Why Steel Plate Drilling Still Matters

If you're in industries like construction, shipbuilding, or heavy equipment manufacturing, you know steel plate drilling is not just another process—it's the backbone of your production line. The problem? Traditional drilling methods are painfully slow, prone to errors, and costly in the long run. That's where a steel plate drilling machine steps in.

At DUOMI CNC, we've been working with global manufacturers who faced the same challenges—manual drilling taking too long, inconsistent hole quality, and frequent downtime. After switching to our advanced CNC technology, they discovered not just faster production but a new standard of accuracy and profitability.

The Pain Points of Traditional Steel Plate Drilling

Before diving into the solutions, let's face the issues most companies struggle with:

Inconsistent quality – Manual drilling often leaves burrs, uneven depths, or misaligned holes.

Labor-intensive – Skilled workers are hard to find, and labor costs keep climbing.

Low efficiency – Conventional drilling can take hours for tasks that modern CNC machines finish in minutes.

Frequent tool wear – Traditional setups lack the precision spindle control to extend tool life.

If these sound familiar, it's time to rethink your drilling strategy.

Why Choose a CNC Steel Plate Drilling Machine?

A steel plate drilling machine equipped with CNC control changes the game by offering:

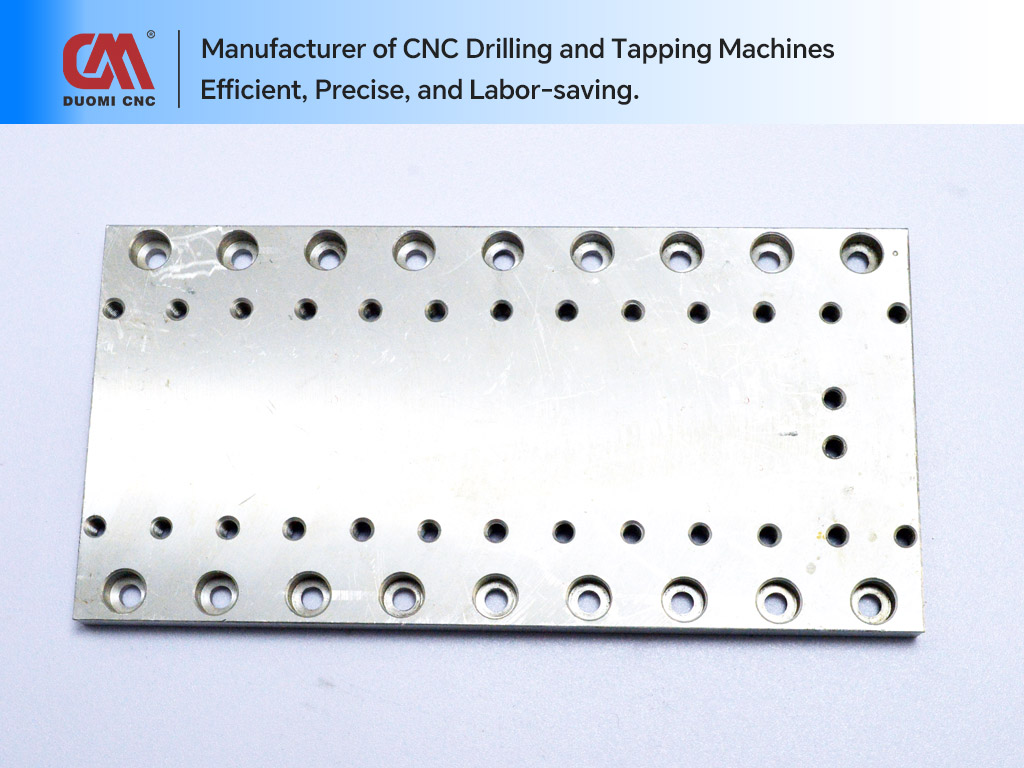

High-speed drilling – Multiple holes drilled in one setup, with perfect repeatability.

Superior accuracy – Tolerance levels that meet global industry standards.

Flexibility – Handle plates of different thicknesses and materials without retooling.

Automation – Operators can manage multiple machines at once, reducing manpower costs.

This isn't just about drilling holes. It's about transforming productivity and reducing waste.

DUOMI CNC: Setting the Standard for Steel Plate Drilling

DUOMI CNC has become a trusted name worldwide because we don't just sell machines—we deliver solutions. Our steel plate drilling machines are designed for:

Heavy-duty fabrication shops

Shipbuilding and offshore industries

Bridge and infrastructure projects

Energy and wind power manufacturing

Clients report a 30–50% increase in production efficiency after integrating DUOMI CNC systems. That means fewer bottlenecks and more finished products shipped on time.

