Introduction: Why Tube Drilling Still Frustrates Manufacturers

If you've ever worked with steel, aluminum, or stainless tubes, you already know drilling them is not as simple as it looks. Traditional drilling methods often end up wasting time, producing inconsistent holes, or even damaging the tube walls. The result? Delays, rework, and frustrated customers.

That's exactly why more companies are turning to a CNC tube drilling machine. With advanced automation and precision engineering, these machines are changing the way industries handle tube fabrication. And at DUOMI CNC, we've seen firsthand how manufacturers worldwide are cutting costs, saving time, and boosting productivity by making the switch.

The Pain Points of Traditional Tube Drilling

Before we get into solutions, let's call out the struggles most fabricators deal with when they stick to outdated drilling methods:

Inconsistent hole quality – Manual drilling often leaves burrs or misaligned holes.

High labor costs – Skilled workers are expensive, and fatigue leads to errors.

Slow production – Conventional drilling setups can't keep up with today's high-volume demands.

Tube damage – Thin-walled or delicate materials are easily deformed with old equipment.

Sound familiar? If yes, then it's time to think seriously about CNC tube drilling.

Why a CNC Tube Drilling Machine is the Smarter Choice

Unlike old-fashioned drilling setups, a CNC tube drilling machine offers automation, speed, and precision all in one package.

Higher productivity – Multiple holes drilled in one setup, without repositioning.

Pinpoint accuracy – Perfect hole placement every single time.

Less waste – Reduce scrap by eliminating errors and rework.

Versatility – Works on square, round, and rectangular tubes of different materials.

With CNC, you don’t just drill holes—you streamline your entire production process.

DUOMI CNC: Redefining Tube Drilling for Global Manufacturers

At DUOMI CNC, we've built our reputation on designing machines that solve real-world manufacturing problems. Our CNC tube drilling machines are trusted in industries like:

Furniture manufacturing – Precise drilling for display racks, tables, and chairs.

Fitness equipment – Strong, repeatable holes for gym machines and frames.

Automotive parts – Reliable drilling for exhaust systems, chassis tubes, and brackets.

Construction and infrastructure – Heavy-duty drilling for steel framework and structural tubing.

Our clients consistently report 30–50% faster production cycles after upgrading to DUOMI CNC.

Key Features of DUOMI CNC Tube Drilling Machines

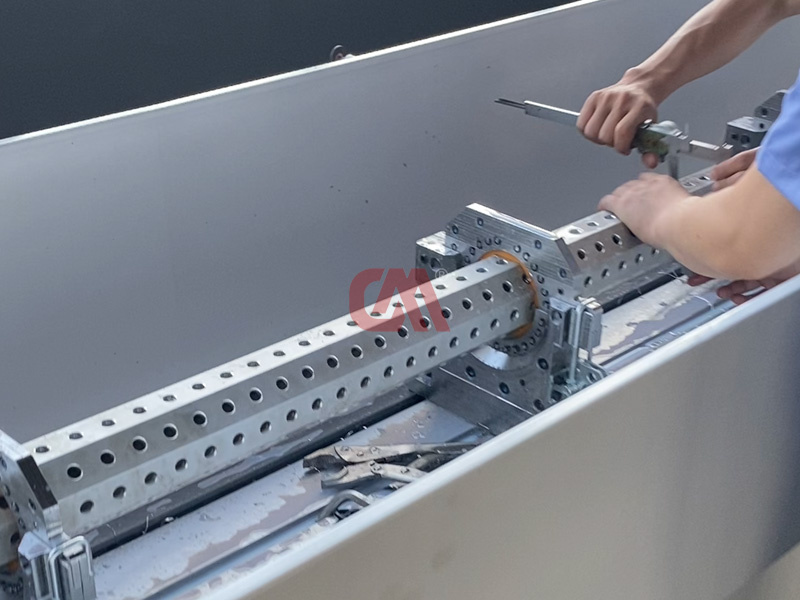

CNC Tube Drilling Machine Built for Performance

Rigid machine frames and high-speed spindles ensure stability and precision, even when drilling large or thick tubes.

Easy-to-Use CNC Controls

Forget complicated programming. The intuitive interface allows operators to quickly set parameters and get production running in no time.

Multi-Process Capabilities

Our machines can drill, tap, and chamfer in a single setup. That means less handling, faster output, and fewer secondary operations.

Traditional Drilling vs. CNC Tube Drilling

| Feature | Traditional Drilling | CNC Tube Drilling Machine |

|---|---|---|

| Speed | Slow, one hole at a time | High-speed, multiple holes |

| Accuracy | Prone to human error | Consistent and precise |

| Labor requirement | High, constant supervision | Low, one operator runs multiple machines |

| Material handling | Risk of tube deformation | Stable clamping system |

The comparison is clear: CNC is not just faster, it's smarter.

Real Success Stories

A client in the furniture industry used to spend hours drilling holes for steel tube display racks. After investing in a DUOMI CNC tube drilling machine, they cut production time by half while improving hole alignment.

Another customer in automotive parts manufacturing faced constant rework due to misaligned holes in exhaust tubing. With DUOMI CNC, their rejection rate dropped by over 80%, saving thousands in annual costs.

Shipping, Delivery, and Worry-Free Warranty

When you choose DUOMI CNC, you're not just buying a machine—you're buying peace of mind.

Flexible shipping options – We ship from major Chinese ports including Shanghai, Shenzhen, Qingdao, and Guangzhou, or any port specified by the customer.

Fast delivery – Machines are dispatched quickly to keep your production on track.

Worry-free warranty – Every machine comes with full warranty coverage, so you can focus on production without stress.

Our goal is simple: deliver your machine safely, quickly, and backed with reliable after-sales service.

The Future of CNC Tube Drilling

As industries move toward automation and Industry 4.0, CNC tube drilling will only become more essential. The demand for lightweight materials, complex designs, and faster turnaround times means companies that upgrade now will be better prepared for the future.

Emerging trends include:

Integration with smart factories – Linking CNC machines with ERP systems for real-time monitoring.

Eco-friendly manufacturing – Reducing energy waste and improving tool life.

Customization – Flexible CNC solutions to handle different shapes and customer-specific projects.

Conclusion: Don't Get Left Behind

Sticking with traditional drilling methods is no longer sustainable. If you want to stay competitive, it's time to consider a CNC tube drilling machine. With DUOMI CNC, you get precision, speed, and dependability—all backed by fast global shipping and a no-worry warranty.

From Shanghai to Shenzhen, Qingdao to Guangzhou, we deliver directly to the port of your choice, ensuring your production never skips a beat.

Now is the time to upgrade. With DUOMI CNC, you're not just buying a machine—you're investing in your future.