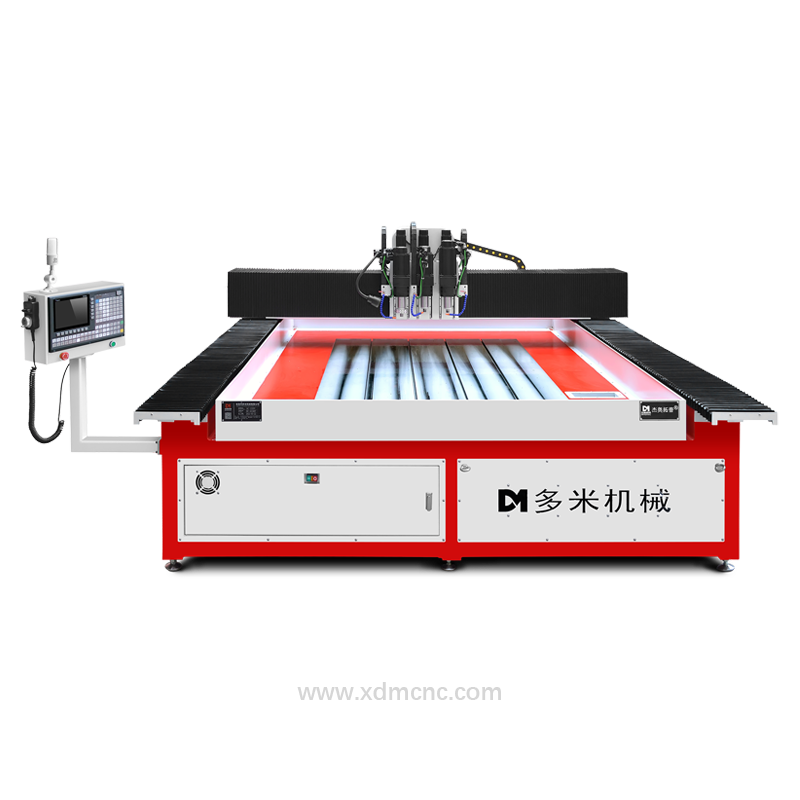

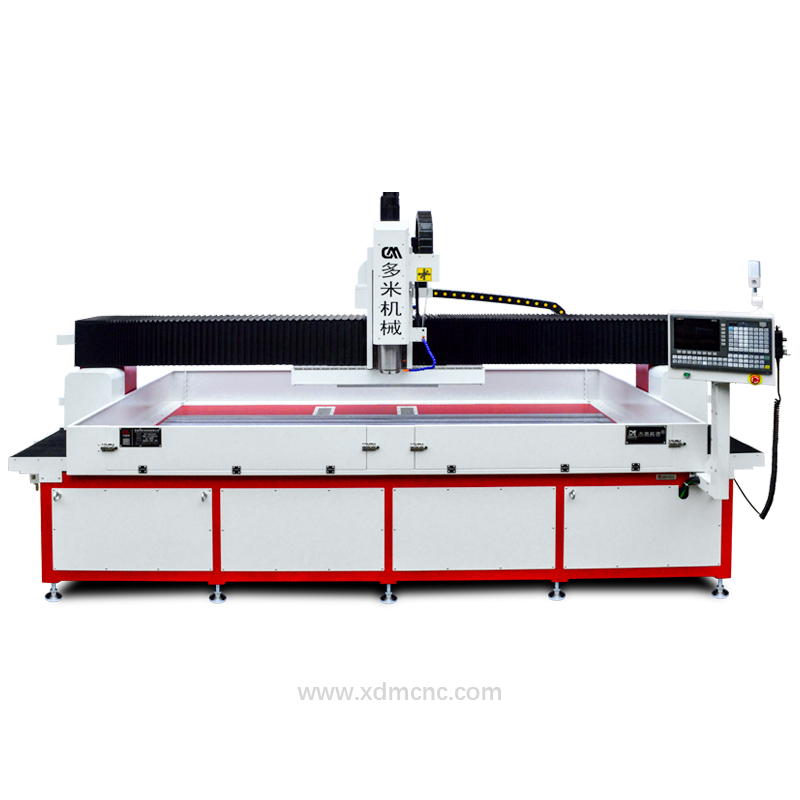

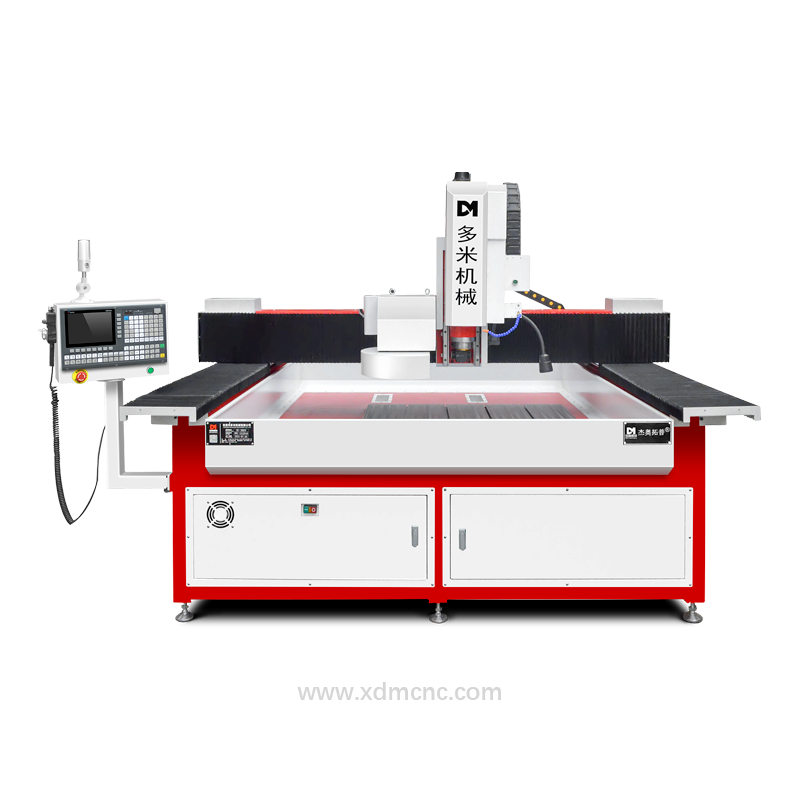

Gantry CNC Plate Drilling Machine – The Ultimate Milling Solution for Mold Sheet Metal Fabrication

Struggling with precision and efficiency when machining large mold sheet metal plates? Discover how our Gantry CNC Plate Drilling Machine can revolutionize your workflow.

Click on the image for more details

Industry Challenge

Mold manufacturers and heavy-duty fabrication shops often face multiple challenges when processing large-format sheet metal plates:

Inconsistent hole accuracy

Time-consuming manual tapping and chamfering

Separate machines needed for drilling, milling, and finishing

High labor costs and slow throughput

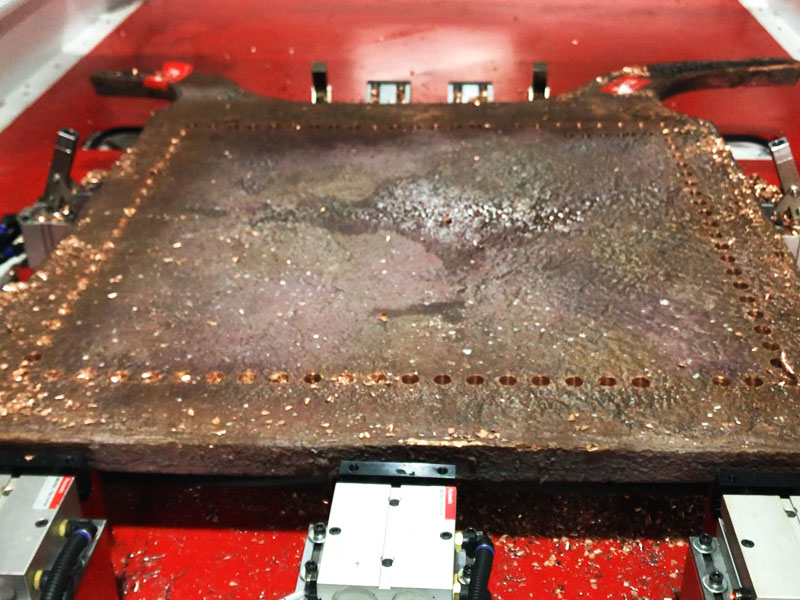

Difficulty handling large and thick plates (e.g., 5cm thick steel)

These problems result in lower productivity, quality inconsistencies, and increased operational expenses.

Our One-Stop CNC Machining Solution

The Gantry CNC Plate Drilling Machine is engineered specifically for large-format mold sheet metal milling, drilling, tapping, and chamfering—all in a single, automated platform.

Key Features:

Heavy-Duty Gantry Structure

Built for stability and precision over large surfaces, even with 5cm thick plates.

Multi-Process Integration

Perform drilling, tapping, chamfering, and milling in one setup — no need for multiple machines or repositioning.

High-Speed Spindle + Auto Tool Changer

Ensures smooth and continuous operations across variable hole sizes and machining needs.

Full CNC Control

