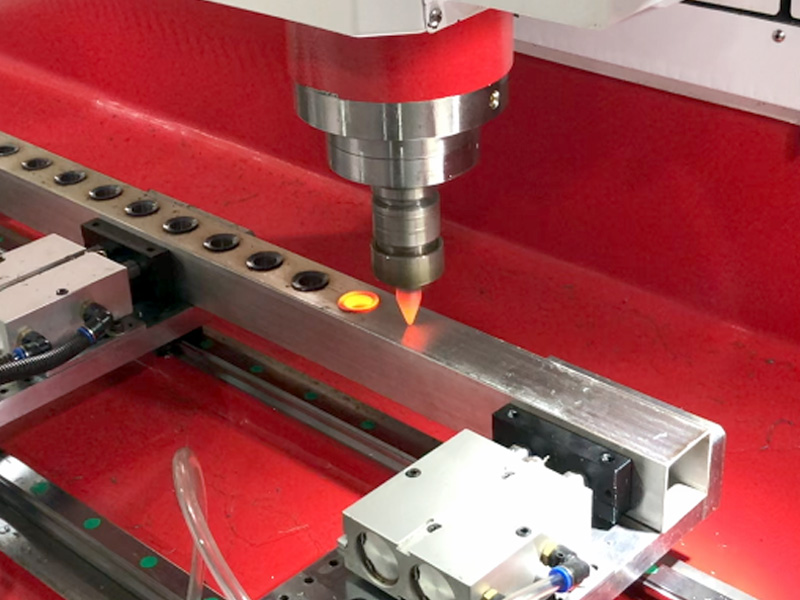

Thermal Drilling and Threading Performance on Metal Square Tubes

In the world of metal fabrication, precision and efficiency are crucial. For manufacturers working with metal square tubes, achieving clean, strong threaded holes without damaging the tube structure is a constant challenge.

Thermal drilling and threading offer an advanced solution that significantly enhances fabrication quality and production speed.

What is Thermal Drilling?

Thermal drilling is a non-cutting, heat-based process that uses a specialized, high-speed drilling tool to soften and displace the material, forming a hole without removing metal.

Instead of creating chips like traditional drilling, the tool generates frictional heat to plasticize the metal, pushing it outward and forming a strong, flared hole. This process is ideal for thin-walled metal tubes where conventional threading would be difficult or impossible.

Advantages of Thermal Drilling on Metal Square Tubes

Stronger Threads:

Thermal drilling produces a formed collar around the hole, providing more material thickness for stronger thread engagement.

No Burrs, No Cracks:

The process creates smooth, burr-free holes with no risk of cracking or weakening the tube structure.

High-Speed Operation:

Thermal drilling and threading can be completed in seconds, dramatically improving production efficiency compared to traditional drilling and tapping.

Extended Tool Life:

Specially designed thermal drill bits are highly durable and can perform thousands of operations with minimal wear.

Environmentally Friendly:

Since no cutting chips are produced, there is less waste and minimal need for coolant fluids.

Applications Across Industries

Thermal drilling and threading on metal square tubes are widely used in:

Furniture manufacturing (frames, support structures)

Automotive components (chassis, brackets)

Fitness equipment (exercise machine frames)

Construction (metal frameworks, railings)

Display racks and shelving systems

In each case, the thermal process ensures secure, long-lasting threaded connections even in thin-walled materials.