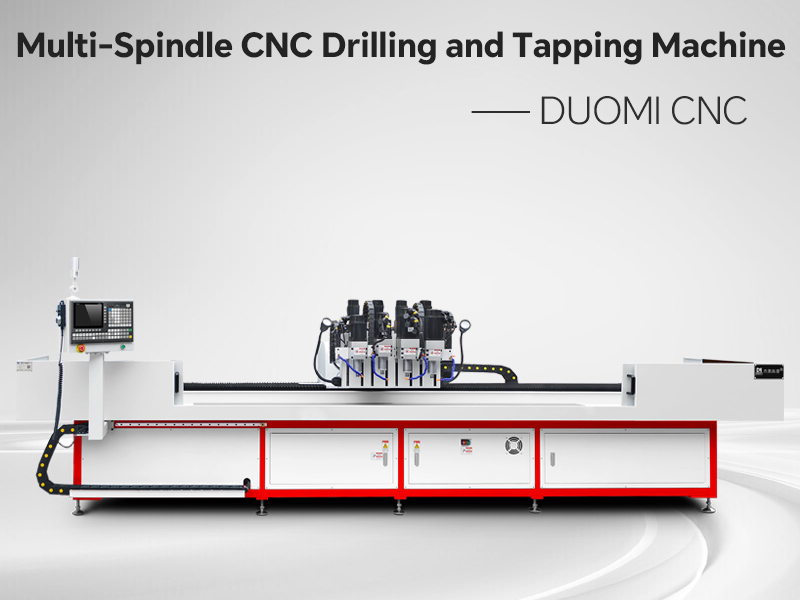

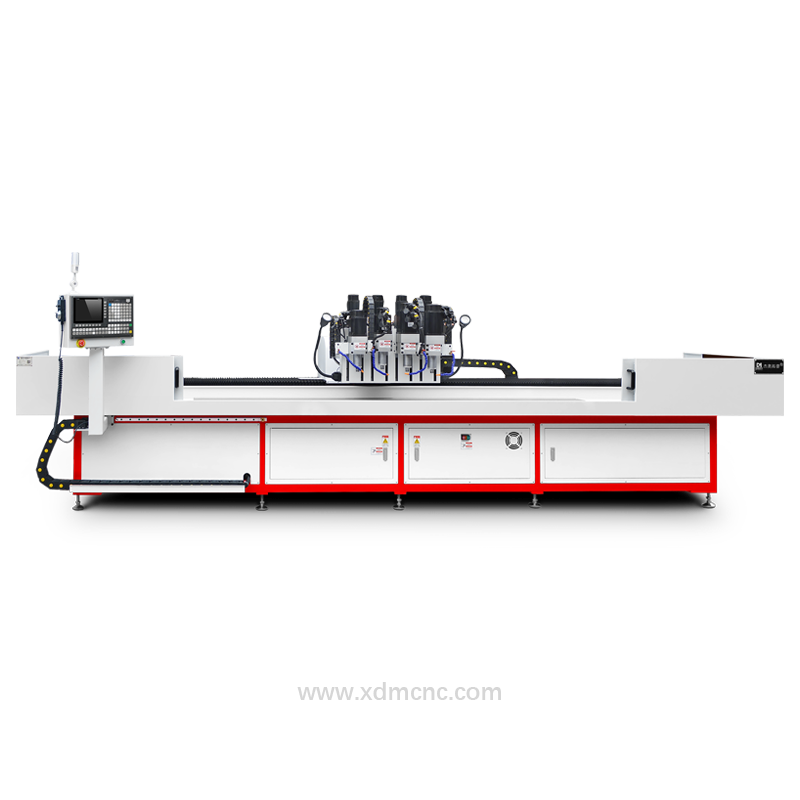

Revolutionize Production with Our Multi-Spindle CNC Machine – One-Stop Drilling, Tapping, and Milling Efficiency

In today's fast-paced manufacturing landscape, efficiency, precision, and cost-effectiveness are no longer optional — they're essential. That's where our Multi-Spindle CNC Drilling and Tapping Machine comes in, offering a revolutionary one-stop solution that seamlessly integrates drilling, tapping, and milling processes. Whether you're producing metal parts for furniture, automotive components, or fitness equipment, this advanced solution is designed to maximize productivity while maintaining unmatched accuracy.

Click on the image for more details

Why Choose a Multi-Spindle CNC Drilling and Tapping Machine?

Traditional drilling and tapping setups often require multiple machines and manual intervention, leading to longer production times, higher labor costs, and increased risk of errors. Our multi-spindle CNC solution eliminates these challenges by offering:

Simultaneous Multi-Hole Processing: With multiple spindles operating in tandem, the machine can drill and tap multiple holes at once, dramatically reducing cycle time.

Drilling, Tapping, and Milling in One Setup: Eliminate the need for transferring parts between machines. Our system supports complete processing in a single clamping.

Automated Precision: CNC control ensures micron-level accuracy and consistency, even with complex or repetitive tasks.

User-Friendly Interface: Even operators with minimal training can quickly become proficient with the intuitive touchscreen control system.

Boost Efficiency Across Industries

Our multi-spindle CNC machine is the perfect solution for a variety of sectors:

Metal Furniture Manufacturing: Ideal for processing square and round tubes, ensuring perfect hole alignment for connectors and fasteners.

Automotive Parts Production: Easily handles high-strength materials like stainless steel and aluminum, ensuring durable, high-precision parts.

Fitness Equipment Fabrication: Efficiently processes thick-walled tubes, delivering smooth, burr-free holes that meet international standards.

Retail Display Racks and Storage Systems: Achieve uniform results even in high-volume orders, enhancing visual appeal and structural stability.

Technical Advantages that Set Us Apart

When you invest in our CNC multi-spindle solution, you're gaining a production powerhouse that's engineered for performance:

High-Rigidity Structure: Built with a robust cast-iron frame to eliminate vibration during high-speed operations.

Adjustable Spindle Spacing: Flexible spindle configuration adapts to different hole patterns and part sizes.

Servo Motor Drive System: Ensures smooth, high-speed motion with precise feedback for superior control.

Thermal Drilling Compatibility: Optional support for friction drilling (thermal drilling) for thin-wall tubes and non-threaded holes.

Reduce Downtime, Increase ROI

Thanks to its automated operation, reduced manual handling, and minimal tool change requirements, this machine is a smart investment for factories aiming to:

Lower labor costs

Increase throughput

Reduce setup time

Enhance product consistency

Extend tool life

The result? A higher return on investment (ROI) and faster lead times for your clients — helping your business stay ahead in a competitive market.

Global Clients Trust Our Technology

Trusted by manufacturers across Southeast Asia, Europe, and the Americas, our multi-spindle CNC machines have been instrumental in transforming production lines. Clients consistently report:

40–60% reduction in production time

Up to 30% cost savings on labor and maintenance

Dramatic improvement in product quality and finish

We offer on-site installation, training, and 24/7 after-sales support, ensuring that your team can hit the ground running from day one.

Request a Free Consultation Today

If you're looking to optimize your manufacturing process and future-proof your factory, now is the time to invest in our Multi-Spindle CNC Drilling and Tapping Machine. Experience the power of integrated processing, precise automation, and industrial-grade performance — all in one intelligent solution.

Contact us today for a free consultation or request a quote. Let's work together to transform your production floor.

SEO Keywords Included:

Multi-Spindle CNC Machine

CNC Drilling and Tapping Machine

One-stop CNC solution

CNC machine for metal furniture

Drilling tapping and milling CNC

Thermal friction drilling

CNC production automation

Industrial CNC machine