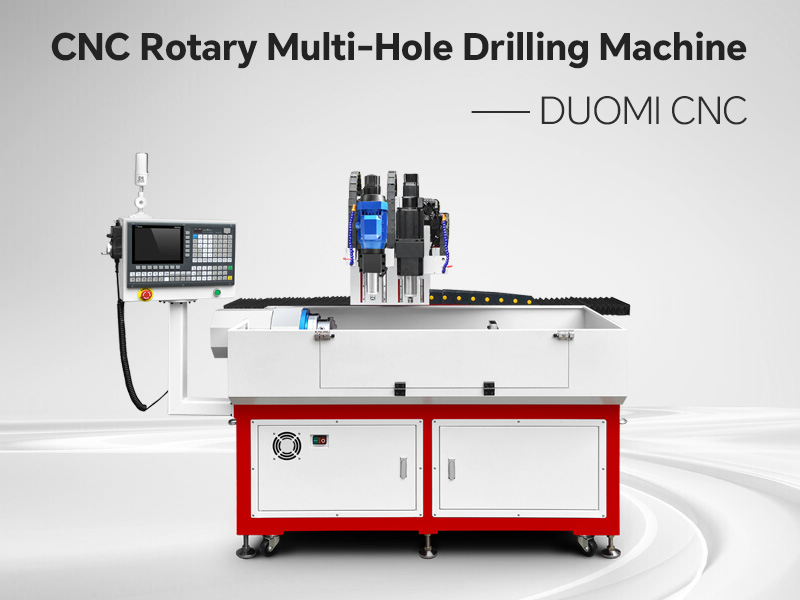

CNC Rotary Multi-Hole Drilling Machine for Round Aluminum Tubes: Unlock Precision and Efficiency

In today's fast-paced manufacturing environment, precision, speed, and consistency are critical factors for success. Particularly in industries that rely heavily on aluminum structures — such as automotive, aerospace, construction, and furniture manufacturing — the need for efficient drilling solutions has never been greater.

That's where the CNC Rotary Multi-Hole Drilling Machine for Round Aluminum Tubes steps in.

This innovative system redefines aluminum tube fabrication, combining CNC automation, rotary positioning, and multi-hole drilling capabilities to deliver unparalleled performance.

What is a CNC Rotary Multi-Hole Drilling Machine?

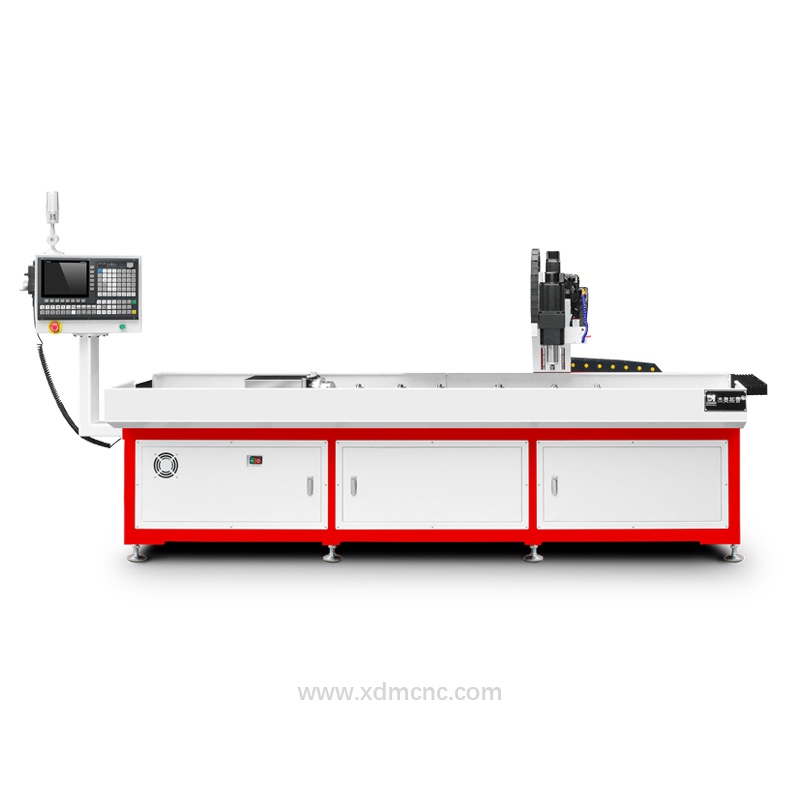

A CNC Rotary Multi-Hole Drilling Machine is a computer-controlled device designed to drill multiple precision holes in round aluminum tubes.

The machine automatically rotates the tube to designated angles, enabling efficient drilling operations on various sides without manual repositioning.

By combining rotary movement and multi-hole drilling heads, this system dramatically increases production speed and ensures uniform accuracy across all drilled parts.

Key Features and Advantages

1. High Precision Drilling

Equipped with CNC programming and rotary indexing, the machine ensures every hole is placed exactly where it’s needed, maintaining tight tolerances for high-quality assembly and welding processes.

2. Multi-Hole Efficiency

Instead of repositioning the tube manually for each hole, multiple holes are drilled simultaneously or in quick succession, saving valuable time and reducing labor costs.

3. Rotary Tube Handling

The rotary axis allows 360° tube rotation, enabling drilling at various angles around the tube’s circumference — perfect for complex fabrication requirements.

4. Versatile Tube Size Compatibility

Our CNC rotary drilling systems accommodate a wide range of tube diameters and wall thicknesses, from small precision tubes to large structural aluminum pipes.

5. User-Friendly CNC Control

Operators can easily set up hole patterns, drilling depths, rotation angles, and sequences via a simple touchscreen interface, reducing operator error and setup time.

6. Minimal Material Waste

Precision drilling ensures clean hole formation without damaging the surrounding structure, maximizing material usage and maintaining the tube's integrity.

Applications Across Industries

The CNC Rotary Multi-Hole Drilling Machine serves a wide array of industries where aluminum tubes are essential:

Automotive: Frame components, exhaust systems, roll cages.

Furniture Manufacturing: Aluminum chairs, tables, shelving units.

Construction: Structural supports, curtain wall frames, railings.

Fitness Equipment: Gym frames, exercise machines, bicycle frames.

Aerospace: Lightweight structural tubing for aircraft interiors and exteriors.

In each application, precise and consistent drilling is critical to ensuring structural strength, aesthetic appeal, and long-term durability.