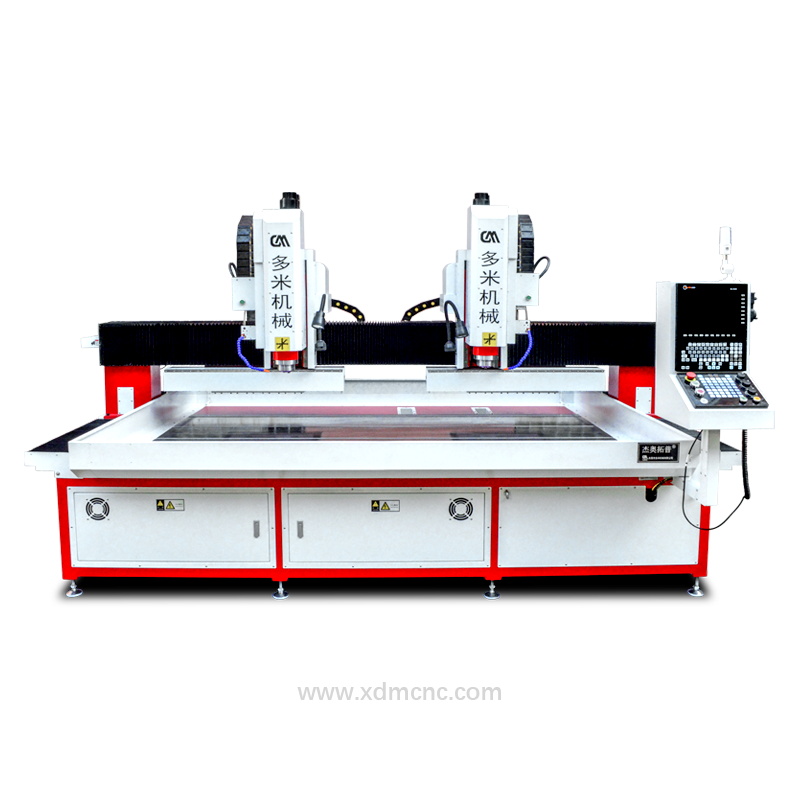

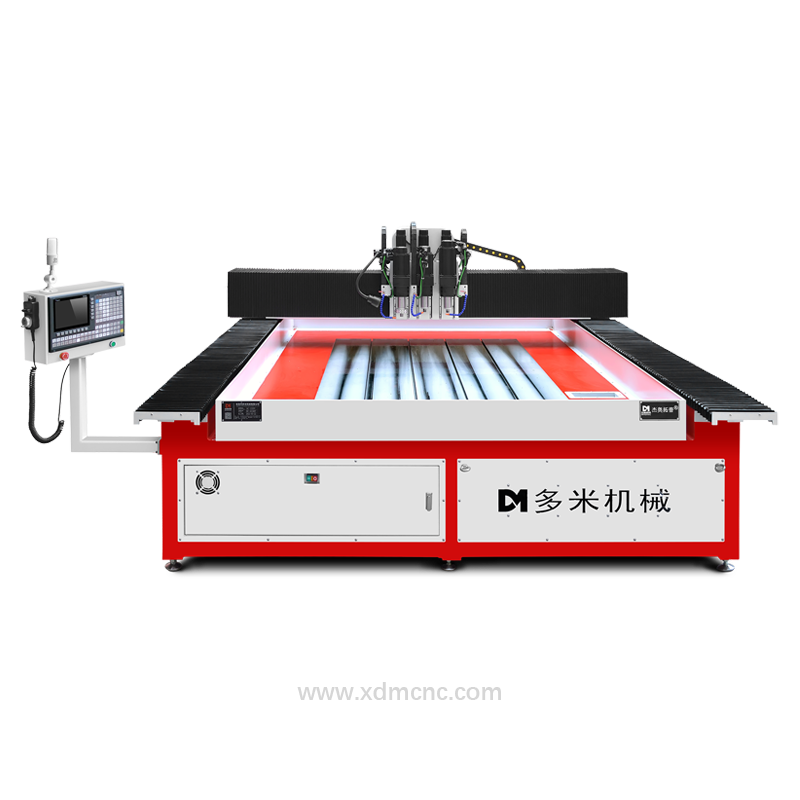

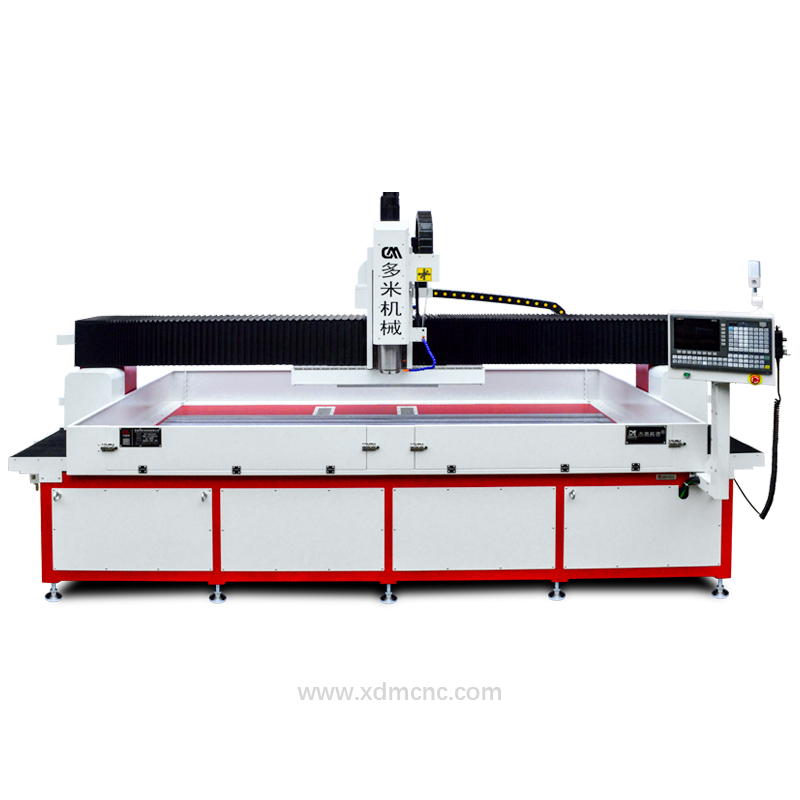

Key Features of DUOMI CNC Steel Plate Drilling Machines

Steel Plate Drilling Machine Built for Speed and Accuracy

Our machines are engineered with rigid frames, high-torque spindles, and advanced servo motors. Whether you're drilling carbon steel, stainless steel, or alloy plates, precision is never compromised.

User-Friendly CNC Control System

The touchscreen interface is simple, intuitive, and built for real operators. No steep learning curve, no endless programming headaches. Just plug in your design and get to work.

Multi-Function Capabilities

Beyond just drilling, our machines can also handle tapping, countersinking, and chamfering—all in one setup. That means fewer secondary processes and reduced handling time.

Comparing Traditional Drilling vs. CNC Drilling

| Aspect | Traditional Drilling | CNC Steel Plate Drilling Machine |

|---|---|---|

| Speed | Slow, one hole at a time | High-speed, multiple holes |

| Accuracy | Inconsistent, human error | Micron-level precision |

| Labor | High, needs constant supervision | Low, one operator runs multiple machines |

| Cost | Rising with tool wear and labor | Reduced overall production cost |

The comparison makes it clear: CNC drilling is not an expense—it’s an investment.

Real-World Success Stories

One of our clients in the shipbuilding industry had been using traditional drills for years. Their biggest issue? Delays caused by inaccurate hole placement, which often required rework. After installing DUOMI CNC's steel plate drilling machine, their error rate dropped by over 80%. The result: faster production cycles and millions saved annually.

In another case, a construction machinery manufacturer in Southeast Asia cut their drilling time in half while doubling production volume. Their feedback? “The machine paid for itself in less than a year.”

