Friction Drill Bit: High-Efficiency Hole Forming with DUOMI Thermal Drilling Technology

In the era of lightweight metal fabrication and high-precision assembly, the friction drill bit has emerged as a revolutionary tool that redefines how holes are formed in thin-walled metal tubing. Unlike conventional drilling tools that rely on cutting and material removal, a friction drill bit utilizes heat generated by friction to plastically deform the material and create a clean, high-strength hole without chips or the need for auxiliary fasteners. Among global manufacturers, DUOMI stands out as a trusted innovator in friction drilling solutions, offering durable and performance-driven thermal friction drill bits for industrial applications.

What is a Friction Drill Bit?

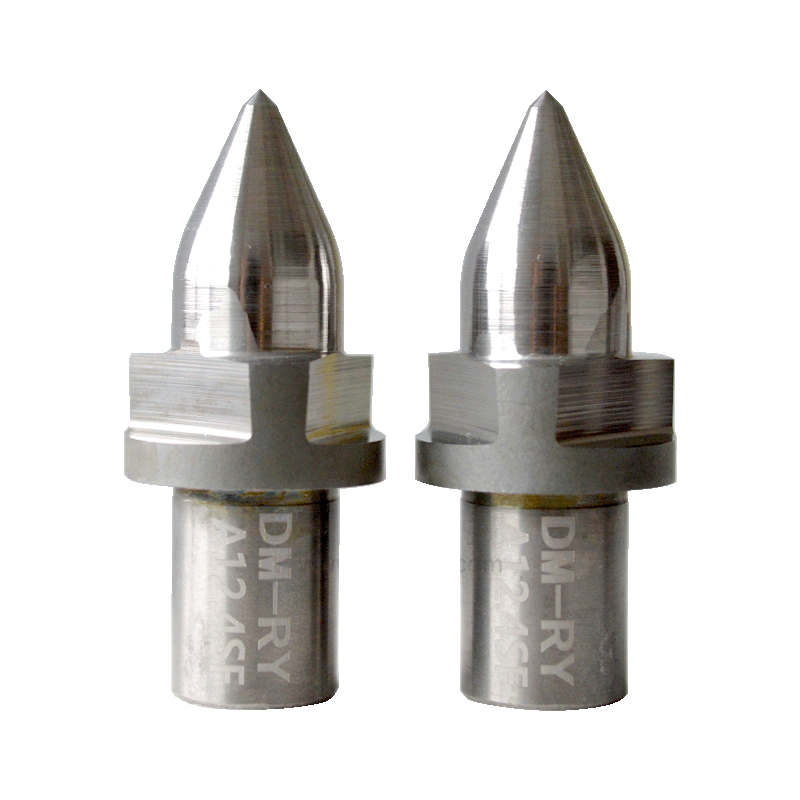

A friction drill bit, also known as a thermal drilling bit or heat friction bit, is a conical, high-speed rotating tool made of wear-resistant materials such as tungsten carbide. It generates intense frictional heat upon contact with a metal surface, softening and displacing the material to form a hole along with an extruded collar or bushing. This process enables strong, threadable connections in metals as thin as 1.0 mm, making it an ideal solution for automotive, electric vehicle (EV), furniture, and HVAC manufacturing industries.

Key Features of Friction Drill Bits:

Chipless operation (no metal shavings)

Integrated bushing formation for threading

Applicable to steel, stainless steel, aluminum, brass, and copper

Fast cycle times ideal for automated production

No pre-drilling or post-welding required

DUOMI Friction Drill Bits: Industrial-Grade Performance

DUOMI, a leading CNC machinery and tooling manufacturer in China, specializes in friction drilling technology and offers a wide range of high-performance thermal friction drill bits. These bits are designed for heavy-duty, continuous-use operations and are trusted by manufacturers worldwide for their longevity, accuracy, and versatility.

Advantages of DUOMI Friction Drill Bits

1. High Wear Resistance

DUOMI friction drill bits are manufactured using premium-grade tungsten carbide alloy, providing exceptional resistance to heat, deformation, and wear. This ensures a longer service life even under extreme production conditions.

