Why a Thermal Friction Drilling Machine Changes the Game

If you're still relying on traditional twist drills, coolant setups, and tapping stations—it's time for a serious upgrade. Old-school drilling is messy, slow, and expensive. Tool wear, broken taps, burr cleanup—it all eats away at your profit.

That's where the thermal friction drilling machine from DUOMI CNC steps in. It's a next-gen solution built for speed, accuracy, and cost savings. No chips, no coolant, no tapping needed.

The Pain Points of Traditional Drilling (And Why You're Losing Money)

Let's talk real-world problems:

You drill a hole.

Then you switch to a tap.

It breaks halfway.

You rework the part—or worse, scrap it.

Add coolant, cleanup, and downtime to the bill.

Sound familiar?

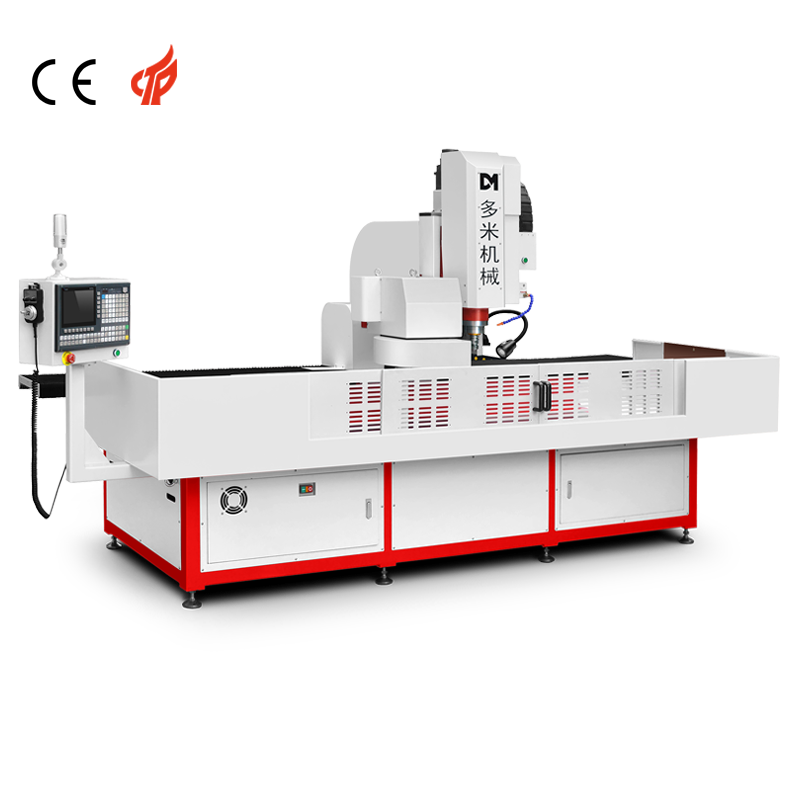

Thermal Friction Drilling Machine

This kind of cycle kills productivity and punches a hole in your margins. In high-volume production, every second and every tool counts. Traditional methods just can't keep up anymore.

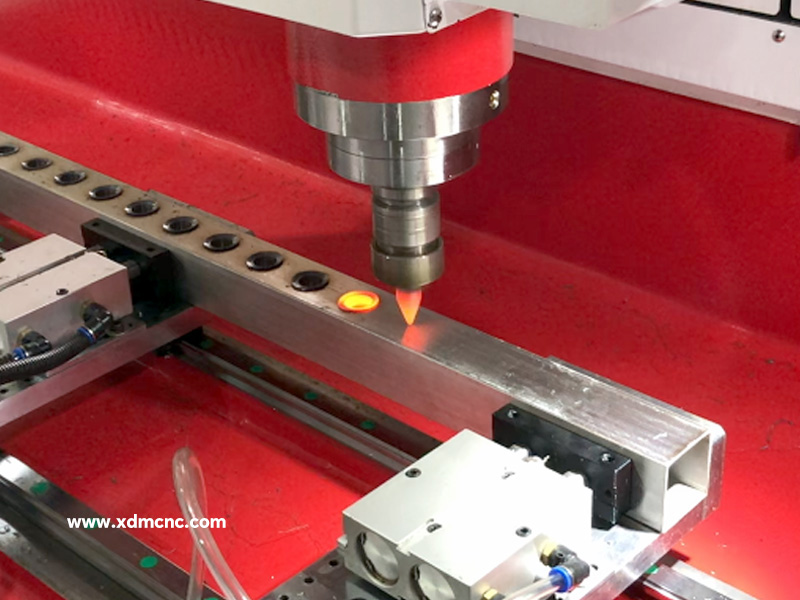

How Thermal Friction Drilling Works

The thermal friction drilling machine doesn't cut metal—it forms it. Using high-speed rotation and frictional heat, it pushes material aside to form a clean, burr-free hole with an extended bushing wall. That means:

No chips to clean up

No need for tapping

Stronger threaded holes

Longer tool life

Zero cutting fluid

And most of all—way less stress for your operators.

Automatic tool changer flow drilling and tapping machine

Thermal Friction Drilling Machine from DUOMI CNC

DUOMI CNC's friction drilling machines are designed with American manufacturers in mind. You need speed, durability, and repeatability—and we deliver.

Here's what sets us apart:

✅ High-rigidity frame and servo-controlled drive

✅ Swiss-style thermal drilling bits

✅ Compatible with steel, stainless, copper, and aluminum

✅ Fast cycle times—seconds per hole

✅ Built-in tapping via forming process

✅ Clean, eco-friendly operation (no coolant needed)

Whether you're working on square tubes, round pipes, or thin-wall profiles, our machines form strong threads without ever cutting material.

Thermal Drilling and Tapping Technology for Square Hollow Sections

Save Time, Save Tools, Save Your Sanity

Let's break it down:

Time saved — no changing tools between drill and tap.

Tools saved — friction bits last way longer than standard drills.

Clean workspace — no chips, no coolant.

Stronger parts — bushing wall adds durability to your tapped holes.

That's real money saved on every shift.

Perfect for These Industries

DUOMI CNC's thermal friction drilling machines are a favorite for:

Automotive frame manufacturers

Fitness equipment factories

Display rack and retail fixture makers

Aerospace bracket fabricators

Metal furniture and tubing production

If your shop drills and taps thousands of holes per week—you need this tech.

Thermal Drilling and Tapping for Square Tubes machine

Why Choose DUOMI CNC for Friction Drilling?

We're not just another machine supplier. At DUOMI CNC, we back our machines with real-world application support. We help you test your parts, fine-tune your process, and start producing faster.

Still not convinced? Send us your sample parts—we'll run them for free and show you the results. You’ll never go back to twist drills and broken taps again.

Your Next Best Investment Starts Now

If you want faster production, lower scrap rates, and stronger threaded connections, now's the time. The thermal friction drilling machine is the tool your shop has been missing—and DUOMI CNC is the partner to make it happen.