Boost Your Supermarket Shelf Production with Friction Drilling Technology

Say Goodbye to Weld Nuts, Improve Strength, and Cut Labor Costs

CNC Thermal Drilling and Tapping for Shelving and Display Cabinets in Cosmetics Stores, Maternity and Baby Shops, Convenience Stores, Supermarkets, Tobacco & Liquor Cabinets, Modular Stationery Racks, and Storage Shelves.

The Manufacturing Pain:

Are Rivet Nuts and Manual Tapping Slowing You Down?

Supermarket shelf and display rack manufacturers face constant challenges when joining metal square and round tubes:

Thin-walled tubing struggles to hold threads.

Manual tapping and rivet nuts reduce consistency and increase labor dependency.

Multi-step processes slow down production.

Structural weakness from traditional joining methods.

High rejection rate due to stripped threads or poor alignment.

Sound familiar? You're not alone.

These are industry-wide problems that cost time, money, and clients.

Key Advantages of Our Thermal Drilling Machine for Retail Shelving, Clothing Racks, and Display Stands

One-Step Drilling and Tapping

Our thermal drilling machine combines drilling and threading in a single cycle, dramatically improving efficiency for manufacturers of retail shelving, clothing racks, and display stands.

No Welding or Rivet Nuts Required

Eliminate the need for welding, inserts, or rivet nuts. This machine forms a solid boss in thin-walled metal tubes, providing strong, reusable threads—ideal for lightweight but sturdy retail fixtures.

Stronger Threaded Connections

The friction-generated collar around the drilled hole increases thread strength by up to 3 times, ensuring durable assembly for modular shelving and garment racks.

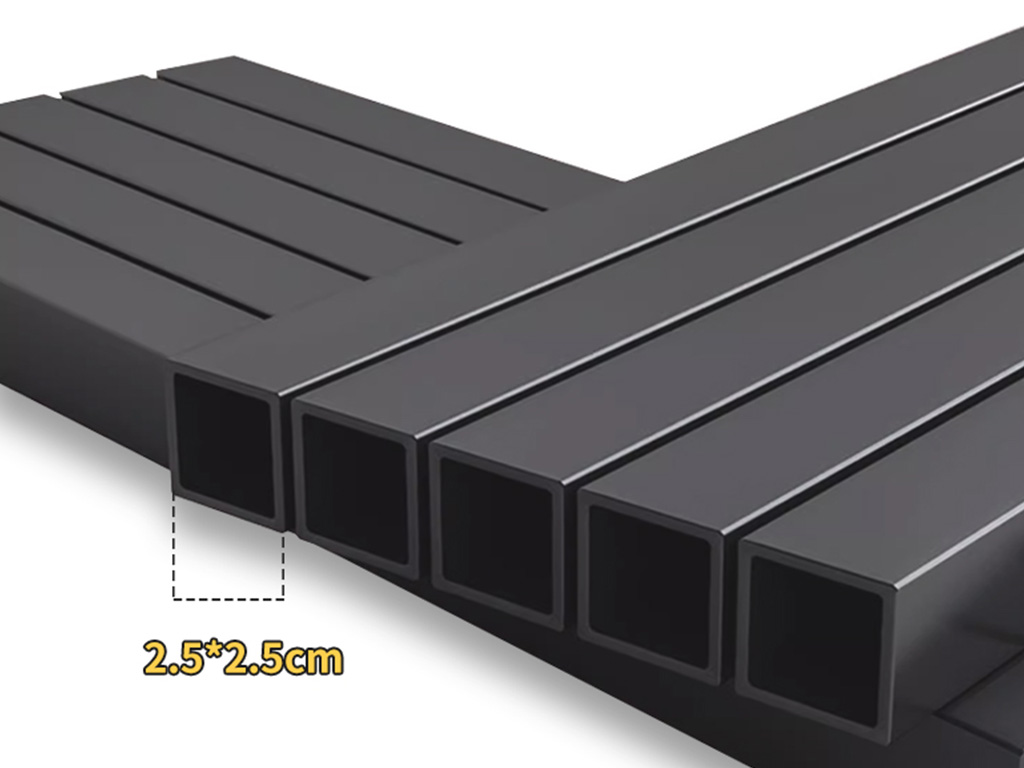

Perfect for Square and Round Tubes

Whether you're working with aluminum or steel square tubes, round pipes, or thin-wall profiles, our machine adapts to various tube sizes and materials with consistent, clean results.

Automated & CNC Controlled

Enjoy precise, repeatable results with minimal operator input. The CNC control system ensures accuracy and speed, reducing labor costs and operator error.

Ideal for High-Volume Production

Designed for mass production environments, this thermal drilling solution meets the needs of commercial fixture manufacturers by boosting output and reducing downtime.

Clean, Chip-Free Processing

Thermal drilling is an environmentally friendly process—no cutting fluids, no metal chips, and reduced maintenance. It keeps your production floor cleaner and more efficient.

Widely Used in Retail Manufacturing

Trusted by leading manufacturers of supermarket shelves, clothing racks, cosmetic display units, and fashion boutique fixtures worldwide.

thermal drilling for clothing racks

thermal drilling machine for retail shelving

CNC friction drilling display stand manufacturing

automated tapping for display furniture