Revolutionizing Precision: The Power of a Micro Hole Drilling Machine in Modern Manufacturing

In today's era of miniaturization and precision, the demand for high-accuracy micro holes has skyrocketed across industries such as aerospace, medical devices, electronics, and automotive components. At the heart of this transformation is the micro hole drilling machine — a compact yet powerful CNC solution designed for ultra-fine hole processing.

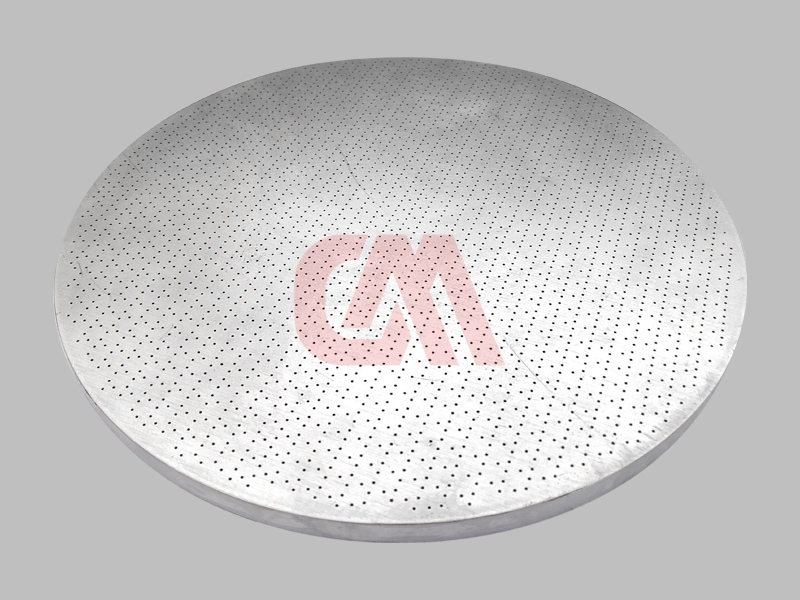

Click on the image for more details

What Is a Micro Hole Drilling Machine?

A micro hole drilling machine is a specialized CNC drilling system engineered to create ultra-small holes typically under 1mm in diameter, often as small as 0.05mm. These machines operate at ultra-high spindle speeds and are equipped with precision control systems to ensure consistent, burr-free hole quality.

Whether you're working with materials like stainless steel, titanium, aluminum, or engineering plastics, a reliable high-precision drilling system is essential to meet the strict tolerances required in today's advanced manufacturing.

Key Features and Benefits

✅ Hole Diameters as Small as 0.03mm

✅ Spindle Speeds Up to 60,000 RPM

✅ Multi-axis CNC Motion Control for Complex Patterns

✅ Advanced Cooling and Chip Removal Systems

✅ Compatible with a Variety of Metals and Alloys

If your production line involves aluminum micro hole drilling or stainless steel tube processing, these machines ensure maximum efficiency and zero compromise on accuracy.

Industries That Benefit from Micro Drilling Machines

1. Medical Devices

Micro holes are essential for devices such as surgical instruments, catheters, and implants.

2. Aerospace & Defense

Fuel nozzles, turbine blades, and other mission-critical components require micron-level accuracy.

3. Electronics

Used for PCB via-holes, sensor casings, and mini connectors where space is limited.

4. Automotive & EVs

Ideal for precision parts like fuel injector tips, filter screens, and battery connectors.

Explore our industry-specific drilling applications to see how our machines power innovation around the world.

Case Study: 0.3mm Hole Drilling in Aluminum

One of our clients in the electronics industry recently used our micro hole drilling machine to process 0.3mm holes in aluminum heat sinks. The result? A 40% reduction in defect rate and a 25% increase in production speed.

Why Choose Us as Your Micro Drilling Partner?

We offer not just machines, but tailored solutions:

Customizable Machine Configurations

Global Support & Training

OEM/ODM Services Available

Request a Quote Now

Our expertise in micro drilling technology helps manufacturers worldwide push the limits of what's possible.

Conclusion

Precision starts with the right equipment. If you're looking to improve productivity and achieve ultra-fine drilling accuracy, investing in a reliable micro hole drilling machine is the smartest move you can make.

Visit our Micro Hole Drilling Machine Solutions Page to learn more or schedule a free demo with our experts.