Precision at Its Finest: How to Drill Small Holes in Metal with Accuracy and Efficiency

Drilling small holes in metal may sound like a simple task—but anyone in metalworking, fabrication, or industrial manufacturing knows that precision makes all the difference. Whether you're working on fine jewelry, custom automotive parts, electronics, or high-end machinery, the ability to drill small holes cleanly and accurately in various metal types is a critical skill that directly affects product quality and production efficiency.

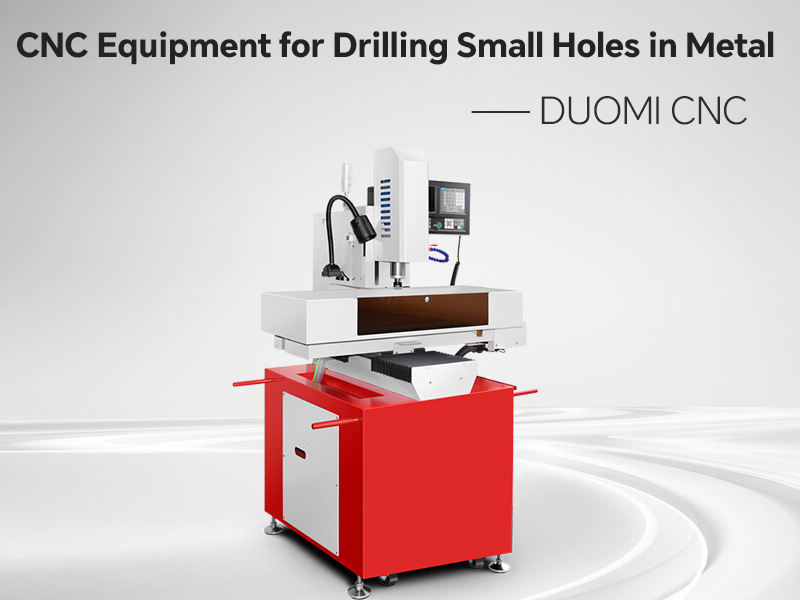

Click on the image for more details

In this guide, we explore the key challenges, tools, and solutions related to drilling small holes in metal, and introduce a professional-grade solution that simplifies the process.

Why Drilling Small Holes in Metal Is Challenging

Metals such as stainless steel, aluminum, titanium, and copper alloys present specific drilling challenges, especially when it comes to micro or small-diameter holes (typically under 5mm). Common issues include:

Tool Breakage: Small drill bits are fragile and prone to snapping under excessive pressure or incorrect speed.

Heat Buildup: Drilling generates significant heat, which can deform both the bit and the workpiece if not managed properly.

Burr Formation: Unclean exits and burrs affect downstream processing and aesthetics.

Poor Hole Accuracy: Manual operations often result in off-center or inconsistent holes, especially in high-volume production.

These challenges make it essential to use the right tools and techniques tailored to small-hole drilling in metal.

Key Considerations When Drilling Small Holes in Metal

Before you begin any metal drilling operation, keep the following best practices in mind:

1. Choose the Right Drill Bit

For small holes, cobalt or carbide-tipped drill bits are highly recommended due to their hardness and heat resistance. Consider split-point bits for improved centering.

2. Use Proper Drilling Speed and Feed Rate

Metals require slower spindle speeds and steady feed pressure. CNC machines with programmable settings offer superior control over these parameters.

3. Apply Cutting Fluid

Lubrication reduces heat and friction, extending tool life and ensuring cleaner holes.

4. Secure the Workpiece Firmly

Even the slightest movement can cause misalignment or broken bits. Use vises or clamps to stabilize the workpiece.

5. Use Pilot Holes When Necessary

For ultra-small diameters, pre-drilling with a slightly larger bit can help guide the smaller one and improve accuracy.

Introducing the Ideal Solution: CNC Drilling Machines for Micro Hole Precision

For businesses and workshops seeking consistent, high-quality results, manual drilling just isn't enough. That’s why more manufacturers are investing in CNC drilling machines that specialize in drilling small holes in metal.

These machines offer:

Micron-Level Accuracy: With advanced control systems, CNC machines can maintain exact hole diameters and depths across large production runs.

Multi-Spindle Support: Drill multiple holes simultaneously, increasing efficiency.

Automatic Tool Change: Adapt quickly to various hole sizes without manual intervention.

Touchscreen Interface & CAD Compatibility: Easily import designs and optimize tool paths.

At Duomi CNC, we've engineered a line of CNC drilling machines tailored for precision drilling in materials like stainless steel tubes, aluminum sheets, and structural metal components. Our equipment is trusted across industries includin

Real-World Applications of Small Hole Drilling in Metal

Electronics Enclosures: Small holes for buttons, LED lights, or connectors.

Metal Furniture Frames: Hidden screws and fixtures require precise boreholes.

Automotive Components: Engine brackets and custom parts demand micro-perforations for weight reduction or functionality.

Heat Exchangers: Thousands of small holes in copper or aluminum for fluid flow and heat transfer.

Regardless of the application, precision hole drilling ensures reliability, safety, and product aesthetics.

Why Choose Duomi CNC Drilling Solutions?

✅ Precision Control – Servo-driven systems for ultra-fine adjustments

✅ High-Speed Spindles – Optimized for small-diameter bits

✅ Durability – Designed for long-term industrial use

✅ Customization Available – Tailored to your part sizes and production goals

✅ After-Sales Support – Global support, training, and maintenance

Take the Next Step: Enhance Your Production Line

If you've been struggling with how to drill small holes in metal—whether manually or using outdated equipment—it’s time to upgrade to a smarter, faster, and more accurate solution. Contact Duomi CNC today to request a free demo or technical consultation. Let us help you reduce scrap, improve quality, and scale your operations.

Keywords:

drill small hole in metal, how to drill small holes in stainless steel, CNC drilling machine, precision metal drilling, micro hole drilling solutions, best way to drill small holes in aluminum, custom CNC drilling services