High-speed CNC drilling machines have become an essential tool in modern manufacturing industries, enabling companies to achieve exceptional precision, efficiency, and productivity. With rapid advances in computer numerical control (CNC) technology, high-speed drilling has expanded its applications across numerous sectors such as automotive, aerospace, electronics, energy, medical devices, and construction. The ability to produce accurate holes at a high feed rate while maintaining excellent surface finish makes these machines indispensable for both mass production and high-value custom components. This article explores the broad application market of high-speed CNC drilling machines, analyzing their importance, industrial adoption, and future growth potential.

Application Market of High-Speed CNC Drilling Machines

The Role of High-Speed CNC Drilling Machines in Modern Manufacturing

High-speed CNC drilling machines combine precision automation with cutting-edge spindle technology, allowing for drilling at significantly higher speeds compared to conventional methods. Their applications are driven by three major needs in modern manufacturing:

High productivity – Increased spindle speeds reduce cycle times, enabling mass production.

Dimensional accuracy – Consistency in drilling depth, hole diameter, and positioning ensures quality control.

Versatility – Ability to drill various materials including steel, aluminum, composites, plastics, and exotic alloys.

As industries move toward lightweight materials and complex product designs, the demand for high-speed drilling solutions continues to grow.

7-Meter 4-Axis CNC Pipe Drilling and Tapping Machine DNC-7003DT(R1)

Application in the Automotive Industry

The automotive sector is one of the largest markets for high-speed CNC drilling machines. Automakers increasingly rely on lightweight aluminum and composite components to improve fuel efficiency and reduce emissions. These materials require precise drilling for assembly and structural integrity.

Engine blocks and cylinder heads – High-speed drilling ensures accurate cooling passages and lubrication holes.

Chassis and frames – Precision drilling enables strong joints while minimizing material stress.

EV battery housings – Electric vehicles require specialized drilling for battery modules and cooling systems.

The transition to electric mobility further boosts demand for CNC drilling, as manufacturers need to create new components with tighter tolerances and higher volumes.

4-Axis Vertical Horizontal CNC Drilling and Tapping Machine DNC-3003DDDD(R1)

Aerospace and Defense Applications

The aerospace sector emphasizes lightweight construction, safety, and reliability. High-speed CNC drilling machines play a critical role in producing structural components and precision parts for both civil and military aircraft.

Aircraft fuselage panels – Thousands of fastener holes must be drilled with high accuracy and consistency.

Turbine engine components – Cooling holes in blades and vanes require ultra-precise micro drilling.

Composite materials – Modern aircraft use carbon fiber-reinforced plastics (CFRP) that require specialized high-speed drilling to prevent delamination.

The defense industry also relies on CNC drilling for armored vehicles, naval vessels, and missile systems, where accuracy and reliability are paramount.

CNC Gantry Drilling Machine DNC-1880D

Electronics and Semiconductor Industry

With the miniaturization of electronic devices, the electronics industry requires high-speed CNC drilling for printed circuit boards (PCBs), connectors, and semiconductor packaging.

Micro-holes in PCBs – Drilling thousands of micro vias ensures electrical connections in multilayer boards.

Heat sinks and housings – Precise drilling enables better thermal management in electronic systems.

5G components – The new generation of communication devices demands drilling of high-frequency compatible housings.

The growing global demand for smartphones, wearables, and IoT devices makes the electronics industry a rapidly expanding market for high-speed drilling.

CNC Thermal Drilling and Tapping Machine DHM-430DT

Medical Equipment and Healthcare Applications

Medical device manufacturing demands extreme precision and compliance with strict quality standards. High-speed CNC drilling machines enable the production of complex medical components.

Surgical instruments – Precision holes in stainless steel and titanium instruments enhance performance and hygiene.

Orthopedic implants – Accurate drilling ensures compatibility with human bone structures.

Dental tools – High-speed drilling is used in the production of dental burs and implants.

As healthcare technology advances, the need for custom and mass-produced medical devices further drives demand for CNC drilling solutions.

CNC Thermal Drilling and Tapping Machine DHM-2030DT

Energy and Renewable Power Sector

Energy industries, both conventional and renewable, rely heavily on CNC drilling for equipment production and maintenance.

Oil and gas – Drilling machines are used to produce components for pipelines, valves, and offshore platforms.

Wind turbines – Large structural parts require precise holes for bolting and assembly.

Solar power – Frames and mounting systems for solar panels depend on lightweight aluminum drilling.

The shift toward renewable energy sources creates new markets for high-speed CNC drilling, especially in manufacturing wind turbine hubs and solar farm infrastructure.

Construction and Infrastructure Applications

In the construction sector, CNC drilling machines are essential for producing structural steel, aluminum profiles, and prefabricated components.

Steel beams and girders – High-speed drilling improves the speed of fabricating high-rise buildings and bridges.

Aluminum curtain walls – Precision drilling ensures accurate assembly of modern architectural facades.

Prefabricated modular housing – CNC drilling supports the growing modular construction industry by producing repeatable, precise parts.

This sector benefits from both the efficiency and scalability of high-speed drilling systems.