2. Precision Engineering

Each drill bit is CNC-ground with micron-level accuracy, ensuring perfect concentricity and smooth bushing formation. The precision-engineered tip geometry enables consistent performance across a variety of metals and wall thicknesses.

3. Efficient Heat Transfer

DUOMI drill bits are designed to optimize frictional heat concentration at the point of contact. This allows for rapid penetration and bushing formation without overheating or distorting the surrounding material.

4. Compatibility with CNC and Manual Machines

DUOMI thermal drill bits are compatible with both fully automated CNC friction drilling machines and manual or semi-automatic drilling stations, making them suitable for small workshops and large-scale production lines alike.

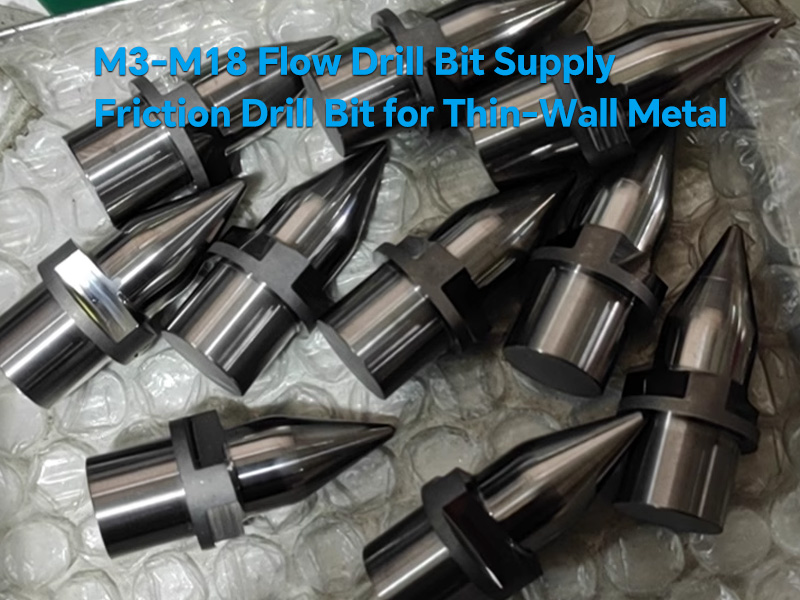

5. Broad Size Range and Customization

Available in standard diameters from 2.5 mm to 20 mm, DUOMI also offers custom-size friction drill bits tailored to specific project requirements or frame geometries.

6. Ideal for Thin-Walled Tubing

Whether working with electric vehicle battery enclosures, bicycle frames, or furniture tubing, DUOMI drill bits enable secure, threadable holes in materials as thin as 1.0 mm, eliminating the need for additional inserts or welding.

Common Applications

DUOMI friction drill bits are widely used in:

Motorcycle and EV frame manufacturing

Furniture assembly (steel/aluminum tubes)

Fitness equipment

HVAC ducting systems

Display racks and retail fixtures

Electrical enclosures and battery modules

Environmental and Cost Benefits

No chips or coolant required – reduces waste and cleanup

Fewer secondary processes – no tapping inserts or welding needed

Lower material cost – eliminates need for thicker metal or reinforcement

Higher productivity – rapid hole formation and automation-ready

Why Choose DUOMI?

With a strong commitment to precision tooling and thermal drilling innovation, DUOMI has established itself as a reliable partner for manufacturers seeking efficient, high-quality drilling solutions. The company provides:

Fast global shipping and OEM support

Professional technical consultation

Competitive pricing without compromising on quality

Ongoing R&D to meet evolving industry standards

Conclusion

The friction drill bit is transforming how modern industries approach hole-forming in thin-walled metals, offering a cleaner, faster, and stronger alternative to traditional methods. With DUOMI's high-performance thermal drilling bits, manufacturers gain a competitive edge in product strength, assembly speed, and operational efficiency. Whether you're producing electric vehicle frames, industrial furniture, or steel structures, DUOMI friction drill bits deliver the strength you need—without the compromise.

Keywords: friction drill bit, thermal drilling bit, chipless drilling, DUOMI drill bit, heat friction drilling, tube threading without welding, CNC friction drill, motorcycle frame drilling, EV frame tooling, thin wall metal hole forming.