Unlocking the Full Potential of Aluminum Machining

Aluminum is everywhere — from automotive frames and aircraft components to furniture profiles and electrical enclosures. It’s lightweight, corrosion-resistant, and easy to form. But when it comes to drilling and tapping aluminum, precision and speed make all the difference between success and costly rework.

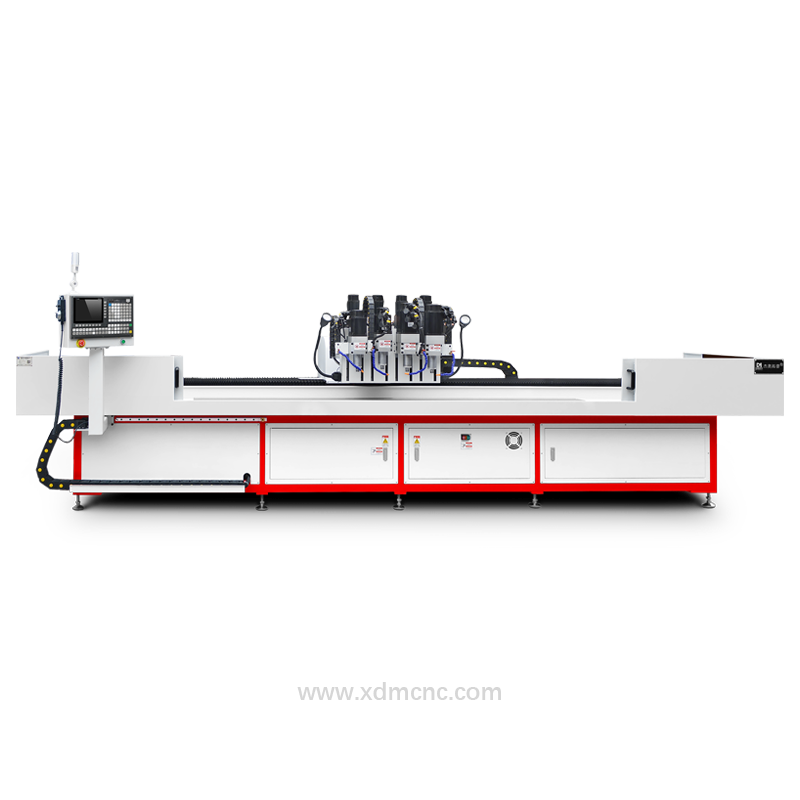

That’s where the CNC drilling and tapping machine from DUOMI CNC comes in — engineered to handle high-speed, high-accuracy operations across aluminum sheets, profiles, and tubes with remarkable consistency.

If your workshop still relies on manual or semi-automatic drilling, it’s time to see what real efficiency feels like.

The Challenge of Drilling and Tapping Aluminum

Aluminum might seem soft compared to steel, but it brings unique challenges:

Chip Control Issues: Aluminum tends to produce long, stringy chips that can clog cutting paths.

Burr Formation: Without proper speed and feed rates, holes often have rough edges that require manual deburring.

Thread Quality: Manual tapping can lead to poor thread integrity or tool breakage.

Inconsistent Hole Alignment: Traditional drilling setups struggle with maintaining consistent hole spacing across long profiles.

Aluminum pipe drilling and tapping

For manufacturers producing hundreds or thousands of aluminum parts per day, these issues quickly turn into wasted time, high scrap rates, and reduced profit margins.

How a CNC Drilling and Tapping Machine Solves These Problems

The CNC drilling and tapping machine offers a complete digital solution to the inefficiencies of manual machining. DUOMI CNC’s system integrates intelligent control, automated feeding, and multi-axis precision movement — giving manufacturers the edge they need.

Smart Automation

With a pre-programmed CNC control system, you can set exact drilling depths, spindle speeds, and thread parameters for each hole. The machine executes every operation with micron-level accuracy, ensuring consistency across every workpiece.

