Drilling small holes in stainless steel can be a challenging task, even for experienced machinists. Stainless steel's hardness, low thermal conductivity, and work-hardening properties make it difficult to achieve clean, precise holes — especially when the diameter is below 5 mm. However, with the right tools, techniques, and machinery, drilling small holes in stainless steel can be efficient, accurate, and highly repeatable.

In this article, we will explore the best practices, common problems, and smart solutions for successfully drilling small holes in stainless steel for industrial and commercial applications.

Why Is Stainless Steel So Difficult to Drill?

Stainless steel is prized for its corrosion resistance and strength, but those same properties also make it difficult to machine. Some of the key challenges include:

Work Hardening: Stainless steel hardens as you drill, making the process more difficult over time.

Heat Generation: Poor thermal conductivity leads to excessive heat buildup at the drill point.

Tool Wear: Standard drill bits dull quickly when used on stainless steel, especially for small diameters.

Burr Formation: Small holes often result in rough edges or burrs, which require secondary deburring processes.

Understanding these challenges is the first step to overcoming them.

Best Drilling Techniques for Small Holes

To drill small holes in stainless steel successfully, precise technique and equipment setup are essential. Here are some key recommendations:

1. Use High-Quality Drill Bits

When drilling small holes (1–5 mm) in stainless steel, cobalt high-speed steel (HSS-Co) or solid carbide drill bits are highly recommended. These materials offer superior heat resistance and maintain cutting edge sharpness longer.

2. Proper Speed and Feed Rates

Slow spindle speeds (500–1000 RPM for small holes) help reduce heat buildup.

Consistent, low feed rates help prevent drill bit breakage.

Peck drilling cycles (short, repeated drilling motions) allow chips to clear and reduce friction.

3. Coolant or Lubrication

Using cutting fluid or a mist coolant system is critical. Proper lubrication reduces friction, lowers temperature, and prolongs tool life. For CNC applications, flood coolant systems are ideal.

4. Clamping and Stability

Small-diameter drills require absolute rigidity. Secure the stainless steel workpiece firmly and ensure minimal vibration using a solid vice or fixture. Use CNC machines with low runout spindles for best precision.

CNC Machines for Drilling Small Holes in Stainless Steel

For industrial-scale production, CNC drilling machines are the most efficient and reliable option for drilling small holes in stainless steel. A CNC system provides:

Micron-level positioning accuracy

Repeatable drilling depth and diameter

Multi-axis capability for angled or complex drilling

Integrated coolant delivery systems

Support for thermal drilling for thin-walled stainless tubes

One innovative solution is the use of thermal friction drilling, where heat and pressure are used to form holes without cutting. This is especially useful for drilling small holes in thin-walled stainless steel tubing without causing deformation or requiring inserts.

Common Applications for Small Hole Drilling in Stainless Steel

Drilling small holes in stainless steel is a crucial process in various industries, including:

Automotive: Brackets, exhaust components, and sensor mounts

Aerospace: Precision fasteners and lightweight structural frames

Furniture: Stainless steel legs, tube joints, and mounting holes

Medical Equipment: Instruments and surgical tool components

Food Processing Machinery: Corrosion-resistant enclosures and piping

Whether for functionality, ventilation, or fastening, small hole drilling must meet strict quality and tolerance standards in these industries.

Tips to Improve Drilling Results

To achieve optimal results when drilling small holes in stainless steel, keep these additional tips in mind:

Always spot drill first to prevent the drill bit from walking off-center.

Use center drills or pilot holes for greater accuracy.

Avoid excessive pressure—let the drill do the work to prevent premature breakage.

Inspect tools regularly and replace dull bits to maintain hole quality.

Choose the Right Partner for Your Stainless Steel Drilling Needs

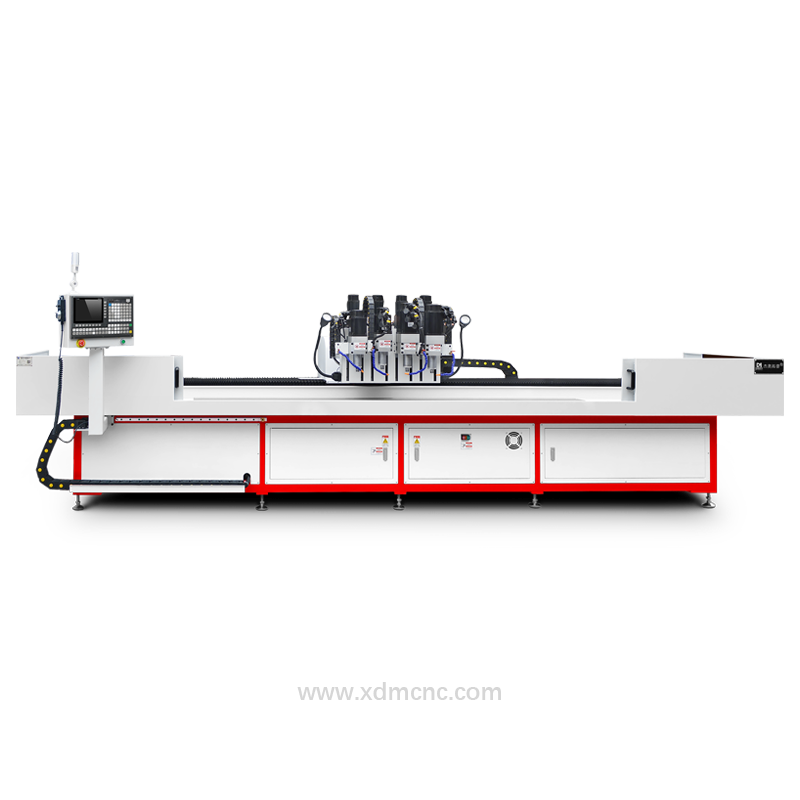

If your business relies on high-precision drilling in stainless steel components, investing in the right equipment is critical. Our company offers advanced CNC drilling machines tailored for small hole applications, with features such as:

Multi-spindle configurations

Servo-controlled feed systems

Thermal friction drilling options

High-speed precision spindles

Custom fixture design and integration

Whether you're manufacturing stainless steel furniture, automotive components, or industrial hardware, we help streamline your operations with reliable, high-performance machinery.

Final Thoughts

Drilling small holes in stainless steel is a demanding process that requires proper planning, tools, and machine control. By understanding the material, using suitable drill bits, maintaining correct speed and feed, and leveraging CNC technology, manufacturers can achieve flawless results — even with the smallest diameters.

Looking to improve your stainless steel drilling performance? Contact us today for a custom consultation on the best CNC solutions for your production line. Precision starts here.

SEO Keywords Covered:

drilling small holes in stainless steel

how to drill stainless steel

CNC drilling stainless steel

best drill bits for stainless steel

stainless steel small hole drilling machine

thermal friction drilling

CNC drilling solutions for metal

stainless steel tube drilling