Manufacturing Demand Behind the Project

In modern metal fabrication workshops, production efficiency is increasingly determined by how many machining steps can be completed in one setup. The customer involved in this project specializes in producing metal frames and tubular components used in industrial structures and mechanical assemblies. Their typical products require multiple threaded holes arranged along the same surface of big workpieces.

The four-spindle horizontal CNC drilling and tapping machine has been successfully put into operation at the customer's production facility

Previously, their machining process relied on repositioning the part several times for drilling and tapping. Although workable, this method caused frequent alignment errors and limited daily output. To address these issues, the customer began searching for equipment capable of processing multiple holes in one cycle while maintaining stable accuracy.

After evaluating several options, the customer selected a four-spindle horizontal drilling and tapping machine configured for long profiles and tubular parts. The main goal was to simplify positioning steps and improve consistency across batch production.

Machine Configuration for Workshop Conditions

Unlike standard vertical machines, the selected four-spindle horizontal drilling and tapping machine was designed to accommodate big workpieces with side-surface machining requirements. The horizontal layout allows the material to remain well supported during processing, reducing bending or vibration during cutting.

The machine was configured with:

A synchronized four-spindle unit

A rigid horizontal worktable

Independent feed control for drilling and tapping

Integrated coolant and chip evacuation system

This configuration enables several holes to be drilled and tapped at the same time, which shortens the machining cycle and improves repeatability. Before shipment, the system was tuned according to the customer's material type and hole specifications.

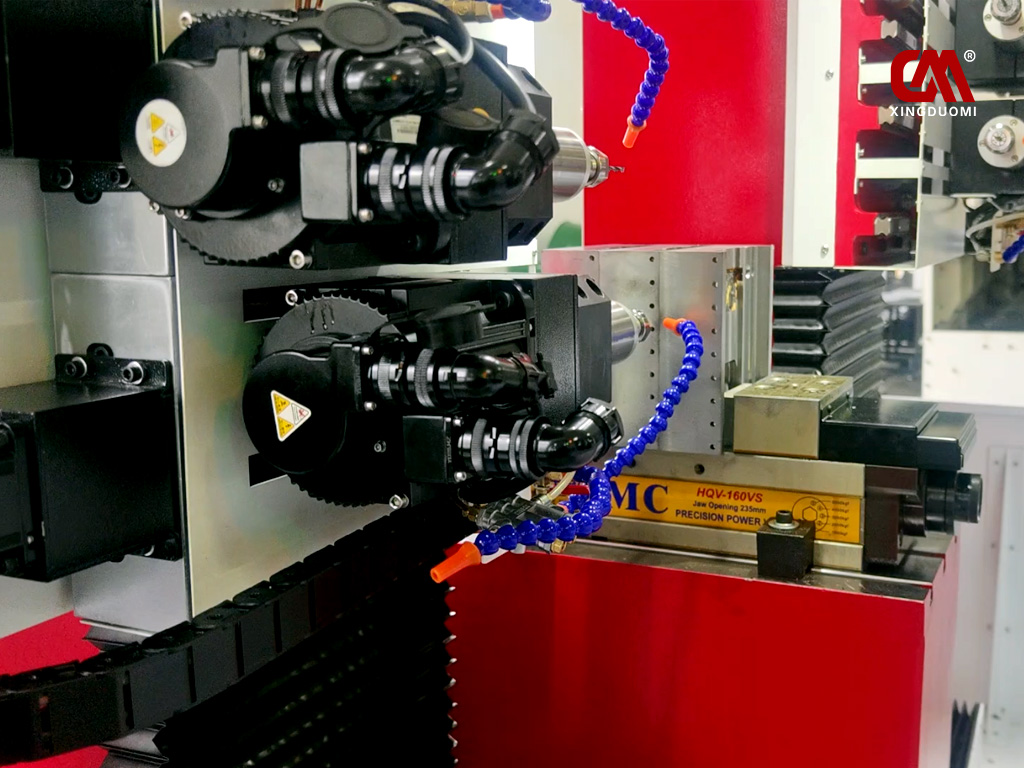

The four-spindle horizontal CNC drilling and tapping machine is currently machining metal components

Delivery and Workshop Integration

Once factory inspection was completed, the machine was transported to the customer's production facility. The workshop layout had already been prepared with a dedicated space for the new equipment.

Installation involved:

Positioning the machine parallel to the material feeding area

Securing the machine base and verifying level accuracy

Connecting electrical and pneumatic systems

Aligning the spindle unit with the fixture system

After installation, the control panel and safety components were checked. At this stage, the four-spindle horizontal drilling and tapping machine became part of the customer's regular production environment rather than a standalone test unit.

Trial Machining with Real Production Parts

Instead of using sample pieces, the customer chose to test the machine with actual production components. These were big rectangular steel tubes with evenly spaced threaded holes.

The machining process followed a simple workflow:

Material loading and clamping

Program selection

Simultaneous drilling and tapping

Automatic tool retraction

By using a single setup for multiple hole positions, the machine reduced the need for manual adjustment. The four-spindle horizontal drilling and tapping machine completed each workpiece in one cycle, while the operator focused mainly on material handling.

Initial inspection showed that hole spacing and thread depth met the customer's tolerance requirements. This confirmed that the machine could handle real production tasks rather than demonstration samples.

