Why Multi-Spindle CNC Drilling & Tapping Machines Are Game-Changers

For manufacturers in aerospace, automotive, and industrial sectors, traditional drilling and tapping processes are often slow, inconsistent, and costly. Repositioning workpieces, relying on manual labor, and dealing with frequent errors can dramatically reduce productivity.

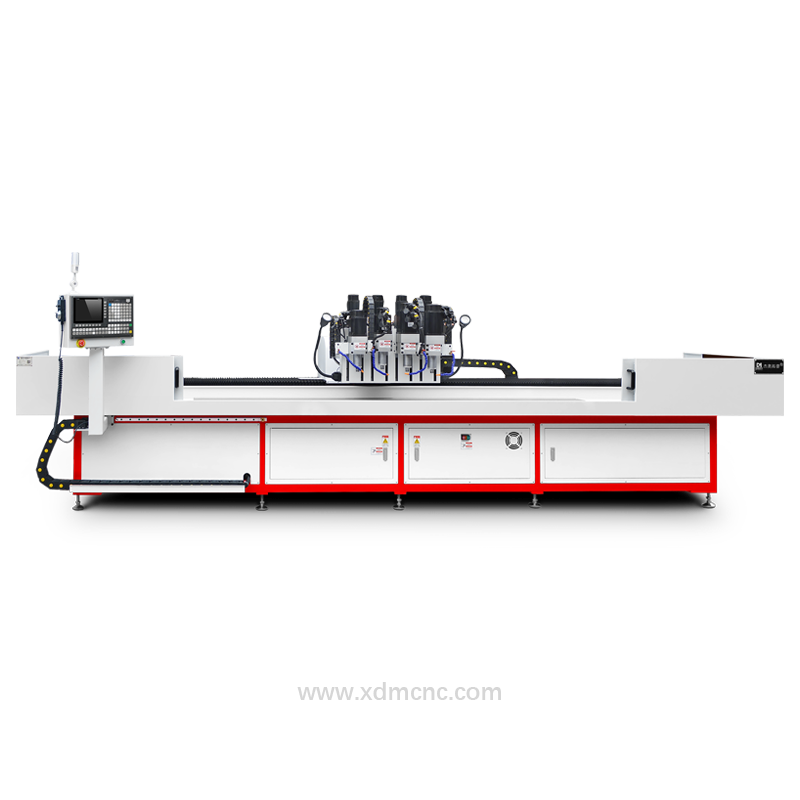

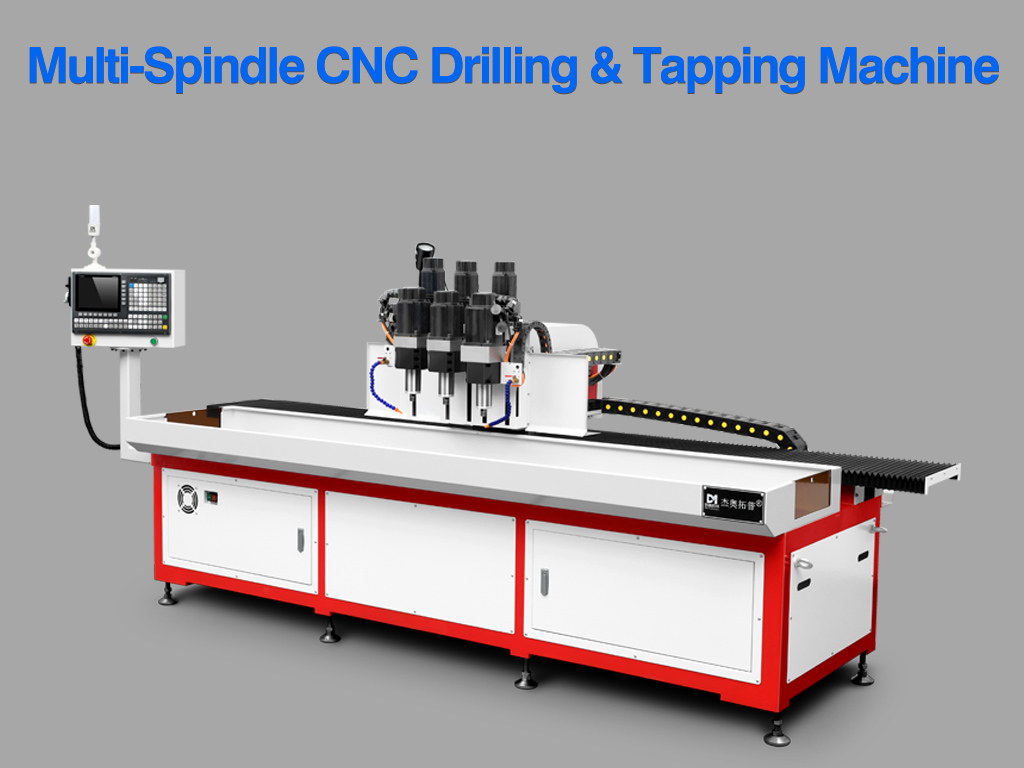

Multi-Spindle CNC Drilling & Tapping Machine

This is where the Multi-Spindle CNC Drilling & Tapping Machine from DUOMI CNC comes in. Combining multiple spindles, automated threading, and programmable precision, it solves the pain points of conventional machining while dramatically increasing throughput.

Multi-Spindle CNC Drilling & Tapping Machine vs. Traditional Methods

Traditional Challenges

Time-Consuming Operations: Manual drilling requires multiple setups.

Inconsistent Accuracy: Misaligned holes and uneven threads are common.

High Labor Costs: Skilled operators are expensive and hard to retain.

Low Scalability: Increasing production often requires adding more machines and personnel.

DUOMI CNC Advantages

Simultaneous Drilling and Tapping: Multiple spindles reduce cycle time by up to 70%.

Precision Engineering: Tolerances up to 0.01mm ensure every hole and thread meets strict requirements.

Automation: Minimal operator intervention, reducing labor costs.

Versatility: Handle aluminum, stainless steel, copper, and various alloys.

Key Features of DUOMI CNC Multi-Spindle CNC Drilling & Tapping Machines

High-Speed Multi-Spindle Productivity

With DUOMI CNC machines, multiple holes can be drilled and tapped in one setup. This reduces the need for repositioning, allowing manufacturers to achieve faster turnaround times without sacrificing quality.

Superior Accuracy

Whether producing aircraft components or automotive parts, DUOMI CNC ensures each hole and thread is precise, reducing scrap rates and eliminating costly errors common in manual machining.

Reduced Labor Requirements

A single operator can monitor multiple machines thanks to DUOMI CNC’s intuitive interface. This automation reduces reliance on skilled labor and lowers operational costs.

