In the evolving world of metalworking, efficiency, precision, and automation are no longer luxuries—they're necessities. One of the most revolutionary advancements in this field is the CNC flow drilling and tapping machine, a technology that combines strength, heat, and accuracy to create holes and threads in metals like steel, stainless steel, brass, aluminum, and copper without using traditional cutting methods.

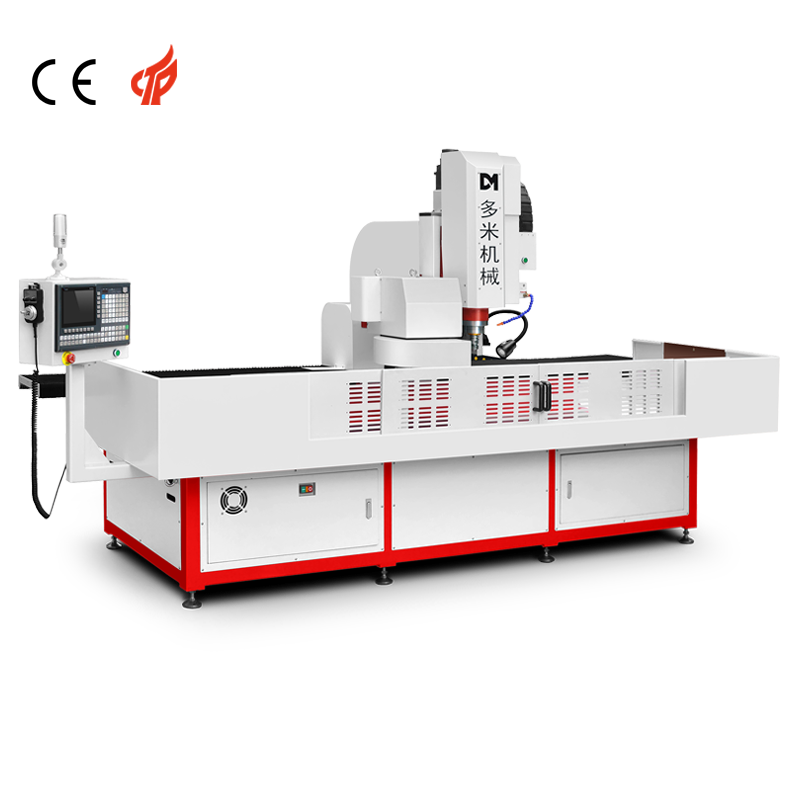

DUOMI CNC Flow Drilling and Tapping Machines

Among the top innovators in this space, DUOMI CNC has become a trusted global manufacturer of flow drilling machines and CNC flow drilling and tapping machines that are transforming how manufacturers handle metal processing tasks.

What Is Flow Drilling?

Flow drilling—sometimes called thermal drilling or friction drilling—is a process that uses frictional heat and axial force to form a hole in metal, rather than cutting or removing material.

A flow drill rotates at high speed, generating enough heat to soften the metal surface and push material aside, forming a smooth, durable bushing around the hole. This bushing becomes a reinforced area for threading, allowing stronger connections for bolts or screws.

Unlike traditional drilling, which removes material, flow drilling redistributes it—resulting in zero chip waste and a stronger joint. It's a sustainable, high-efficiency process used in industries like automotive, aerospace, HVAC, furniture manufacturing, and construction.

Why CNC Flow Drilling and Tapping Machines Are Changing the Game

The integration of CNC (Computer Numerical Control) technology into flow drilling and tapping machines has taken this method to an entirely new level.

1. Precision Meets Automation

CNC control ensures that every movement—from rotation speed to drilling depth—is precisely programmed. This automation eliminates human error, ensuring consistent hole quality across thousands of parts.

With DUOMI CNC flow drilling and tapping machines, operators can easily set parameters on the touch screen, monitor performance, and produce accurate, repeatable results without needing advanced programming experience.

2. Drilling and Tapping in One Setup

One of the biggest advantages of a CNC flow drilling and tapping machine is its ability to complete both processes—hole forming and thread tapping—in a single automated cycle.

This drastically reduces setup time and increases productivity, allowing factories to produce more parts in less time while maintaining impeccable accuracy.

3. Enhanced Structural Strength

Flow drilling creates a bushing that is three to four times the material's thickness. When threads are tapped into this bushing, the connection becomes stronger and more durable than those made using traditional drilling methods.

This makes flow drilling machines ideal for components that must withstand vibration, torque, or pressure—like automotive frames, hydraulic systems, or machinery housings.

