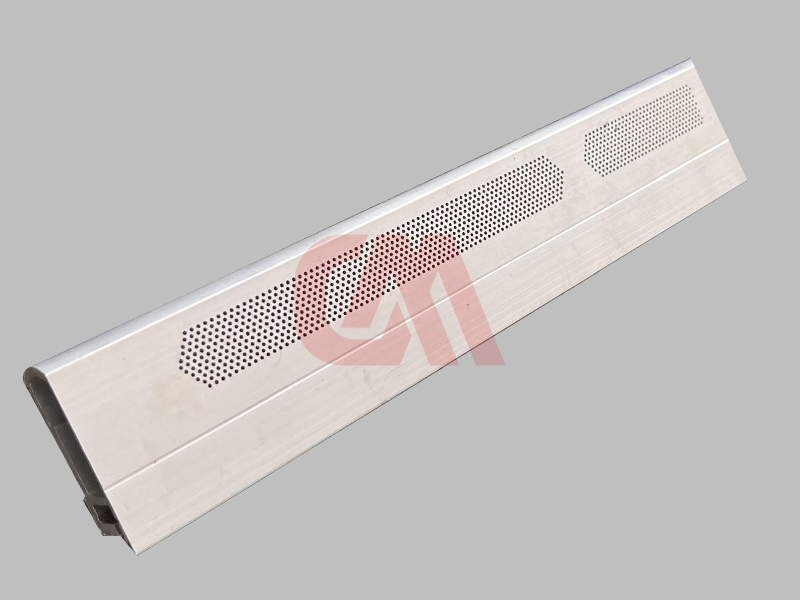

CNC drilling tiny holes in metal is indispensable in the following applications:

Heat exchangers and radiators

Precision medical components and surgical tools

Electronic connectors and PCB heat sinks

Fuel injectors and engine parts

Custom brass and aluminum furniture fittings

Whether it's drilling a 0.5mm hole 5mm deep in brass tubing, or fabricating hundreds of micro-apertures in stainless steel sheets, DUOMI CNC ensures consistency and speed every time.

Case Study: Precision Meets Productivity

A Southeast Asian client manufacturing electric scooter components needed to drill hundreds of 0.6mm holes in aluminum brackets. Their manual process led to tool breakage and inconsistent quality. After implementing a DUOMI CNC micro-drilling system, they achieved:

300% increase in productivity

Over 95% reduction in rework rate

Perfect roundness and depth control across all parts

This proves how vital CNC precision is when drilling tiny holes in metal—especially at scale.

CNC drilling for small holes in aluminum alloy

Why Choose DUOMI CNC?

With over 15 years of industry experience, DUOMI CNC has become a trusted partner to manufacturers around the world. Our machines are designed to handle real-world production challenges—from ultra-thin tubing to multi-layer plates, from non-ferrous metals to hardened steel.

Key Features at a Glance:

✔ CNC control systems for dynamic toolpaths

✔ Custom jigs and fixtures for non-standard parts

✔ 24/7 customer support and remote diagnostics

✔ Global shipping and technical assistance

Looking to improve the way you drill tiny holes in metal components? DUOMI CNC offers turnkey solutions tailored to your production line and material requirements.

Contact us for a free consultation or machine recommendation.

Visit our website: www.xdmcnc.com

Email: [email protected]