Multi-Spindle CNC Drilling & Tapping Machines in Aerospace and Automotive

Aerospace Applications

The aerospace industry demands flawless precision for structural components, turbine housings, and lightweight brackets. DUOMI CNC machines deliver consistent hole alignment and threading depth critical for safety and performance.

Automotive Applications

Automotive manufacturers benefit from faster drilling and tapping of engine blocks, transmission cases, and chassis components. Multi-spindle operation ensures high throughput while maintaining tight tolerances.

Global Market Reach and Reliable Shipping

DUOMI CNC machines are trusted in over 30 countries worldwide. Our Multi-Spindle CNC Drilling & Tapping Machines are shipped from major Chinese ports, including Shanghai, Shenzhen, Qingdao, and Guangzhou.

✅ Customers can specify their preferred port for delivery.

✅ Fast delivery schedules ensure production timelines are met.

✅ Comprehensive warranty and technical support provide peace of mind.

Customer Testimonials

“Switching to DUOMI CNC multi-spindle machines boosted our production line efficiency by 60%. Accuracy has never been better.”

— Michael S., Automotive Plant Manager, USA

“For aerospace parts, precision is non-negotiable. DUOMI CNC machines delivered flawless holes and threads, helping us meet strict client standards.”

— Anna L., Aerospace Supplier, Germany

Why DUOMI CNC?

Decades of Expertise: Trusted by manufacturers worldwide.

Customizable Solutions: Machines designed to meet your specific material, part size, and production requirements.

Global Support: Training, remote troubleshooting, and on-site service available.

Innovation-Driven: Continuous improvements to keep up with modern manufacturing challenges.

Take the Next Step

If you’re ready to eliminate the limitations of traditional drilling and tapping, a DUOMI CNC Multi-Spindle CNC Drilling & Tapping Machine is your solution. Boost productivity, improve accuracy, and lower costs across your aerospace, automotive, or industrial production lines.

Contact us today at [email protected] or visit www.xdmcnc.com to request a personalized quote and discuss your specific production needs.

DUOMI CNC – Precision, Speed, and Reliability in Every Multi-Spindle CNC Machine.