Application of Thermal Friction Drilling Machines in Motorcycle and Electric Vehicle Frames Introduction

As the global demand for lightweight, high-strength mobility solutions continues to rise, manufacturers of motorcycles and electric vehicles (EVs) are under increasing pressure to improve production efficiency, material utilization, and frame durability. Traditional hole-making and joining methods—such as drilling followed by welding or rivet insertion—often compromise the structural integrity of thin-walled metal tubes used in vehicle frames. In this context, thermal friction drilling machines (also known as friction-based thermal drilling systems) are emerging as a game-changing solution. By leveraging heat and rotational force instead of material removal, these machines create clean, high-strength holes and form internal bushings ideal for threading—without damaging or weakening the parent metal.

What is Thermal Friction Drilling?

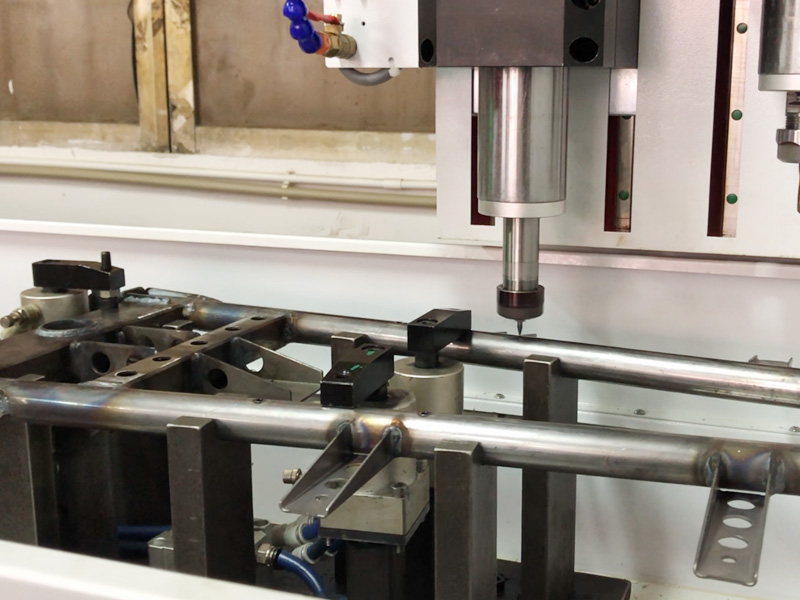

Thermal friction drilling is a non-cutting hole-forming technique that uses a high-speed rotating, conical, heat-resistant tool to penetrate metal surfaces through friction-generated heat. This process plastically deforms the material rather than removing it, creating a bushing (or collar) on the exit side of the hole. The extruded bushing can then be tapped to produce a robust internal thread, even in thin-walled tubing where traditional threading is infeasible.

Key characteristics of thermal friction drilling:

No chip production (chipless operation)

Stronger threaded connections

Minimal material distortion

Applicable to ferrous and non-ferrous metals

Excellent repeatability for automated production lines

Relevance in Motorcycle and EV Frame Manufacturing

Motorcycle and electric vehicle frames are typically constructed from steel, stainless steel, or lightweight aluminum tubes with wall thicknesses between 1.0 mm and 3.0 mm. Conventional drilling and tapping processes in such thin-walled structures often result in insufficient thread engagement or weak joints, necessitating the use of welded nuts, inserts, or brackets.

Thermal friction drilling eliminates these drawbacks by creating integrated bushings suitable for direct threading. This not only enhances joint reliability but also reduces parts count, assembly time, and production costs.

Key Advantages in Frame Applications:

Enhanced Joint Strength

The extruded bushing formed during friction drilling provides 3–5 times more thread engagement length compared to conventional drilled holes. This is particularly valuable in vibration-prone environments like motorcycles and electric scooters.

Material Efficiency

There is no material wastage as the process reshapes existing metal rather than removing it. This is critical for lightweight vehicle design, where every gram matters.

Simplified Production Workflow

Eliminates the need for secondary components (nuts, inserts, or brackets) and reduces the number of welding points, thus simplifying the production line and reducing labor intensity.

Improved Aesthetic and Structural Integrity

With fewer external welds and brackets, the frame maintains a cleaner look and improved aerodynamics while reducing the risk of corrosion and mechanical failure at weld points.

Adaptability to Automation

Thermal friction drilling machines are compatible with robotic arms and CNC systems, enabling seamless integration into automated manufacturing lines—a growing trend in EV production plants.

Application Scenarios in Motorcycle and EV Frames

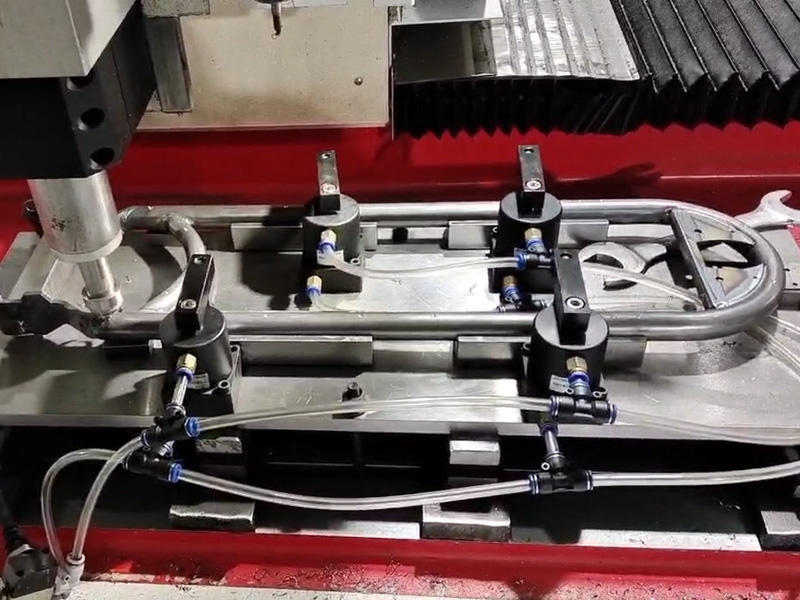

1. Mounting Points for Foot Pegs and Battery Holders

Many foot pegs, engine guards, and battery casings require firm anchoring onto tubular frames. Friction drilling enables direct threading into the frame tube, providing a secure, long-lasting hold without external fasteners.

