When it comes to heavy-duty drilling on tube sheets, boilers, heat exchangers, and condensers, traditional machining often struggles with accuracy, speed, and consistency. That's where a CNC tube sheet drilling machine makes the difference. With automation, precision, and incredible efficiency, it's transforming how global manufacturers handle large-scale drilling tasks. If you're looking for a solution that saves labor costs, improves accuracy, and maximizes throughput, DUOMI CNC is the name you can trust.

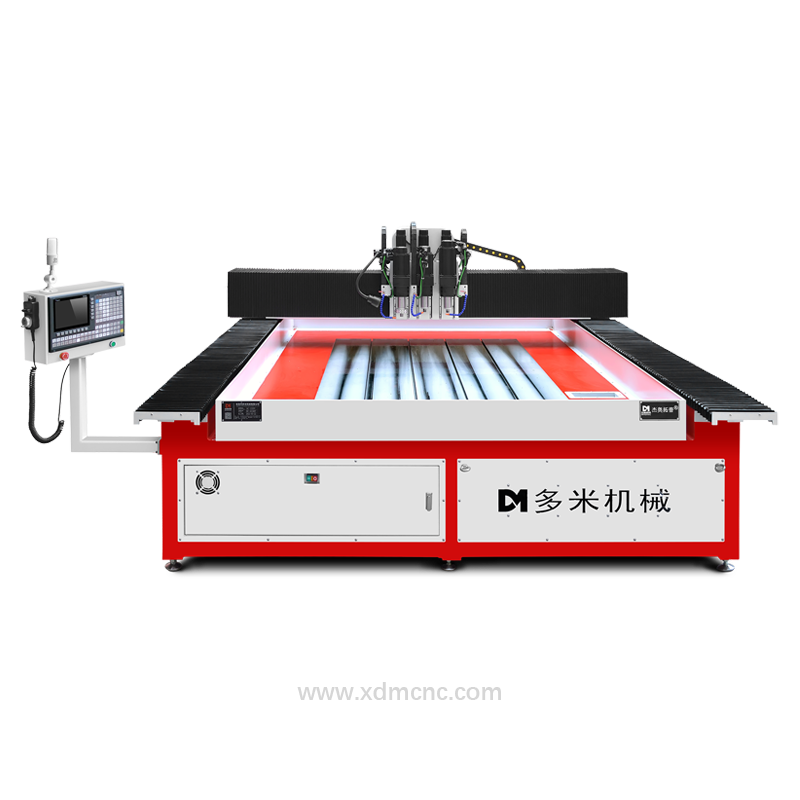

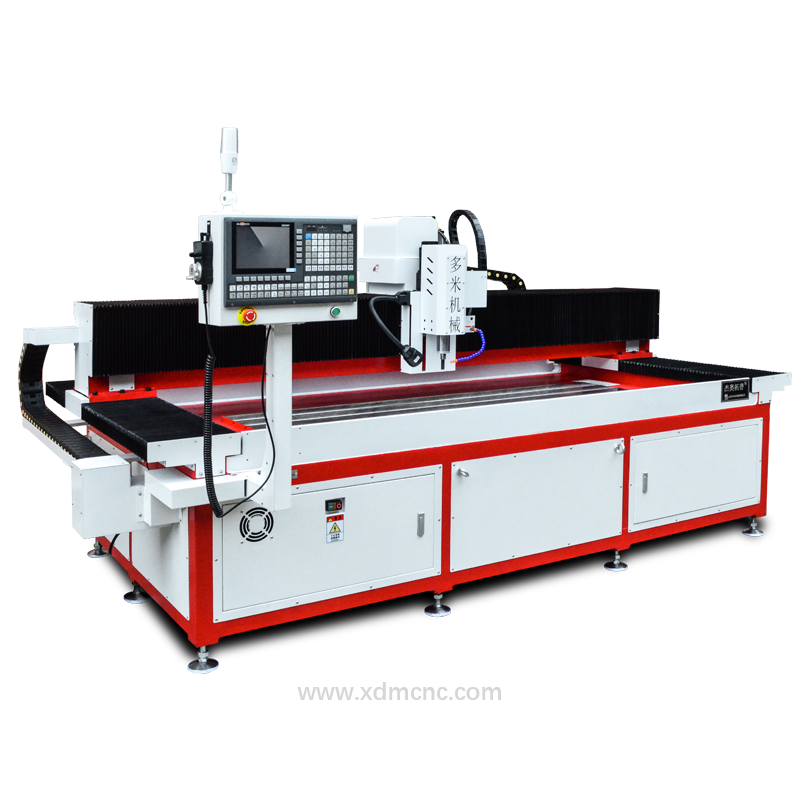