Delivers exceptional accuracy and repeatability, even on complex molds or industrial sheet components.

Perfect for Mold Plate Fabrication

Optimized for mold steel, aluminum, and alloy plate processing in tool & die, automotive, and machinery industries.

Technical Capabilities

Plate thickness: Up to 50mm (5cm)

Material compatibility: Carbon steel, mold steel, aluminum alloys

Operation types: Drilling, tapping, chamfering, pocket milling, slot milling

Customizable working area for large sheet plates

Benefits for Your Business

✔ Save 30–50% on machining time

✔ Reduce manual labor and operator error

✔ Improve hole precision and thread strength

✔ Enhance overall production quality and speed

✔ All-in-one design lowers space and equipment investment

Trusted by Leading Mold & Sheet Metal Manufacturers

Whether you're building molds for automotive components or industrial machines, this machine helps you deliver faster, more precise results with fewer resources.

“This Gantry CNC plate machine helped us increase production by 40%, especially in thick mold plate drilling and tapping tasks. It's a real game-changer for our factory.” — Mr. Zhang, Head Engineer, Tooling Tech Co.

Get a Free Quote or Live Demo Today!

Don't let outdated machinery hold back your business.

Contact us now to learn more about our Gantry CNC Plate Drilling Machine and how it can transform your mold plate machining.

Keywords Included:

Gantry CNC plate drilling machine

Mold sheet metal milling

CNC machine for 5cm steel plates

CNC mold plate tapping and chamfering

One-stop CNC drilling solution

Large-format CNC drilling and milling machine