A stainless steel tube thermal drilling machine is an advanced CNC machine used for drilling and tapping holes in stainless steel tubes. It utilizes a friction-based thermal drilling process to create high-precision holes with reinforced bushings. This innovative method eliminates the need for welding or additional fastening components, making it an efficient and cost-effective solution for various industries.

How Does Thermal Drilling Work?

Thermal drilling, also known as flow drilling, is a non-traditional drilling technique that relies on high-speed rotational friction to generate heat. The heat softens the stainless steel, allowing a specially designed carbide drill bit to penetrate and reshape the metal, forming a clean and durable hole with a built-in bushing.

Step-by-Step Process:

Friction Heat Generation – The rotating drill bit presses against the stainless steel surface, producing intense heat through friction.

Material Softening – The metal reaches a plasticized state, allowing it to be reshaped instead of being removed as chips.

Hole Formation – The drill bit pushes through the softened material, forming an extended bushing around the hole.

Threading (Optional) – The hole can be threaded immediately without requiring inserts or welding, improving mechanical strength.

Technical Advantages of Stainless Steel Tube Thermal Drilling

Stronger and More Durable Joints

The process creates a reinforced bushing, enhancing the strength and load-bearing capacity of the hole.

Burr-Free and Precise Drilling

Unlike conventional drilling, thermal drilling leaves smooth, clean, and precisely formed holes without burrs.

Material and Cost Savings

Eliminates the need for additional nuts, bolts, or welded reinforcements, reducing material and labor costs.

High-Speed and Efficient Process

Thermal drilling is significantly faster than traditional drilling and welding methods, boosting production efficiency.

Environmentally Friendly

Since there is minimal material waste, it is a sustainable manufacturing technique that reduces scrap production.

Applications of Stainless Steel Tube Thermal Drilling Machines

Automotive Industry – Used in exhaust systems, chassis frames, and precision tubing.

Construction & Infrastructure – Ideal for stainless steel railings, support structures, and prefabricated frameworks.

Aerospace & Defense – Provides high-strength hole formation for aircraft and military applications.

Furniture Manufacturing – Enhances the strength of stainless steel furniture frames and fixtures.

Choosing the Right Stainless Steel Tube Thermal Drilling Machine

When selecting a stainless steel tube thermal drilling machine, consider the following key factors:

Material Compatibility – Ensure the machine is designed to handle different stainless steel grades (e.g., 304, 316,49# duplex).

Precision & Automation – CNC-controlled machines offer higher accuracy and repeatability for mass production.

Cooling & Lubrication System – Proper cooling prevents excessive heat buildup and extends tool life.

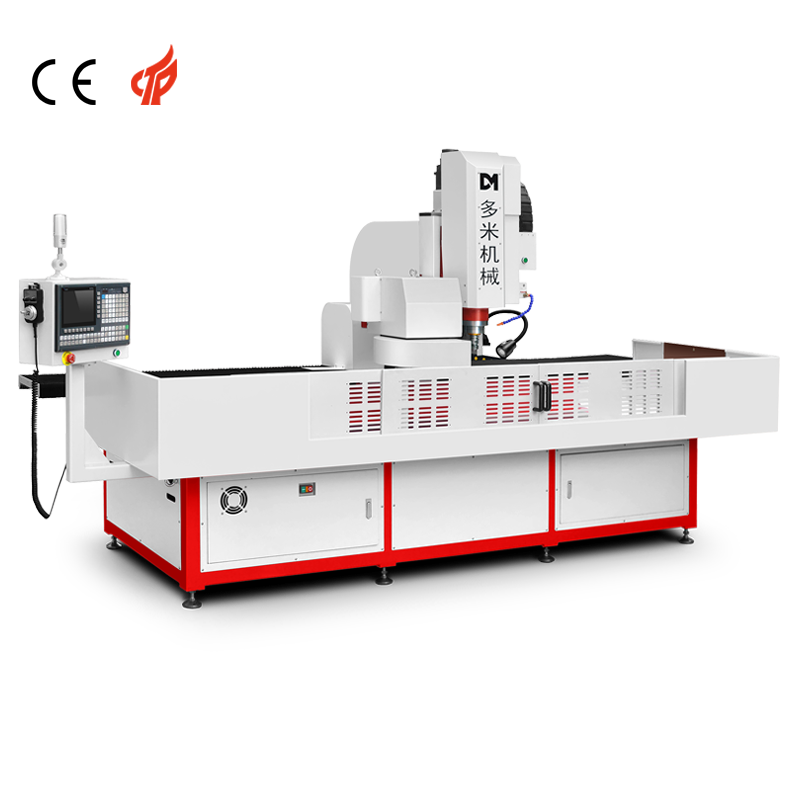

Brand & Support – Choose a reputable manufacturer like DUOMI CNC for reliable performance and after-sales service.

Conclusion

A stainless steel tube thermal drilling machine is a game-changer for industries requiring high-precision and durable hole formation in stainless steel tubes. Its ability to create reinforced, burr-free holes without additional fasteners makes it a cost-effective and efficient choice for modern manufacturing.

For more information, visit DUOMI CNC at www.xdmcnc.com and explore our high-performance CNC thermal drilling solutions.