2. Assembly of Accessory Mounts

Headlight brackets, luggage racks, and fairing attachments can be mounted using thermally drilled threaded holes, reducing reliance on clamped joints or welded brackets.

3. Suspension and Steering Column Integration

In electric motorcycles and scooters, the front fork assembly and steering column mounts benefit from precise, high-strength connections. Thermal drilling ensures consistent dimensional tolerances and uniform mechanical properties at these critical points.

4. Battery Management System (BMS) Integration

Many EVs integrate the BMS and battery enclosures directly into the frame. Thermal friction drilling allows safe, accurate, and efficient creation of multiple mounting holes for BMS modules or cooling plates, even in confined tube sections.

Material Compatibility

Thermal friction drilling can be applied to a wide range of materials commonly used in motorcycle and EV frames:

Mild Steel: High strength with good machinability

Stainless Steel: Corrosion-resistant and structurally durable

Aluminum Alloys: Lightweight and widely used in electric scooter frames

Copper or Brass (in specific BMS or electrical mounting areas)

The selection of tool material (typically tungsten carbide or cobalt alloys) and process parameters such as rotational speed, feed rate, and lubrication are critical in achieving optimal results across different substrates.

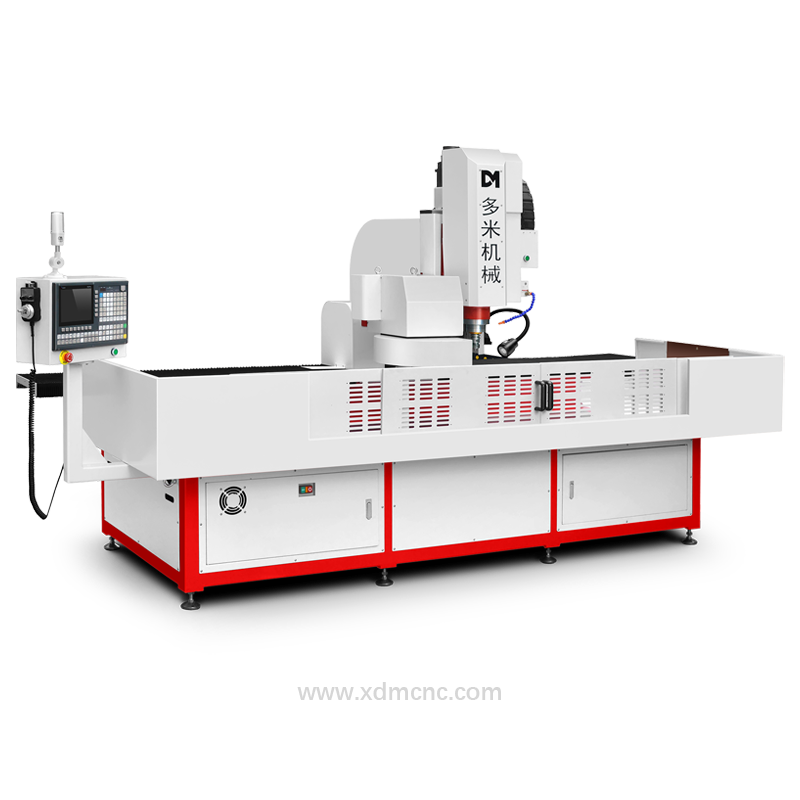

Integration into Modern Manufacturing

With the push towards Industry 4.0 and smart manufacturing, thermal friction drilling machines can be seamlessly integrated into CNC lines and robotic stations. Leading OEMs are adopting this technology not only for its precision but also for its scalability and adaptability to high-volume production demands.

For instance, a friction drilling system with servo-controlled feed and spindle speed can be programmed to drill and tap hundreds of holes across varying tube geometries in a single setup, ensuring consistency, accuracy, and minimal downtime.

Environmental and Economic Benefits

Lower Energy Consumption: Compared to welding or traditional tapping, thermal drilling is a low-energy process with minimal heat dissipation.

No Coolant Waste: Most machines operate with minimal or no cutting fluid, reducing environmental impact and maintenance costs.

Fewer Components and Logistics: Removing the need for nuts, washers, or inserts simplifies inventory management and reduces overall BOM (bill of materials) complexity.

Future Outlook

As electric mobility continues to evolve, frame designs are becoming more integrated, multifunctional, and structurally optimized. Thermal friction drilling will likely play an increasingly important role in achieving these goals. New machine variants with multi-head drilling, real-time quality control sensors, and adaptive control algorithms are already being developed to meet the sophisticated needs of next-generation vehicle manufacturing.

Conclusion

Thermal friction drilling machines offer a transformative approach to joining and assembly in motorcycle and electric vehicle frame production. By enabling precise, strong, and clean threaded holes directly in thin-walled tubes, they address key challenges in structural design, manufacturing efficiency, and cost control. As more manufacturers shift towards lightweight, durable, and eco-friendly solutions, thermal friction drilling stands out as a forward-thinking technology ready to meet the demands of tomorrow’s mobility industry.