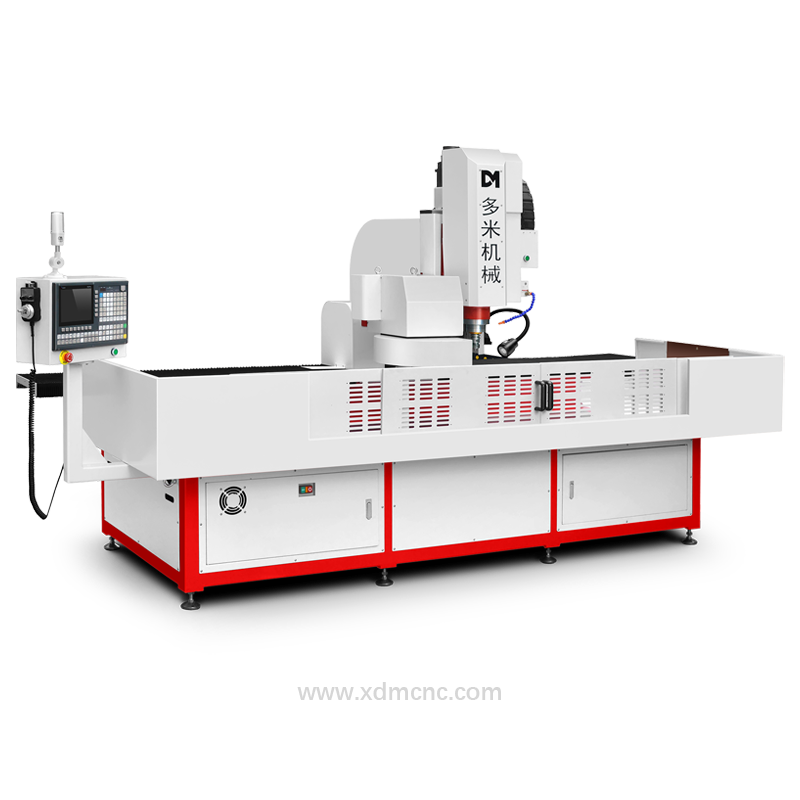

A mechanical frame thermal drilling & tapping machine is a CNC equipment designed specifically for thermal drilling and tapping on structural frame materials such as steel pipes, aluminum profiles, square tubes, and rectangular tubes. This type of machine is widely used in manufacturing mechanical frame structures that require high-strength connections, such as automation equipment frames, industrial workstations, conveyor systems, and steel structures.

Features & Advantages

Suitable for Various Frame Materials – Capable of processing carbon steel, stainless steel, aluminum alloys, and other metals.

High Efficiency & Stability – The thermal drilling technology enables hole drilling, forming, and tapping in a single step, significantly improving production efficiency.

Chip-Free Processing – Utilizes friction heat to soften and penetrate the metal, eliminating traditional cutting waste and improving material utilization.

Enhanced Thread Strength – The holes formed by thermal drilling have thickened walls, providing stronger thread engagement and more reliable connections.

Automated CNC Control – Ensures precise control of hole position, depth, and tapping process, improving machining consistency.

Application Industries

Automation Equipment Frames – Such as assembly line frames, robotic stands, etc.

Steel Structure Engineering – Processing of connecting components for modular steel structures.

Transportation Equipment – Used in the manufacturing of railings, guardrails, vehicle frames, etc.

Furniture Manufacturing – Metal frame tables, chairs, shelves, and other furniture structures.