Gantry CNC (Computer Numerical Control) drilling and tapping machines are essential for modern industrial manufacturing, providing high-speed, high-precision machining solutions for large-scale workpieces. As industries such as aerospace, automotive, construction, and heavy machinery continue to evolve, the demand for reliable and efficient gantry CNC drilling and tapping machines has significantly increased. This article explores the role of gantry CNC machine manufacturers, their contributions to industrial advancements, and key factors to consider when choosing a supplier.

The Importance of Gantry CNC Drilling and Tapping Machines

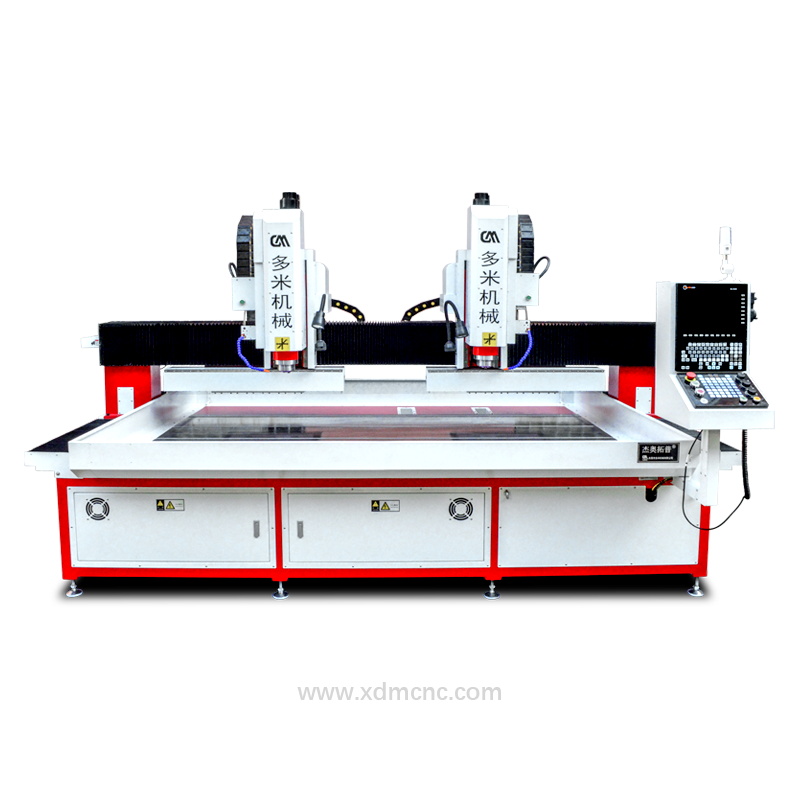

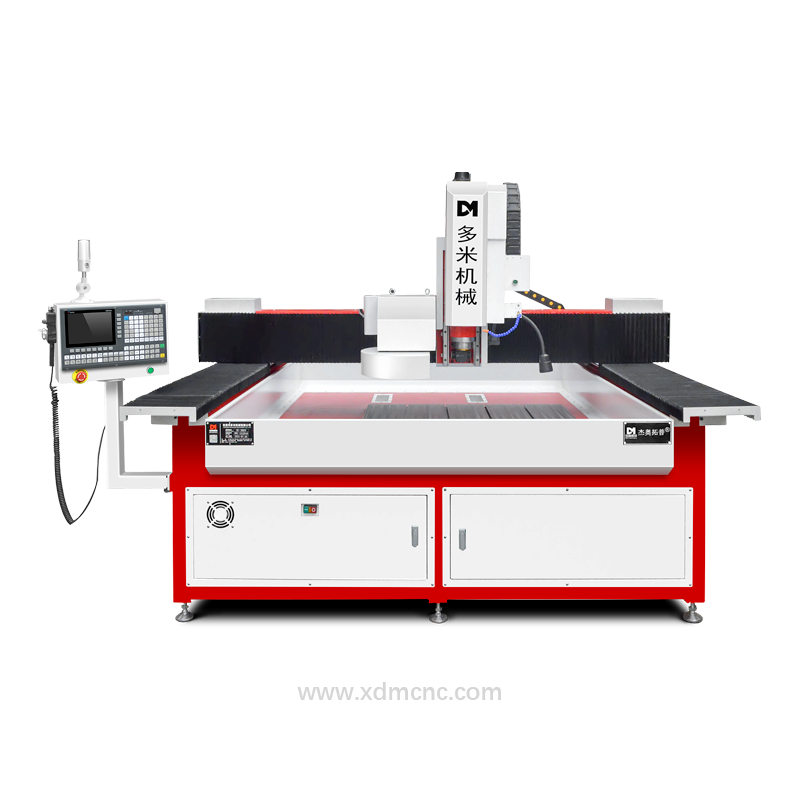

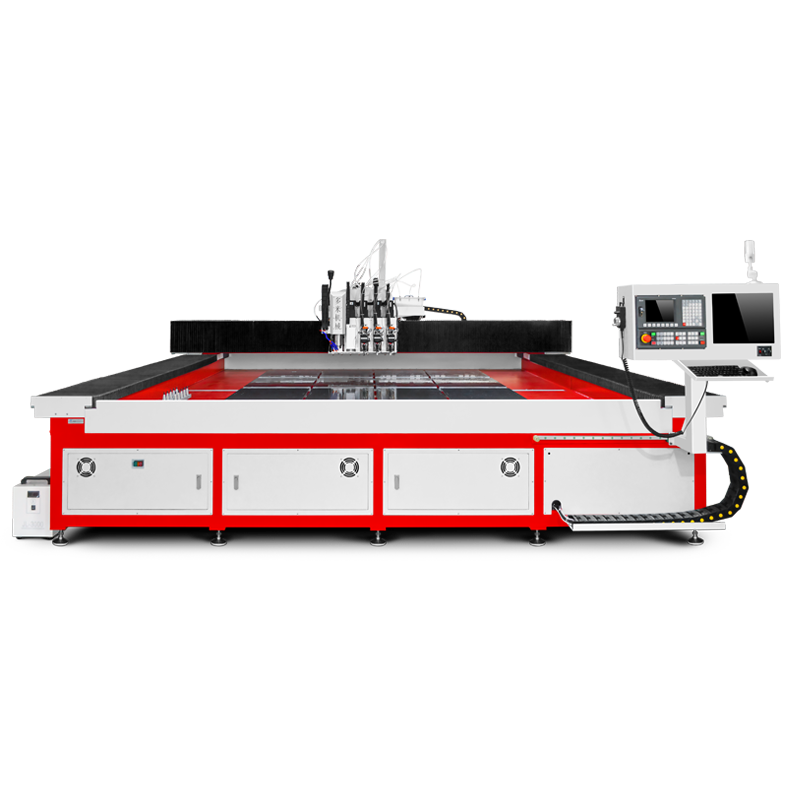

Gantry CNC drilling and tapping machines are designed for high-precision operations on large and heavy materials. Unlike conventional drilling machines, these systems utilize a gantry-style structure that allows for stable movement and enhanced accuracy across a wide work area. Manufacturers develop these machines to optimize material utilization, reduce production time, and improve overall efficiency.

Leading Applications of Gantry CNC Drilling and Tapping Machines

1. Aerospace Industry

Aircraft components require high-precision machining with tight tolerances. Gantry CNC drilling and tapping machines are used to process aluminum, titanium, and composite materials for fuselage panels, wing structures, and engine components.

2. Automotive Industry

The production of engine blocks, chassis parts, and structural components relies on high-accuracy CNC machining. Gantry CNC machines streamline mass production by delivering fast, consistent, and precise drilling and tapping operations.

3. Construction and Infrastructure

Steel beams, bridge components, and structural frames require high-quality hole drilling and threading. Gantry CNC drilling machines enable the fabrication of large-scale structural elements with superior strength and stability.

4. Shipbuilding and Heavy Machinery

