In today's fast-paced manufacturing world, no shop can afford downtime, wasted labor, or inefficient equipment. That's why many forward-thinking businesses are upgrading to the double spindle drilling and tapping machine from DUOMI CNC. If you've ever felt the pain of slow, outdated equipment, this guide will open your eyes to what modern technology can do for your bottom line.

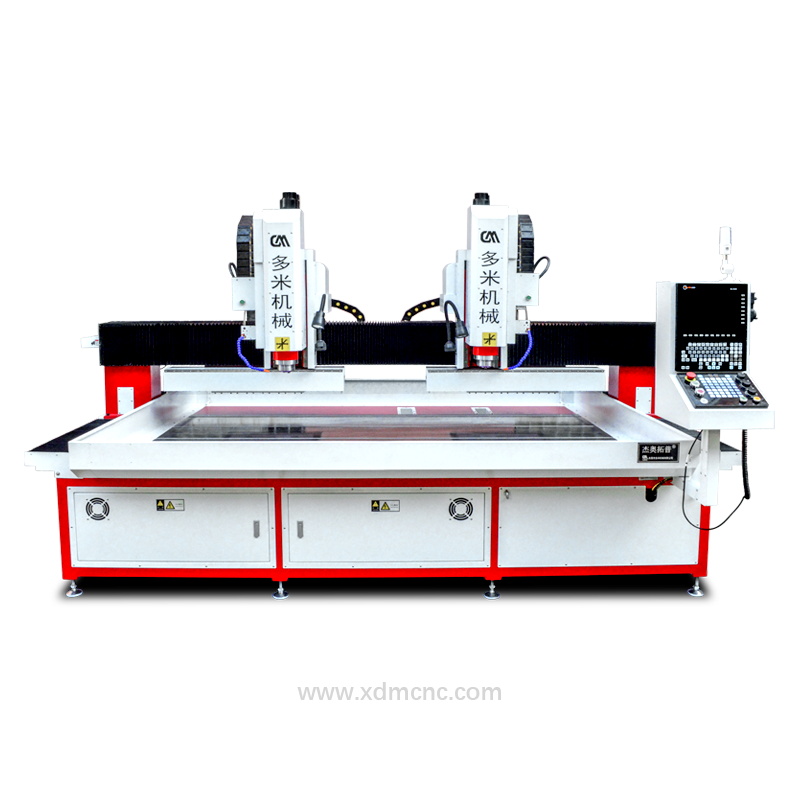

Double Spindle Drilling and Tapping Machine

Why Manufacturers Are Switching to Double Spindle Machines

Traditional single-spindle drilling and tapping setups have served the industry for decades. But let's be real—they're holding back productivity. Operators spend valuable time repositioning materials, cycle times drag on forever, and precision isn't always guaranteed.

A double spindle drilling and tapping machine solves these headaches by allowing two spindles to work simultaneously. That means:

Twice the holes drilled in half the time.

Synchronized tapping operations for consistent thread quality.

Reduced tool change downtime.

Perfect alignment for high-volume production.

For factories making components for furniture, automotive, aerospace, or fitness equipment, the efficiency gain is massive.

The Pain Points of Traditional Drilling & Tapping

Before exploring the advantages of a double spindle design, let's look at what shops struggle with every day when using conventional machines:

Long Production Cycles – Single-spindle machines simply can't keep up with today's demand.

Labor Dependency – Operators must constantly adjust, leading to higher labor costs.

Inconsistent Quality – Human error often results in uneven hole spacing or poor thread integrity.

Maintenance Headaches – Outdated machines break down often, costing money and time.

Limited Flexibility – Scaling up production with older technology is almost impossible.

Sound familiar? These issues eat into profits. That's why investing in a DUOMI CNC double spindle drilling and tapping machine is not just a smart move—it's necessary for survival in competitive markets.

