The Smarter Way to Upgrade Your Workshop — Direct from the Source

If you're running a metalworking or fabrication business, you already know how much time and money gets wasted on slow, outdated drilling and tapping methods. You've probably also noticed that buying machines through middlemen adds unnecessary cost, communication gaps, and delays.

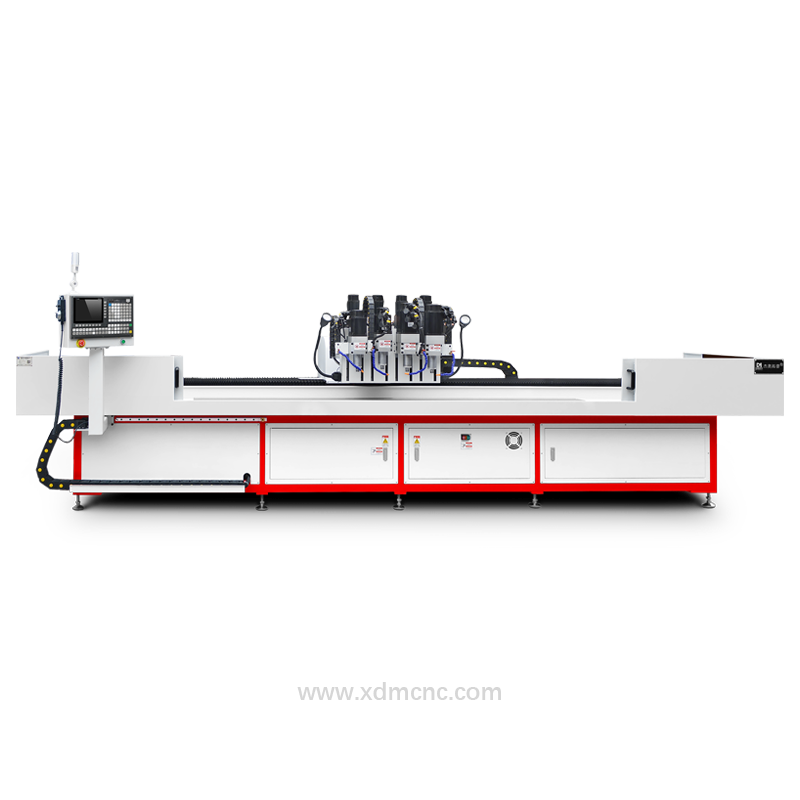

CNC drilling and tapping machine manufacturer — DUOMI CNC

That's why DUOMI CNC is changing the game with direct sales from our CNC drilling and tapping machine manufacturing facility in China — giving you factory pricing, faster delivery, and 100% quality assurance.

When you buy straight from the manufacturer, you're cutting out the middle layer — and gaining direct access to advanced, high-precision CNC drilling and tapping solutions that boost productivity and profits.

CNC Drilling and Tapping Machine Manufacturer Direct Sales — Why It Matters

Many buyers think they're saving money by purchasing from distributors or resellers. But in reality, every extra layer between you and the factory adds cost and reduces flexibility.

Here's why going direct-to-manufacturer with DUOMI CNC makes perfect business sense:

Lower Costs, Higher Value

Distributors often mark up prices by 15–30%. DUOMI CNC's factory-direct pricing means you get advanced CNC technology without the inflated costs. You pay for engineering and performance, not for middleman commissions.

Customized Solutions

Unlike dealers, manufacturers can tailor machines to your production requirements — whether it's drilling aluminum profiles, tapping thick-walled steel pipes, or creating threaded holes in stainless structures.

At DUOMI CNC, we design and build each CNC drilling and tapping machine to fit your exact production scenario, helping you save setup time, reduce waste, and maintain consistent precision.

Transparent Communication

Working directly with the factory means clear communication, faster responses, and a deeper technical understanding of your project. Our engineering team speaks your language — production speed, tolerance, tool life, and ROI.

The Problem with Traditional Drilling and Manual Tapping

Let's face it — traditional drilling and tapping setups simply can't keep up with modern production demands.

Here are the common pain points we hear from manufacturers worldwide:

Low throughput: Single-spindle or manual drilling means one hole at a time — too slow for today's batch production.

Inconsistent results: Hand tapping and manual feed rates cause uneven hole depths and broken threads.

High labor costs: Skilled operators are expensive, and fatigue leads to errors.

