Revolutionizing Metalworking with the Multi-Spindle CNC Drilling & Tapping Machine

If you’re tired of the inefficiency and inconsistency of traditional drilling and tapping processes, it’s time to upgrade to something smarter — the Multi-Spindle CNC Drilling & Tapping Machine from DUOMI CNC. Designed for precision, productivity, and long-term durability, this advanced machine is redefining how manufacturers handle high-volume metal processing.

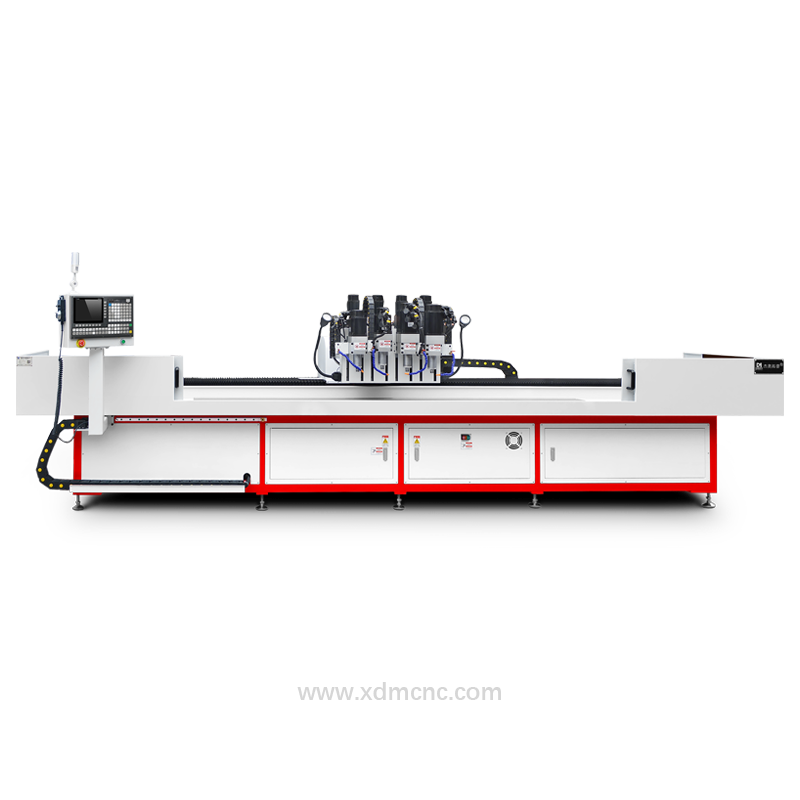

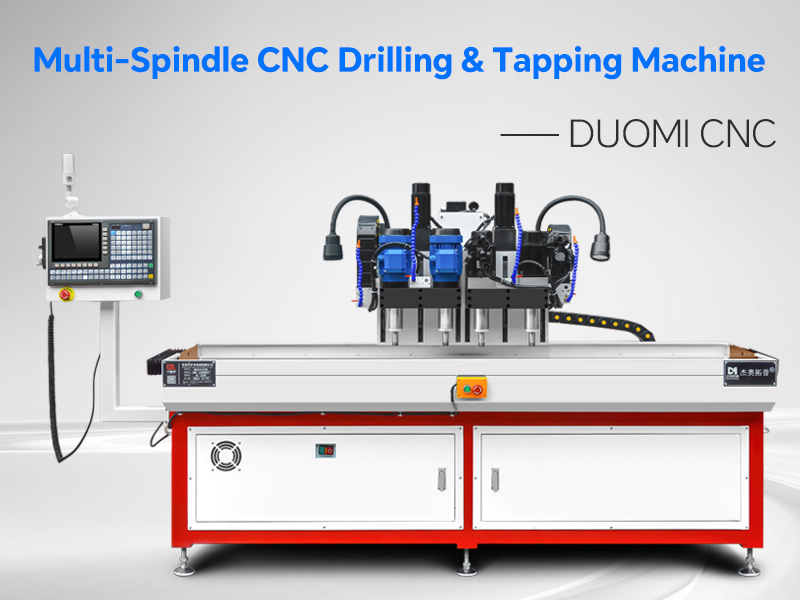

Multi-Spindle CNC Drilling & Tapping Machine

Whether you’re working with steel, aluminum, stainless steel, or brass, DUOMI CNC’s multi-spindle system ensures simultaneous, accurate drilling and tapping, saving valuable production hours while maintaining tight tolerances.

Let’s explore why thousands of metalworking professionals around the world are shifting from manual or semi-automatic drilling setups to fully automated CNC multi-spindle technology.

Why Traditional Drilling & Tapping Is Holding You Back

Before automation took over, many workshops relied on manual or single-spindle drilling machines. While these machines got the job done, they came with a set of challenges that limited growth and precision.

Low Efficiency: One hole at a time simply can’t meet the demands of modern manufacturing.

Human Error: Manual setups lead to uneven hole depth, misaligned threads, and inconsistent quality.

High Labor Costs: Skilled operators are expensive, and repetitive work often leads to fatigue and lower accuracy.