High-Speed Drilling

Aluminum’s soft composition allows for high RPM drilling — and DUOMI CNC machines are designed to take advantage of that. High-speed spindles and servo-driven axes enable rapid feed rates without sacrificing precision.

Perfect Threading, Every Time

Automated tapping functions ensure each thread is perfectly formed — no misalignment, no tool slippage. Combined with high-precision torque control, this machine guarantees durable, smooth, and accurate threads.

Reduced Tool Wear

Using optimized cooling and lubrication systems, DUOMI CNC machines minimize heat generation and chip adhesion — keeping tools sharper, longer, and reducing maintenance costs.

Designed for Aluminum Profiles, Tubes, and Plates

DUOMI CNC’s drilling and tapping machines are engineered for versatility, capable of handling various aluminum components across multiple industries.

Long Aluminum Profiles

Whether it’s window frames, display racks, or automotive rails, the machine ensures straight-line drilling across several meters of aluminum without deviation.

Aluminum Tubes and Extrusions

For furniture, fitness equipment, and industrial structures, the CNC drilling and tapping machine maintains consistent hole depth and spacing — even on curved or hollow surfaces.

Aluminum Sheets and Panels

Ideal for aerospace parts, electrical cabinets, or decorative panels, DUOMI CNC machines achieve clean, burr-free holes with precision-controlled feed and spindle synchronization.

The DUOMI CNC Advantage

When it comes to aluminum machining, DUOMI CNC has built its reputation on precision, innovation, and durability.

Multi-Spindle Options

Choose between single-spindle, dual-spindle, or multi-spindle configurations to match your production needs. Multiple spindles allow simultaneous drilling and tapping, drastically cutting cycle times.

Customizable Systems

From 3-axis to 5-axis configurations, DUOMI CNC designs each system based on your product dimensions and hole patterns. No matter how complex the job, there’s a tailored solution for it.

Intelligent Interface

The user-friendly CNC interface allows quick program setup, automatic cycle execution, and on-screen error detection. Operators can easily manage complex hole arrays with just a few commands.

Precision Built to Last

Every DUOMI CNC machine is built with a rigid cast-iron structure and high-rigidity guideways for stable performance and zero vibration — even during continuous high-speed drilling operations.

Real-World Applications of CNC Drilling and Tapping on Aluminum

DUOMI CNC’s machines are trusted by global manufacturers across various industries:

Furniture & Display Frames: Fast drilling and tapping of lightweight aluminum profiles for connectors.

Automotive Parts: Creating precise threaded holes in chassis, rails, and brackets.

Electrical & Lighting Fixtures: Clean holes for mounting and assembly of enclosures.

Architectural Structures: Reliable processing of long aluminum beams and panels for doors, windows, and facades.

Aerospace Components: Ultra-precise drilling of aluminum alloys for lightweight, high-strength parts.

Why Choose DUOMI CNC

Factory-Direct Manufacturing: No middleman markup — you buy directly from the source.

Professional Engineering Support: Our technicians assist with programming, setup, and optimization.

Durable Construction: Designed for continuous, heavy-duty production.

Flexible Solutions: Custom spindle layouts, automatic tool changers, and multi-axis setups available.

Comprehensive Warranty & Lifetime Service: DUOMI CNC ensures your investment remains productive for years to come.

Final Thoughts: Redefine Efficiency with CNC Precision

Aluminum machining demands speed, accuracy, and consistency — and that’s exactly what the DUOMI CNC drilling and tapping machine delivers.

From small workshops to full-scale production lines, our systems help manufacturers boost output, reduce labor dependency, and achieve repeatable results with minimal waste.

When you’re ready to replace manual setups and step into a smarter future of metalworking, DUOMI CNC is your trusted partner.

Because every hole, every thread, and every second counts.

Keywords naturally included:

CNC drilling and tapping machine, DUOMI CNC, CNC drilling machine for aluminum, CNC tapping machine for aluminum profiles, precision CNC aluminum drilling, automated tapping for aluminum tubes, CNC drilling and tapping equipment