Frequent tool changes: Manual retooling eats up valuable hours.

If these sound familiar, then it's time to move to a CNC drilling and tapping system that automates the process, increases output, and keeps quality consistent 24/7.

DUOMI CNC Drilling and Tapping Machines — Precision, Speed, and Durability

As one of China's leading CNC drilling and tapping machine manufacturers, DUOMI CNC focuses on combining speed, strength, and precision in every model we produce.

Multi-Axis Flexibility

Our machines come with 3-axis, 4-axis, and even 5-axis configurations, allowing you to drill and tap on multiple surfaces without repositioning your workpiece. Perfect for rectangular tubes, round pipes, metal frames, or aluminum extrusions.

High-Speed and Synchronized Tapping

Each spindle is servo-driven, guaranteeing synchronized motion for precise hole positioning and flawless thread cutting — no misalignment, no vibration.

Rugged Build for Long-Term Stability

DUOMI CNC machines are built with high-rigidity cast iron bases and linear guideways, ensuring long-lasting accuracy even under continuous heavy-duty operations.

Smart Automation

Equipped with a user-friendly CNC control system, operators can easily program drilling depths, tapping speeds, and hole patterns — ensuring repeatable results and reducing dependency on manual labor.

Real-World Applications Across Multiple Industries

DUOMI CNC drilling and tapping machines are trusted globally across industries where speed and accuracy define profitability:

Furniture and Display Racks: High-speed drilling of steel and aluminum tubes for connector assembly.

Automotive and Motorcycle Parts: Consistent tapping of threaded holes in brackets, frames, and engine components.

Fitness Equipment: Efficient drilling and tapping on round and square metal tubes with high torque.

Electrical Cabinets & Metal Enclosures: Perfect alignment for screw holes and panel fittings.

Every model from DUOMI CNC is designed to handle a wide range of metal materials — from light aluminum profiles to thick-walled stainless steel — ensuring you get one solution for all your drilling and tapping needs.

Global Shipping, Reliable Warranty, and Hassle-Free Service

Buying factory-direct doesn't mean you're on your own. DUOMI CNC delivers global coverage and end-to-end customer support — from order to installation.

Fast Global Delivery

We ship directly from major Chinese ports including Shanghai, Shenzhen, Qingdao, and Guangzhou, and can also accommodate your preferred port upon request. Our logistics team ensures on-time shipment and safe packaging, giving you confidence from the moment you place your order.

Comprehensive Warranty Policy

Every DUOMI CNC drilling and tapping machine comes with a worry-free warranty covering parts, labor, and technical support. You'll also receive lifetime maintenance guidance and remote troubleshooting assistance from our service engineers.

Rapid Response After-Sales

Our dedicated after-sales team is available via WhatsApp, email, or video call to assist with installation, setup optimization, or technical adjustments — ensuring your machine runs flawlessly from day one.

Why DUOMI CNC Is the Smart Choice for Manufacturers

Factory-Direct Advantage: No middleman, no hidden markups — buy directly from the manufacturer.

Proven Engineering Quality: Precision-built machines backed by decades of CNC experience.

Flexible Configuration: Available in single, dual, and multi-spindle versions.

Global Shipping: Fast dispatch from Shanghai, Shenzhen, Qingdao, and Guangzhou.

Customizable Solutions: Designed to fit your unique production demands.

Reliable Warranty & Support: 24/7 technical service, lifetime maintenance, and easy spare parts access.

Final Thoughts: Go Direct, Go Smarter — Choose DUOMI CNC

In today's competitive manufacturing world, efficiency and reliability define success. Why spend extra on middlemen when you can buy direct from the CNC drilling and tapping machine manufacturer — DUOMI CNC?

We offer high-performance, fully automated solutions designed to replace outdated manual processes and help your business stay ahead of the competition.

With direct factory pricing, global port shipping options, and worry-free after-sales support, DUOMI CNC ensures your investment delivers long-term value and productivity.

Upgrade your workshop today. Choose DUOMI CNC — where precision meets productivity, and every drill, tap, and thread is engineered for success.

Keywords naturally embedded:

CNC drilling and tapping machine manufacturer, direct sales CNC drilling machine, DUOMI CNC, CNC tapping solutions, factory direct CNC machine, multi spindle CNC drilling and tapping, CNC machine from China manufacturer, precision drilling and tapping equipment, high-speed CNC tapping machine