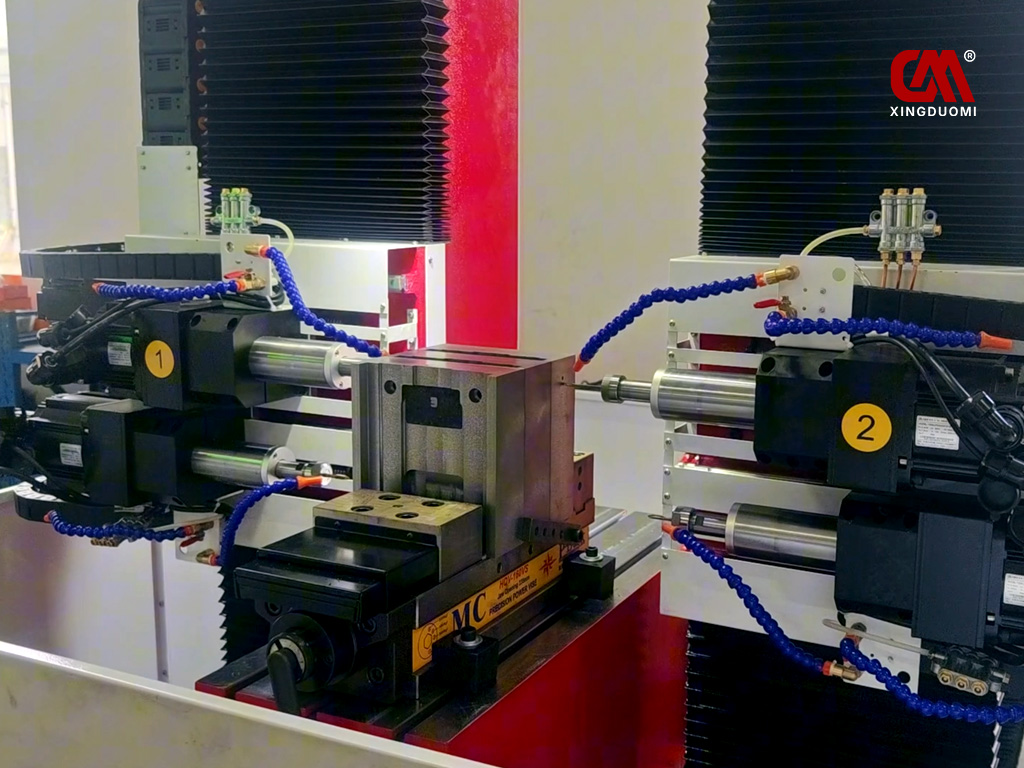

The four-spindle horizontal CNC drilling and tapping machine is simultaneously machining three metal products

Productivity Changes Observed on Site

After several hours of continuous operation, production supervisors compared the new results with the previous workflow. Three main differences were recorded:

Shorter Processing Time per Part

Multiple drilling and tapping actions were completed at once, eliminating repeated positioning.

Lower Operator Intervention

The operator no longer needed to realign the workpiece after each hole group, which reduced handling errors.

More Predictable Output

Cycle times became consistent, making it easier to plan daily production schedules.

These improvements demonstrated that the four-spindle horizontal drilling and tapping machine directly influenced both efficiency and planning accuracy.

Application Value for Structural Components

The customer's products are widely used in support frames and mechanical assemblies. In such applications, uniform hole position is critical for downstream welding or bolting.

With the introduction of the four-spindle horizontal drilling and tapping machine, the machining process became more standardized. Each part followed the same program path, ensuring that hole positions matched design drawings without manual compensation.

This consistency reduced rework and minimized material waste, which is especially important when processing big steel or aluminum profiles.

Training and Daily Operation Setup

Once stable operation was confirmed, on-site training was conducted for operators and maintenance staff. The training focused on:

Startup and shutdown procedures

Tool alignment and replacement

Program selection and modification

Routine inspection points

Within a short period, operators were able to independently manage the four-spindle horizontal drilling and tapping machine. Daily operation was then integrated into the existing shift schedule without disrupting other equipment.

This smooth transition reduced downtime and ensured that production targets could be met without extended adjustment periods.

Maintenance and Long-Term Stability

For long-term use, the customer paid particular attention to maintenance planning. The machine was added to their routine inspection list, including:

Lubrication of guide rails

Cleaning of chip removal channels

Checking spindle temperature and noise

Monitoring cutting tool wear

These measures are intended to preserve the working accuracy of the four-spindle horizontal drilling and tapping machine over extended production cycles.

Stable performance is especially important for batch manufacturing, where even small deviations can accumulate into larger quality issues.

Customer Assessment After Initial Production Period

After the first production batch was completed, the customer conducted an internal evaluation. Their main conclusions were:

The machine meets their output requirements

Hole quality remains consistent throughout big runs

Operators adapted quickly to the new process

Workshop layout did not require major modification

From a management perspective, the four-spindle horizontal drilling and tapping machine simplified workflow control and improved predictability in production planning.

The Duomi four-spindle horizontal CNC drilling and tapping machine is currently performing batch machining of metal components

Significance for Modern Machining Workshops

This project illustrates how multi-spindle equipment can be integrated into real manufacturing conditions rather than isolated test environments. The shift from step-by-step processing to synchronized machining helps workshops handle higher order volumes without increasing labor input.

The four-spindle horizontal drilling and tapping machine offers a practical solution for factories that work with big workpieces and repetitive hole patterns. By reducing setup frequency, it lowers the risk of alignment errors and shortens production cycles.

Such improvements are increasingly relevant as customers demand shorter delivery times and more stable quality.

The delivery and commissioning of this four-spindle horizontal drilling and tapping machine represent a practical upgrade in the customer's machining process. From installation to full production, the machine demonstrated stable operation and measurable efficiency gains.

Rather than relying on theoretical performance data, this case shows actual workshop results using real production parts. The outcome confirms that multi-spindle horizontal machining can play a key role in modern manufacturing systems where accuracy and throughput must be balanced.

As production continues, the machine is expected to support higher output levels while maintaining consistent machining quality, becoming a central component of the customer's manufacturing line.