Time-Consuming Changeovers: Adjusting tools for different hole sizes or materials wastes hours each day.

These pain points cost manufacturers thousands of dollars annually. That’s where the DUOMI CNC Multi-Spindle Drilling & Tapping Machine steps in — transforming traditional production lines into fully automated, precision-driven systems.

Multi-Spindle CNC Drilling & Tapping Machine — A Productivity Powerhouse

The multi-spindle design is the core of this machine’s efficiency. Instead of drilling one hole at a time, multiple spindles work simultaneously, allowing you to complete dozens of holes in one operation.

Here’s how DUOMI CNC turns this concept into real-world results:

Unmatched Speed and Accuracy

Each spindle is powered by a servo-controlled motor, ensuring synchronized movement and stable feed rates. With precision positioning down to microns, you get flawless hole alignment and consistent thread quality — even across long production runs.

Flexible Multi-Axis Capabilities

DUOMI CNC’s system can be configured with 3-axis, 4-axis, or 5-axis setups, enabling drilling and tapping on different planes and complex geometries. Whether it’s rectangular tubes, round pipes, or aluminum profiles, the machine adapts effortlessly to your production requirements.

Multi-Spindle CNC Drilling & Tapping Machine

Heavy-Duty Build for Continuous Operation

The robust cast-iron structure ensures vibration-free performance, while the high-rigidity guideways and spindle bearings guarantee durability under heavy loads. Even in demanding conditions, this machine maintains accuracy and reliability for years.

Smart Features That Simplify Complex Production

Modern manufacturers need more than just speed — they need intelligence and automation. The DUOMI CNC multi-spindle system comes with advanced features that make high-precision production simpler than ever.

Intelligent Control System

The machine is powered by a user-friendly CNC controller, offering full digital control of spindle speeds, drilling depths, and feed rates. Operators can easily save and recall machining programs, reducing setup time and ensuring consistent performance.

Automatic Tool Change (ATC)

For workshops that handle multiple operations, the ATC system allows seamless switching between drill bits and taps without manual intervention. This dramatically boosts efficiency and reduces downtime.

Real-Time Monitoring

The built-in diagnostic system tracks spindle performance, tool wear, and cycle times in real time — helping you predict maintenance needs and avoid unexpected downtime.

Multi-Spindle CNC Drilling & Tapping Machine for Various Industries

DUOMI CNC’s multi-spindle CNC drilling and tapping machine is widely used in industries that require high-precision and high-speed drilling across multiple materials and shapes:

Furniture and Display Racks: Drilling and tapping metal tubes and joints with consistent accuracy.

Automotive and Motorcycle Components: Producing high-strength threaded holes in chassis and engine parts.

Fitness Equipment Manufacturing: Processing steel tubes and brackets for durable, aesthetic structures.

Electrical Enclosures and Metal Frames: Achieving perfect hole alignment for mounting and assembly.

DUOMI CNC — Quality Manufacturing Backed by Global Shipping and Support

When you invest in a DUOMI CNC machine, you’re not just buying a piece of equipment — you’re choosing a partner dedicated to your success.

Fast Worldwide Delivery

All DUOMI CNC machines are shipped directly from major Chinese ports including Shanghai, Shenzhen, Qingdao, and Guangzhou. We also support custom port selection based on client preference. With our optimized logistics network, you can expect quick lead times and hassle-free export handling.

Reliable After-Sales Support

Every machine is backed by a comprehensive warranty policy and lifetime technical assistance. Our service team provides remote troubleshooting, video guidance, and spare parts supply, ensuring your operation never stops.

Tailored Solutions

From machine configuration to spindle layout, DUOMI CNC offers customized design options to fit your specific production requirements. Whether you need high-speed drilling, deep-hole tapping, or multi-surface processing, we’ll build a solution that works for you.

Why Choose DUOMI CNC Multi-Spindle Drilling & Tapping Machines

Proven Efficiency: Up to 3–5 times faster production rates compared to single-spindle setups.

Superior Precision: High spindle synchronization ensures thread and hole consistency.

User-Friendly Interface: Intuitive control system reduces operator learning time.

Versatile Applications: Suitable for round tubes, square pipes, plates, and custom metal profiles.

Global Shipping & Service: Quick dispatch from China’s major ports and professional after-sales support.

Final Thoughts: Transform Your Workshop into a Productivity Engine

If your production line still relies on single-spindle drilling or manual tapping, you’re missing out on massive time and cost savings. The DUOMI CNC Multi-Spindle CNC Drilling & Tapping Machine offers a complete solution — precision, automation, and efficiency in one robust package.

From Shanghai to Los Angeles, from Shenzhen to Dubai, DUOMI CNC is helping global manufacturers streamline their production, cut labor costs, and achieve world-class machining quality.

Upgrade your workshop today with DUOMI CNC — where speed meets precision, and every spindle drives your success forward.

Keywords naturally embedded:

multi spindle CNC drilling machine, multi spindle CNC tapping machine, DUOMI CNC, CNC drilling and tapping machine, multi spindle drilling system, CNC drilling machine for metal, CNC tapping solutions, high-speed CNC drilling, precision CNC machining