Shipping, Delivery, and Warranty You Can Trust

When you invest in DUOMI CNC, you're not just buying a machine—you're getting a commitment.

Flexible shipping options – We ship from major Chinese ports including Shanghai, Shenzhen, Qingdao, and Guangzhou, or any port specified by the customer.

Fast delivery – Machines are dispatched quickly to minimize downtime for your business.

Worry-free warranty – Every machine comes with a comprehensive warranty, giving you peace of mind from day one.

Our global logistics network ensures that wherever you are, your machine arrives safely and on schedule.

Future of the Steel Plate Drilling Market

The global demand for CNC drilling solutions is rising. As industries adopt Industry 4.0 automation, CNC drilling machines are no longer optional—they're essential. Companies that upgrade today are better positioned to stay competitive tomorrow.

Key trends include:

Automation integration – Smart factories linking CNC drilling with ERP systems.

Sustainability – Machines designed to reduce energy consumption and material waste.

Customization – Flexible CNC systems that can adapt to customer-specific projects.

Conclusion: The Right Time to Upgrade

If you're still relying on traditional drilling methods, chances are you’re losing money, time, and market opportunities. A steel plate drilling machine from DUOMI CNC delivers unmatched speed, accuracy, and reliability that directly impacts your bottom line.

From Shanghai to Shenzhen, Qingdao to Guangzhou, and beyond—we ensure fast shipping, reliable after-sales service, and a hassle-free warranty policy tailored to your needs.

Now is the time to upgrade. With DUOMI CNC, you're not just buying a machine—you're investing in a smarter, more profitable future.