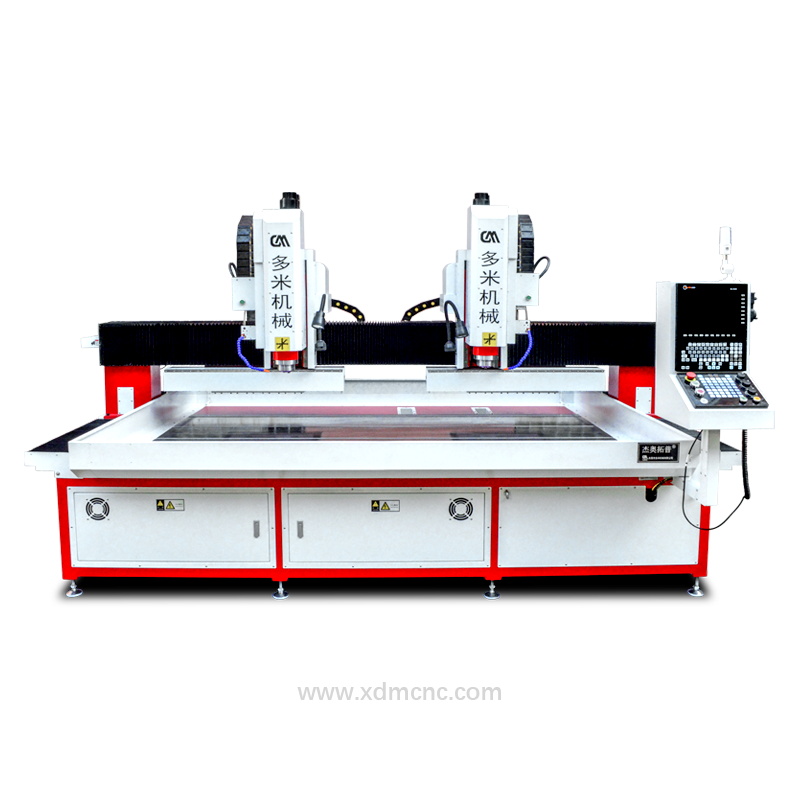

High Speed CNC Drilling Machine DNC-2030HD

Global Market Trends and Growth Potential

The global CNC drilling machine market has witnessed steady growth, with high-speed models gaining significant adoption. Several trends define its future:

Automation and Industry 4.0 – Integration of IoT sensors, data analytics, and smart controls improves efficiency.

Customization – Manufacturers increasingly seek flexible machines for both high-volume and small-batch production.

Sustainability – Energy-efficient drilling solutions align with global carbon reduction goals.

Emerging economies – Rapid industrialization in Asia-Pacific, Latin America, and Africa increases market demand.

According to industry forecasts, the global CNC drilling machine market is expected to grow at a CAGR of over 5% in the next decade, with high-speed machines contributing significantly to this growth.

Challenges and Future Outlook

While the application market is expanding, challenges remain:

High initial investment – Advanced CNC drilling machines require significant capital.

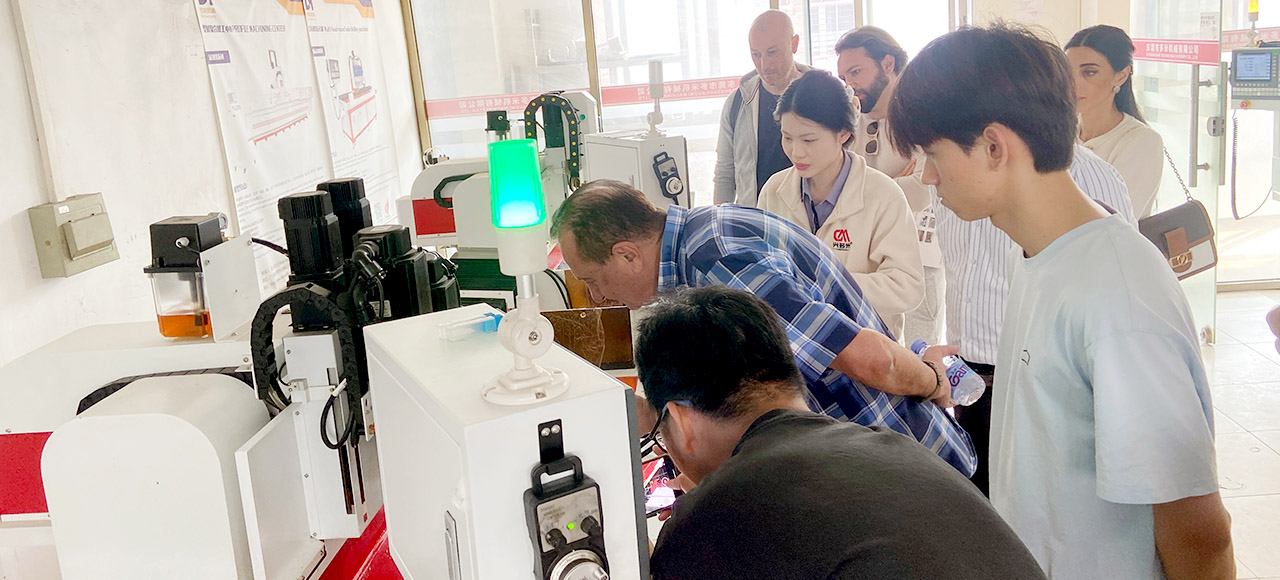

Skilled workforce shortage – Operating and maintaining these machines demands specialized training.

Material innovation – As industries adopt new alloys and composites, drilling technology must evolve.

High Speed CNC Drilling Machine DNC-3030HD

Nevertheless, continued research and development in spindle technology, cutting tools, and automation will address these challenges. The future of high-speed CNC drilling lies in greater efficiency, adaptability, and sustainability.

Conclusion

High-speed CNC drilling machines are no longer confined to niche applications; they are now at the heart of modern manufacturing across multiple industries. From automobiles and aircraft to electronics, healthcare, and renewable energy, these machines enable the production of precise, reliable, and cost-effective components. The application market for high-speed CNC drilling is poised for sustained growth, driven by technological innovation, industrial expansion, and the global push for efficiency and quality.

As manufacturing continues to evolve, high-speed CNC drilling machines will remain indispensable, ensuring companies stay competitive in a rapidly changing global economy.