Why CNC Drilling and Tapping Machines Are Changing Manufacturing

If you’ve ever relied on traditional manual drilling or tapping, you already know the pain points: slow speed, inconsistent results, high labor costs, and endless downtime. For many manufacturers in aerospace, automotive, and precision engineering, these issues mean lost orders and wasted money.

That’s where a CNC Drilling and Tapping Machine from DUOMI CNC makes all the difference. Built for today’s competitive market, our machines combine fast drilling, accurate tapping, and smooth automation into one powerful solution.

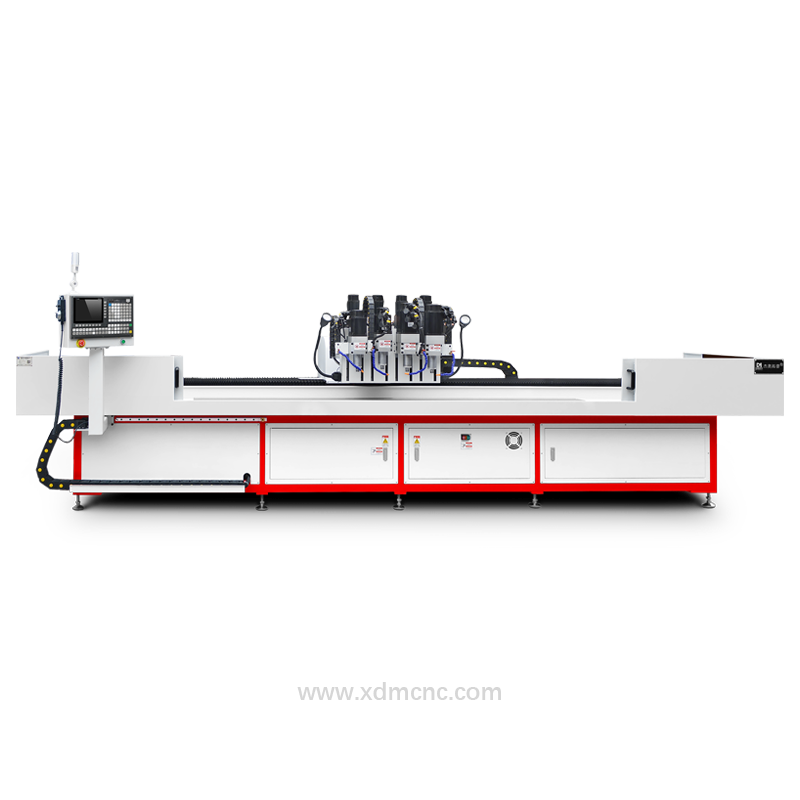

CNC Drilling and Tapping Machine with Automatic Tool Changer

CNC Drilling and Tapping Machine vs. Traditional Methods

The Problem with Old-School Drilling

Time-Consuming – Manual drilling requires constant repositioning.

Human Error – Inconsistent thread depth and misaligned holes are common.

High Labor Costs – Skilled operators are needed, driving expenses up.

Limited Scalability – Manual setups can’t keep up with large production runs.

The DUOMI CNC Advantage

With a CNC Drilling and Tapping Machine, all these pain points disappear. Precision is programmed into every movement, multiple tasks are completed in a single setup, and cycle times are cut dramatically.

Key Benefits of DUOMI CNC Drilling and Tapping Machine

1. Faster Production with Multi-Tasking

Our machines drill and tap in a single cycle. No need to switch setups or tools manually. This reduces cycle times by up to 60% compared to traditional setups.

2. Superior Accuracy

With tolerances as tight as 0.01mm, our CNC machines ensure every hole and thread is perfectly aligned. That level of precision is critical for aerospace fasteners, automotive parts, and industrial components.

3. Reduced Labor Costs

Because the CNC Drilling and Tapping Machine is fully automated, operators only need minimal training. A single worker can oversee multiple machines at once, lowering labor dependency and cutting costs.

4. Versatility Across Industries

From aluminum engine blocks to stainless steel aerospace brackets, DUOMI CNC machines handle a wide range of metals and production needs.

CNC Drilling and Tapping Machine for Aerospace & Automotive

Aerospace Applications

Aircraft components demand unmatched reliability. Our CNC Drilling and Tapping Machines deliver the accuracy and repeatability required for:

Structural airframe parts

Turbine housing drilling and threading

Lightweight metal brackets

Automotive Applications

Automotive manufacturing thrives on speed and consistency. With DUOMI CNC equipment, clients achieve:

Fast drilling of engine blocks and transmission housings

Accurate tapping of suspension and braking components

Higher throughput with minimal scrap rates

Customer Testimonials

“We switched to a DUOMI CNC Drilling and Tapping Machine for our automotive parts line, and production speed nearly doubled. What used to take hours is now done in minutes, with flawless quality.”

— Michael R., Plant Manager, Germany

“Our aerospace clients demand absolute precision. DUOMI CNC has been our trusted partner for years, delivering accuracy we can rely on.”

— David L., Aerospace Supplier, USA

Global Reach and Hassle-Free Delivery

DUOMI CNC exports worldwide, serving customers in Europe, North America, South America, and Asia. We ship directly from major Chinese ports including Shanghai, Shenzhen, Qingdao, and Guangzhou.

✅ Customers can even specify their preferred port of shipment.

✅ Fast delivery schedules to keep your production running smoothly.

✅ Comprehensive warranty and after-sales support to guarantee peace of mind.

Why DUOMI CNC?

Decades of Experience – Trusted by manufacturers worldwide.

Custom Solutions – Machines designed around your part sizes and materials.

Global Support – Technical assistance, training, and service available anytime.

Innovation-Driven – Constant upgrades to meet the latest manufacturing challenges.

Final Thoughts: Take the Lead with CNC Drilling and Tapping Machines

In today’s competitive market, sticking with outdated drilling and tapping processes isn’t an option. The DUOMI CNC Drilling and Tapping Machine delivers the speed, accuracy, and cost savings that modern manufacturing demands.

Whether you’re producing aircraft components, automotive parts, or heavy machinery, our machines give you the edge in global manufacturing.

Contact DUOMI CNC today and take your production to the next level with precision-built CNC solutions.

Email: [email protected]

WhatsApp/Phone: +852 6915 4799

Website: www.xdmcnc.com | domicncdrillingmachines.com