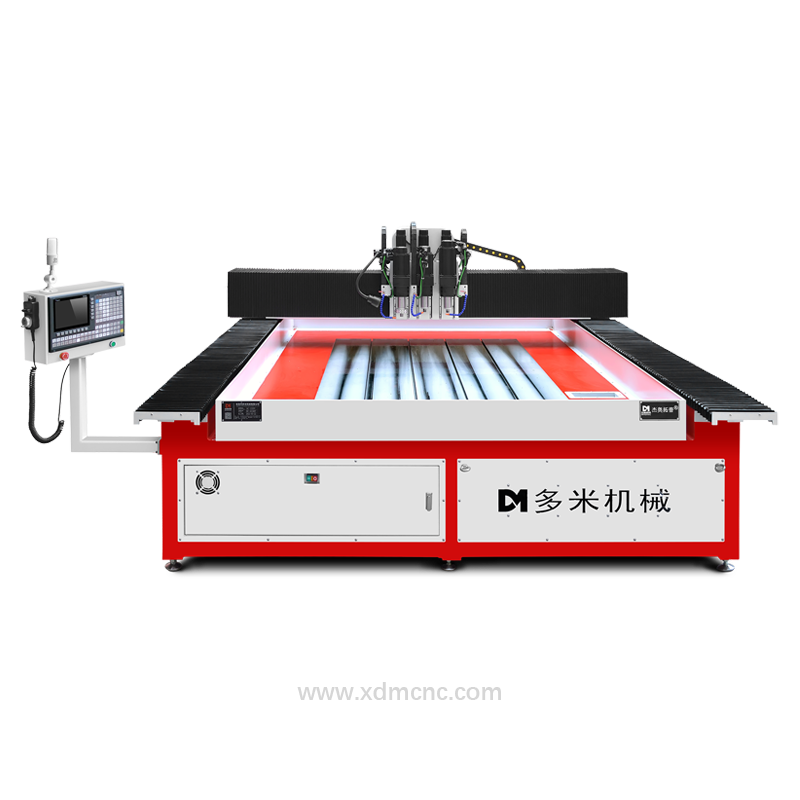

double spindle drilling and tapping machine for Multi-Hole Drilling in Stainless Steel Sheet Metal

Double Spindle Drilling and Tapping Machine – Game-Changing Features

When you choose DUOMI CNC, you're not just buying a machine; you're buying confidence, speed, and precision. Here's what makes our equipment stand out:

High-Speed Dual Spindle Operation

Both spindles run in parallel, dramatically reducing cycle time. Perfect for high-volume orders.

Intelligent CNC Control

Our software-driven interface ensures accuracy, repeatability, and easy programming—even for complex hole patterns.

Rugged Build Quality

DUOMI CNC uses top-grade castings and precision components to guarantee long-lasting durability under heavy workloads.

Flexible Applications

From square tubes to aluminum sheets, from steel plates to stainless components—our machines handle diverse materials effortlessly.

Energy Efficiency

With optimized spindle motors, you save on electricity without sacrificing speed or torque.

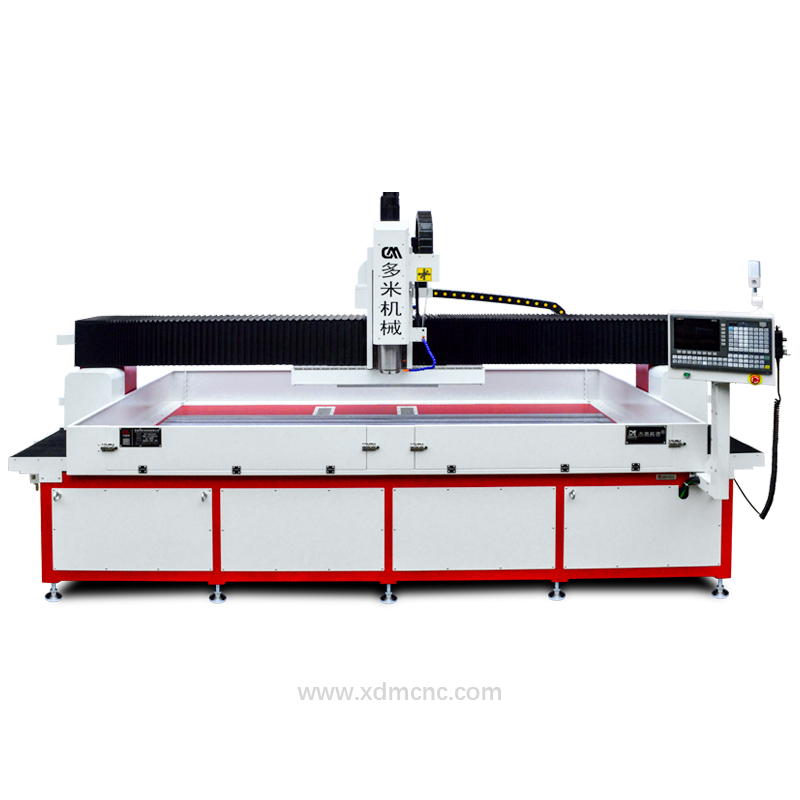

DUOMI CNC Gantry Double Spindle Drilling & Tapping for Stainless Steel

How DUOMI CNC Stands Apart

Many suppliers offer CNC equipment, but few deliver the complete package. With DUOMI CNC, you get:

Global Shipping – Machines ship quickly from China's major ports, including Shanghai, Shenzhen, Qingdao, and Guangzhou. We can also deliver from a port of your choice based on customer request.

Fast Lead Time – We pride ourselves on quick delivery schedules that keep your production on track.

Worry-Free Warranty – Every double spindle drilling and tapping machine is backed by DUOMI CNC's comprehensive warranty and lifetime support.

Proven Experience – Our machines are already trusted in workshops worldwide.

Real-World Benefits for Your Business

Let's put numbers to the story. Switching to a double spindle drilling and tapping machine can deliver:

Up to 50% faster production compared to single spindle setups

30% reduction in labor costs by minimizing manual adjustments

Zero scrap losses thanks to CNC-controlled precision

Faster return on investment – payback within months, not years

Imagine how much smoother your production would run when bottlenecks disappear.

