Small Diameter Deep Hole Drilling – Precision Engineering for High-Performance Manufacturing

Looking to achieve perfect results in deep, narrow hole machining?

Our cutting-edge solution for small diameter deep hole drilling is designed to eliminate your production bottlenecks and deliver unmatched accuracy, consistency, and tool life.

The Problem: Precision at Depth Is Hard

In many industries — aerospace, automotive, medical, and mold-making — engineers face a common challenge:

How do you drill deep, straight, ultra-small diameter holes without tool breakage, deviation, or overheating?

Typical issues include:

Tool deflection and breakage at depths over 10× diameter.

Chips clogging the hole, leading to surface damage.

Poor lubrication, especially in micro-diameter holes.

Frequent tool changes and high operating costs.

These problems result in scrapped parts, delays, and inconsistent quality.

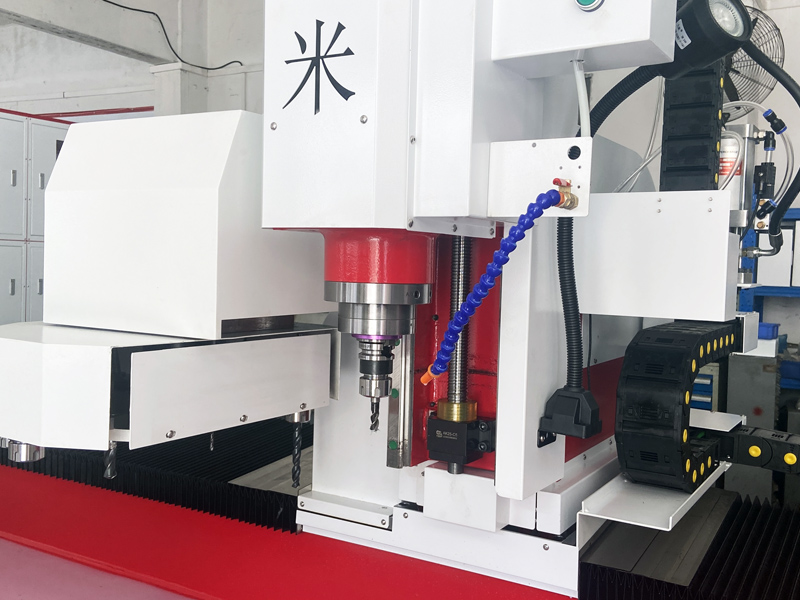

Our Solution: Engineered for Small Diameter, Built for Deep Accuracy

Our small diameter deep hole drilling systems are built with the latest technology in toolholding, coolant delivery, and CNC control. Whether you’re working with stainless steel, titanium, aluminum, or tool steels, our solution gets the job done — fast and right.

Features that Set Us Apart:

High-speed precision spindles with minimal runout for stable micro-hole drilling

High-pressure coolant systems (up to 100 bar) for effective chip evacuation and cooling

Custom micro-diameter drills optimized for strength and chip flow

Advanced CNC controls to monitor depth, torque, and tool wear in real time

Automated tool changers for uninterrupted long-batch production

Key Benefits:

✔ Accurate drilling of holes as small as 1.0 mm to depths exceeding 100 mm.

✔ Reduce tool breakage by 70%.

✔ Achieve perfectly straight holes with mirror-smooth inner surfaces.

✔ Boost productivity and reduce cycle time by 40% or more.

✔ Compatible with tight-tolerance parts and micro components.

Who Needs This?

Our solution is ideal for:

Aerospace manufacturers – fuel systems, engine components

Automotive suppliers – valve bodies, fuel rails

Medical device companies – surgical tools, orthopedic implants

Injection mold makers – internal cooling channels

Precision machine shops – small batch or large-volume production

What Our Customers Say:

“We had consistent problems with tool breakage when drilling small holes over 50mm deep. Since switching to this system, our rejection rate dropped to nearly zero. It’s a game-changer.”

— David K., Aerospace Component Manufacturer, Germany

SEO Optimization

This landing page naturally includes relevant long-tail keywords for ranking on Google:

small diameter deep hole drilling

deep micro hole machining

high precision drilling solution

deep hole drilling CNC machine

burr-free micro drilling system

micro diameter hole drilling in metal

Ready to Improve Your Drilling Precision?

Let's help you machine smarter. Our engineering team will assist you in selecting the right tools, coolant system, and machine configuration to match your exact production needs.

Contact us now for a free technical consultation

Request a demo or sample drilling report

Download our PDF guide on micro deep hole drilling best practices