The marine and heavy equipment industries use gantry CNC drilling and tapping machines for machining large metal plates, turbine housings, and industrial equipment bases. These machines ensure accuracy and durability in extreme conditions.

Key Factors When Choosing a Gantry CNC Drilling and Tapping Machine Manufacturer

Technological Innovation – Leading manufacturers invest in R&D to enhance machine performance, incorporating automation, AI-driven controls, and IoT capabilities.

Precision and Accuracy – High-quality machines feature advanced servo motors, rigid gantry designs, and precision tooling for superior hole positioning and threading.

Material Compatibility – The best manufacturers provide machines capable of handling various materials, including steel, aluminum, and composites.

Customization Options – Some industries require specialized configurations. Reliable manufacturers offer customizable solutions to meet specific production needs.

After-Sales Support and Training – Technical support, maintenance services, and operator training programs are essential for maximizing machine performance and longevity.

The Future of Gantry CNC Drilling and Tapping Machine Manufacturing

With advancements in Industry 4.0, manufacturers are integrating smart automation, real-time monitoring, and data analytics into CNC drilling systems. AI-powered machine learning algorithms optimize tool paths, reduce material waste, and enhance productivity. As industries strive for greater efficiency and precision, gantry CNC drilling and tapping machine manufacturers will continue to play a pivotal role in shaping the future of manufacturing.

Conclusion

Gantry CNC drilling and tapping machine manufacturers are at the forefront of industrial innovation, providing solutions that enhance efficiency, precision, and automation. Businesses looking to invest in these machines must consider technological advancements, accuracy, material compatibility, and after-sales support when selecting a manufacturer. As demand for high-performance machining solutions grows, manufacturers who embrace cutting-edge technologies will lead the industry, ensuring competitive advantages for their customers in global markets.