CNC Tube Sheet Drilling Machine

Why Choose a CNC Tube Sheet Drilling Machine?

A CNC tube sheet drilling machine is purpose-built to handle thick plates and multiple holes with pinpoint accuracy and repeatability. Unlike manual or semi-automatic drilling, this advanced system ensures:

Speed: Processes thousands of holes in a fraction of the time.

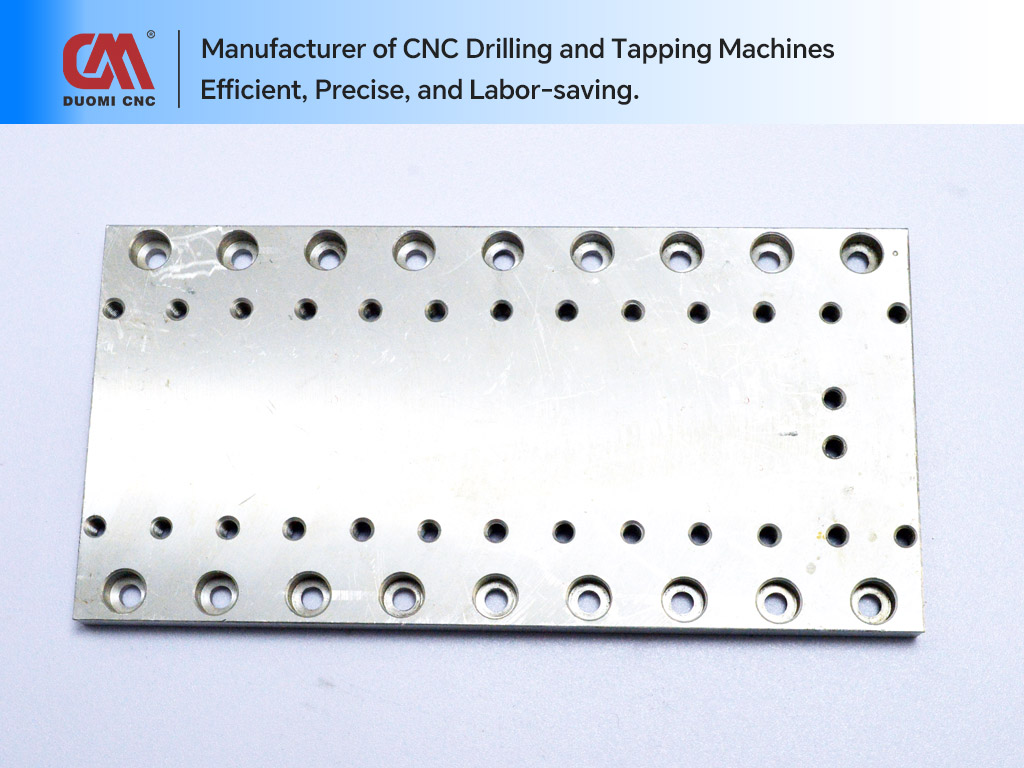

Accuracy: Precision up to 0.01mm, no matter how dense the hole pattern.

Durability: Built to work continuously without breakdowns.

Flexibility: Handles tube sheets, flanges, and heavy steel plates with ease.

