Precision and Efficiency: Drilling Small Holes in Brass with DUOMI CNC Solutions

Introduction

Drilling small holes in brass is a critical task across numerous industries, including electronics, plumbing, automotive, and custom fabrication. Brass is a soft yet sturdy metal, making it both machinable and prone to deformation if not handled correctly. Precision, tool selection, and machine stability are essential for achieving clean, burr-free results—especially when hole diameters are less than 3mm. That's where DUOMI CNC steps in, providing high-performance CNC drilling solutions tailored for small-hole processing in brass and other non-ferrous metals.

Why Brass Demands Special Attention in Small-Hole Drilling

Brass has excellent machinability due to its low melting point and smooth surface, but drilling small holes presents unique challenges:

Chip Evacuation: Micro-holes generate fine chips that must be evacuated efficiently to avoid clogging or tool breakage.

Heat Management: Excessive heat can deform the hole or cause tool wear.

Tool Deflection: Without sufficient machine rigidity, tool deflection leads to off-center or tapered holes.

To overcome these difficulties, manufacturers need advanced CNC machinery designed with precision control, tool cooling, and adaptive speed settings.

DUOMI CNC: Your Trusted Partner for Brass Micro-Drilling

As a leading Chinese CNC drilling machine manufacturer, DUOMI CNC specializes in machines engineered for high-precision drilling, tapping, and thermal friction processing. Our solutions are widely used in furniture hardware, fitness equipment, automobile components, and more—especially for drilling small holes in brass, copper, and aluminum tubes and plates.

Key Advantages of DUOMI CNC Machines:

Micron-Level Accuracy: DUOMI's machines are equipped with high-resolution servo systems and ball screws to guarantee precise hole positioning and depth control.

Custom Spindle Options: Whether you need high-RPM spindles for ultra-fine holes or multi-head configurations for increased productivity, DUOMI has a solution.

Thermal Management Systems: Our CNCs come with integrated mist cooling or water-based lubrication to manage heat and extend tool life.

User-Friendly Interface: Touchscreen controls and intuitive programming interfaces make it easy for operators to set drilling parameters for various brass components.

Drilling small holes 0.5mm in diameter and 5mm deep in brass

Applications of Small Hole Drilling in Brass

Electrical Terminals and Connectors

Custom Brass Components for Furniture

Automotive Sensors and Fittings

Instrument Panels and Gauge Mountings

Precision Plumbing Fixtures

With the rising demand for lightweight, corrosion-resistant parts, brass continues to be a preferred material—and DUOMI CNC's drilling machines make it possible to process this metal with speed and reliability.

Real-World Case: A Client in Europe Improves Production by 40%

One of our European clients, a manufacturer of high-end bathroom fixtures, recently upgraded to DUOMI CNC's multi-spindle drilling machine. Their previous manual method resulted in high rejection rates and slow production. After the switch, they reported:

40% increase in throughput;

90% reduction in rework due to off-center holes;

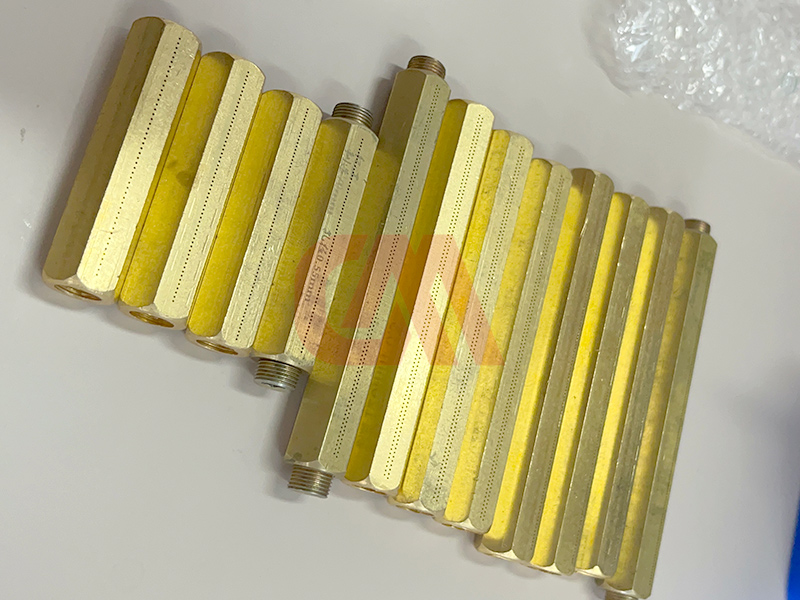

Consistent performance on brass pipes from 10mm to 40mm diameter;

This is a testament to the importance of using purpose-built equipment for drilling small holes in brass—especially in high-volume operations.

CNC drilling small holes in copper caps

Optimize Your Brass Processing Today

If you're in the business of small-hole drilling in brass, don't compromise on quality. With DUOMI CNC, you gain access to machines that are engineered for precision, built for durability, and backed by a team of professionals with years of industry experience.

Contact us today to schedule a free consultation or request a live demo of our CNC drilling solutions for brass components.

Visit: www.xdmcnc.com