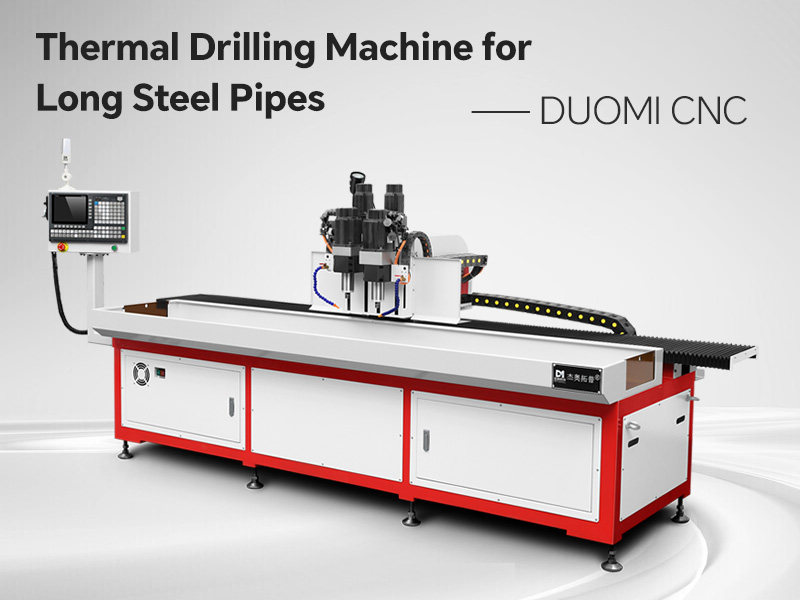

Thermal Drilling Machine for Long Steel Pipes: Boosting Efficiency in Modern Metalworking

In today's fast-paced industrial environment, precision, durability, and efficiency are critical factors for success. When it comes to creating high-quality threaded holes in long steel pipes, traditional drilling methods often fall short. This is where the Thermal Drilling Machine for Long Steel Pipes comes into play, offering a superior alternative that reshapes how industries approach metalworking.

What is a Thermal Drilling Machine?

A Thermal Drilling Machine uses heat and friction to form holes in metal instead of cutting through it. Unlike conventional drilling that removes material, thermal drilling displaces the material, creating a strong, formed hole with an integrated bush. This method significantly strengthens the joint area and eliminates the need for additional welding or inserts.

For long steel pipes, which are commonly used in industries like construction, furniture manufacturing, automotive, and fitness equipment, thermal drilling provides unmatched reliability and performance.

Key Advantages of Thermal Drilling for Long Steel Pipes

1. Increased Structural Strength

Thermal drilling enhances the strength around the drilled area by forming a collar or sleeve from the base material itself. This is crucial for long steel pipes, where maintaining the pipe’s structural integrity is essential.

2. Cleaner and Faster Operations

Unlike traditional drilling that creates chips and debris, thermal drilling produces minimal waste. The process is cleaner, faster, and significantly reduces the need for post-processing.

3. Extended Tool Life

Because thermal drilling uses controlled heat and pressure rather than sharp cutting edges, the wear and tear on tooling is greatly reduced. This translates into lower maintenance costs and fewer machine downtimes.

4. Suitable for Various Pipe Thicknesses

Whether dealing with thin-walled tubes or thicker pipes, a thermal drilling machine can easily adapt, offering flexibility across different production needs.

5. Perfect for Automation

Thermal drilling is highly compatible with CNC systems, making it ideal for automated production lines where consistent quality and speed are paramount.

Applications of Thermal Drilling in Long Steel Pipes

The Thermal Drilling Machine for Long Steel Pipes finds wide applications across multiple industries:

Construction: Creating strong, threaded holes for structural supports, scaffolding, and frameworks.

Furniture Manufacturing: Building durable metal frames for office furniture, chairs, and storage racks.

Automotive Industry: Producing reliable and high-precision parts for vehicle chassis and exhaust systems.

Fitness Equipment Production: Assembling robust gym machines and workout structures.

Oil and Gas Sector: Fabricating pipelines and structural supports with reinforced holes.

How Does Thermal Drilling Work?

The process of thermal drilling involves a specially designed, heat-resistant tool called a thermal drill bit. When the drill bit rotates at high speed and presses against the metal surface, it generates frictional heat. This heat softens the metal, allowing the tool to push through and form a hole while reshaping the surrounding material into a sleeve. This sleeve can then be tapped to create threads or left as a reinforced hole for bolts and screws.

The entire operation is typically completed in seconds, offering incredible efficiency for high-volume production lines.

Why Choose a Thermal Drilling Machine for Long Steel Pipes?

When it comes to manufacturing or fabrication involving long steel pipes, traditional methods like manual drilling and welding often fall short due to the following reasons:

Higher Risk of Material Damage: Traditional drilling can weaken thin-walled pipes.

Time-Consuming: Additional steps like cleaning chips and reinforcing holes are needed.

Higher Operational Costs: More tooling changes, frequent maintenance, and slower cycle times.

Investing in a Thermal Drilling Machine for Long Steel Pipes addresses all these challenges, ensuring:

Stronger joints

Lower production costs

Faster turnaround times

Greater product reliability

Thermal Drilling Machine for Long Steel Pipes

Thermal Drilling Machine

Long Steel Pipe Drilling Machine

Pipe Thermal Drilling Equipment

Thermal Drilling Technology for Steel Pipes

CNC Thermal Drilling Machine

Thermal Drilling for Metal Fabrication

High-Speed Thermal Drilling Machine

Tips for Choosing the Right Thermal Drilling Machine

When selecting a machine, consider the following factors:

Pipe Material and Thickness: Ensure the machine can handle your specific pipe dimensions.

Production Volume: Choose a model that matches your operational needs, whether for batch production or continuous flow.

Automation Capability: For maximum efficiency, opt for machines that integrate seamlessly with CNC systems.

After-Sales Support: Select a supplier who offers strong technical support, spare parts availability, and training.

Conclusion

The Thermal Drilling Machine for Long Steel Pipes is revolutionizing the way industries handle metal fabrication. By combining speed, strength, and precision, it offers a smarter, more cost-effective alternative to traditional drilling and welding methods.

Whether you’re producing components for construction, automotive parts, fitness equipment, or any other metal-based product, investing in thermal drilling technology can dramatically enhance your output quality and operational efficiency.

Ready to take your production capabilities to the next level? Contact us today to learn more about our advanced thermal drilling solutions!