For industries like petrochemical, power plants, shipbuilding, HVAC, and pressure vessel manufacturing, the CNC tube sheet drilling machine is not a luxury—it's a necessity.

CNC Tube Sheet Drilling Machine vs. Traditional Methods

Let's be honest—traditional drilling is time-consuming, labor-intensive, and error-prone. Operators often face issues like:

Misaligned holes → leading to wasted materials and rework.

Slow processing speed → projects take longer to deliver.

High labor dependency → skilled workers are costly and hard to find.

Fatigue and inconsistency → human error increases with time.

Condensers tubes thermal drilling

With a DUOMI CNC tube sheet drilling machine, you solve all these pain points in one shot. The machine works non-stop with consistent accuracy, reducing production time by up to 70%.

Key Features of DUOMI CNC Tube Sheet Drilling Machine

When you invest in DUOMI CNC, you don't just get a machine—you get a reliable partner in production. Here's what makes our equipment stand out:

1. High-Speed Precision

Spindle speeds reaching 8,000 RPM.

Perfect for micro holes or large-diameter tube holes.

2. Customizable Size & Travel

From 400mm small sheets to 13-meter long plates, each machine is tailored to your exact needs.

3. Easy-to-Use Interface

No programming background required.

Operators can be trained in just one day.

4. Multi-Spindle & Automatic Tool Changer

Cuts down cycle times drastically.

Allows uninterrupted drilling across different hole sizes.

5. Built for Longevity

Heavy-duty gantry design ensures stability and vibration-free performance.

CNC Drilling of Counterbores in Stainless Steel Plates

CNC Tube Sheet Drilling Machine Applications

Whether you're in power generation, oil & gas, HVAC, or marine engineering, tube sheet drilling is unavoidable. Here are some industries where DUOMI machines are game-changers:

Petrochemical plants: Tube sheets for heat exchangers.

Power plants: Drilling condenser plates.

Shipbuilding: Fabrication of boilers and cooling systems.

HVAC manufacturers: High-precision tube sheets for industrial systems.

Why DUOMI CNC Is Your Trusted Partner

DUOMI CNC isn't just another machine manufacturer. We're recognized globally for precision, durability, and customer-first service. Here's why our clients across the U.S., Europe, Middle East, and Asia keep coming back:

✅ Multiple Shipping Ports

We ship directly from Shanghai, Shenzhen, Qingdao, and Guangzhou, and we can also dispatch from any customer-designated port for maximum convenience.

✅ Fast Delivery & Quick Setup

With a streamlined logistics process, your machine arrives quickly, is installed in days, and is ready to run.

✅ Hassle-Free Warranty

Every DUOMI CNC tube sheet drilling machine comes with a worry-free warranty, ensuring smooth performance and immediate support when you need it.

✅ Around-the-Clock Support

Our 24/7 technical service team provides remote guidance and on-site training—so you're never left waiting.

Customer Success Stories

One of our clients in Germany's HVAC industry reported that after switching from traditional drilling to a DUOMI CNC tube sheet drilling machine, their production time dropped by 65% while accuracy improved beyond industry standards.

Another customer in Dubai's petrochemical sector praised how our multi-spindle design reduced their manpower requirements by half—boosting profits significantly.

Take Your Manufacturing to the Next Level

The global market is competitive, and efficiency is the key to staying ahead. With a DUOMI CNC tube sheet drilling machine, you're not just upgrading your production—you're future-proofing your business.

Ready to cut labor costs, improve precision, and deliver projects faster than ever?

Contact DUOMI CNC today and get a customized CNC solution tailored to your production needs.

Final Call-to-Action

With DUOMI CNC, you get unsurpassed quality, global delivery from China's top ports (Shanghai, Shenzhen, Qingdao, Guangzhou), and a warranty you can count on. Don't let outdated drilling hold your business back—upgrade to DUOMI CNC today and stay ahead of your competition.