DUOMI CNC: Innovating the Future of Flow Drilling Technology

1. Engineering Excellence

DUOMI CNC specializes in designing and manufacturing CNC flow drilling and tapping machines that offer superior speed, flexibility, and precision. Every machine is custom-built to match the client's specific material type, part size, and production volume.

With drilling stroke ranges from 400 mm up to 13 meters, DUOMI CNC machines can handle both small precision parts and large structural components with ease.

2. Smart Customization

Every DUOMI CNC flow drilling system is tailored to the customer's needs—whether they're producing aluminum housings, steel brackets, or copper fittings.

From spindle speed to tool configuration, each specification is optimized for the target material, ensuring perfect hole quality and minimal tool wear.

3. Plug-and-Play Operation

DUOMI CNC understands that not every factory has experienced programmers. That's why their machines are designed for simple, intuitive operation—operators can run full production after basic training.

The user-friendly CNC interface allows quick setup and real-time parameter adjustments, making high-precision metal drilling more accessible than ever.

Flow Drilling vs Traditional Drilling: Why It Matters

Aspect Flow Drilling Traditional Drilling

Process Heat & pressure form the hole (no material removal) Material is cut and removed

Waste Zero chips, eco-friendly Produces chips and dust

Hole Strength Reinforced bushing No reinforcement

Speed Faster for repetitive operations Slower with tool wear

Tool Life Longer Shorter due to cutting friction

Applications Ideal for thin metals and tubes Suitable for thick solids

When combined with CNC automation, the flow drilling machine becomes a powerhouse for modern manufacturing—delivering unmatched speed, precision, and efficiency.

Applications of CNC Flow Drilling and Tapping Machines

1. Automotive Industry

From chassis components to engine brackets, the flow drill and tap process ensures clean, chip-free holes that hold threads firmly. Automotive manufacturers prefer DUOMI CNC machines for their reliability and high-speed production capabilities.

2. HVAC and Plumbing

For tubes, pipes, and sheet metal components, flow drilling machines create leak-free, strong threaded connections that can withstand pressure and vibration.

3. Aerospace and Defense

In aerospace engineering, precision and durability are critical. The CNC flow drilling process ensures superior mechanical performance while reducing material waste—a key advantage for lightweight structures.

4. Furniture and Construction

Flow drilling is widely used in aluminum and steel furniture frames, as well as in building systems that require reliable fastening without welding.

Technical Highlights of DUOMI CNC Flow Drilling Machines

Drilling Diameter Range: 0.03 mm – 30 mm

Positioning Accuracy: ±0.01 mm

Compatible Materials: Stainless steel, carbon steel, aluminum, copper, brass

Automation Options: Multi-axis configurations, robotic loading/unloading, automatic tapping modules

Cooling System: Optional liquid cooling or air cooling to extend tool life

Software Interface: Intuitive CNC controller with real-time monitoring and diagnostic feedback

These machines are engineered to deliver both speed and consistency, ensuring optimal production quality for manufacturers across industries.

Advantages of Choosing DUOMI CNC

1. End-to-End Customization

Each DUOMI CNC flow drilling and tapping machine is built from the ground up based on your specific production goals—no generic models, only purpose-built systems.

2. Global Service Support

With exports to over 40 countries, DUOMI CNC provides comprehensive after-sales support, from installation to remote troubleshooting.

3. Cost Efficiency

Thanks to the integration of flow drilling and tapping in one cycle, customers report up to 40% higher productivity and 30% lower operating costs compared to conventional drilling setups.

4. Sustainable Manufacturing

Flow drilling eliminates chips and reduces energy waste, making it an environmentally friendly solution that aligns with global green manufacturing standards.

Future of Flow Drilling: Smart, Connected, and Sustainable

As the industry moves toward Industry 4.0, DUOMI CNC is integrating smart sensors, data tracking, and AI-based monitoring systems into their CNC flow drilling machines.

This next generation of flow drilling and tapping technology will allow factories to:

Predict tool wear automatically

Optimize drilling parameters in real time

Reduce maintenance downtime

Improve energy efficiency

Conclusion: Strength, Speed, and Sustainability in One Machine

The CNC flow drilling and tapping machine represents the future of precision metal processing—stronger joints, faster cycles, and smarter automation.

With DUOMI CNC's decades of expertise and global reputation for innovation, manufacturers can confidently embrace flow drilling technology to revolutionize their production lines.

Whether you're working with steel structures, aluminum components, or copper tubes, DUOMI CNC's custom-engineered flow drilling machines will help you achieve stronger threads, faster production, and long-term reliability—all in one system.

Ready to transform your metal processing?

Visit www.xdmcnc.com

or contact [email protected]

to learn how DUOMI CNC flow drilling and tapping machines can boost your productivity and precision.