Long-Tail Applications of Double Spindle Technology

The beauty of a double spindle drilling and tapping machine is its versatility. Some common long-tail use cases include:

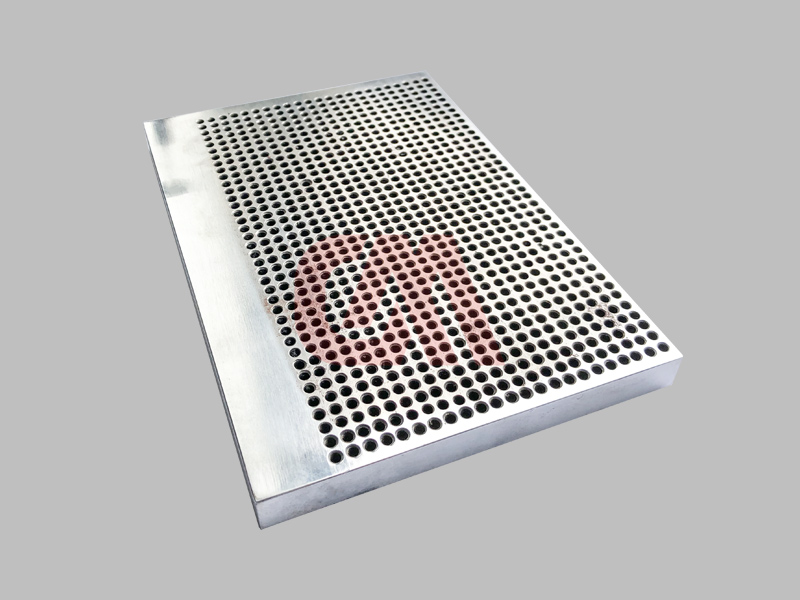

CNC drilling and tapping for aluminum profiles in furniture production

High-speed tapping in steel automotive brackets

Precision drilling in aerospace-grade titanium and alloys

Simultaneous hole and thread machining for fitness equipment tubing

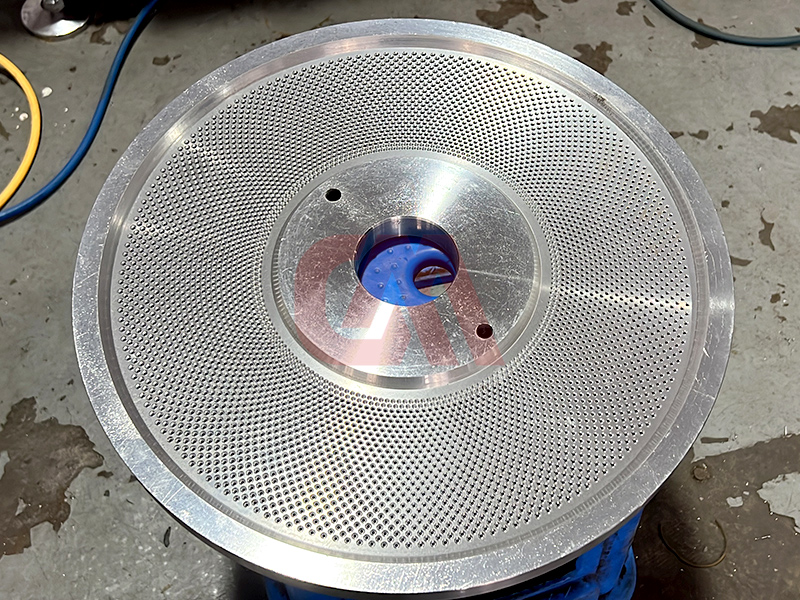

Dense filtration hole drilling in aluminum sheet metal for industrial applications

By targeting these long-tail applications, you maximize machine utilization and profits.

Why DUOMI CNC is the Partner You Need

Choosing a supplier isn't just about the machine; it's about the relationship. DUOMI CNC goes beyond manufacturing to provide:

24/7 customer service with real engineers

Video training and remote technical support

Customizable configurations to match your exact production needs

Competitive pricing without compromising on quality

We don't just sell machines—we build long-term partnerships.

Ready to Upgrade?

If you've been struggling with outdated equipment and want to double your efficiency, a DUOMI CNC double spindle drilling and tapping machine is the solution.

No more wasted labor. No more production delays. No more inconsistent quality.

Instead, you'll have:

Dual-spindle precision

Faster throughput

Worry-free operation

Global shipping to your doorstep

Final Thoughts

In a market where efficiency equals survival, sticking with old methods is a gamble you can't afford. The double spindle drilling and tapping machine from DUOMI CNC transforms your shop into a productivity powerhouse. With fast delivery from Shanghai, Shenzhen, Qingdao, Guangzhou—or any port you specify—plus a no-hassle warranty, you'll have peace of mind from day one.

So why wait? Upgrade your production line with DUOMI CNC today and experience efficiency, precision, and reliability like never before.