When it comes to drilling and punching molds in the metalworking industry, accuracy, speed, and durability are non-negotiable. Traditional manual drilling and outdated machines often leave businesses frustrated with poor hole quality, misalignment, slow production, and high labor costs. That's where the CNC Punching Mold Drilling Machine from DUOMI CNC sets a new standard.

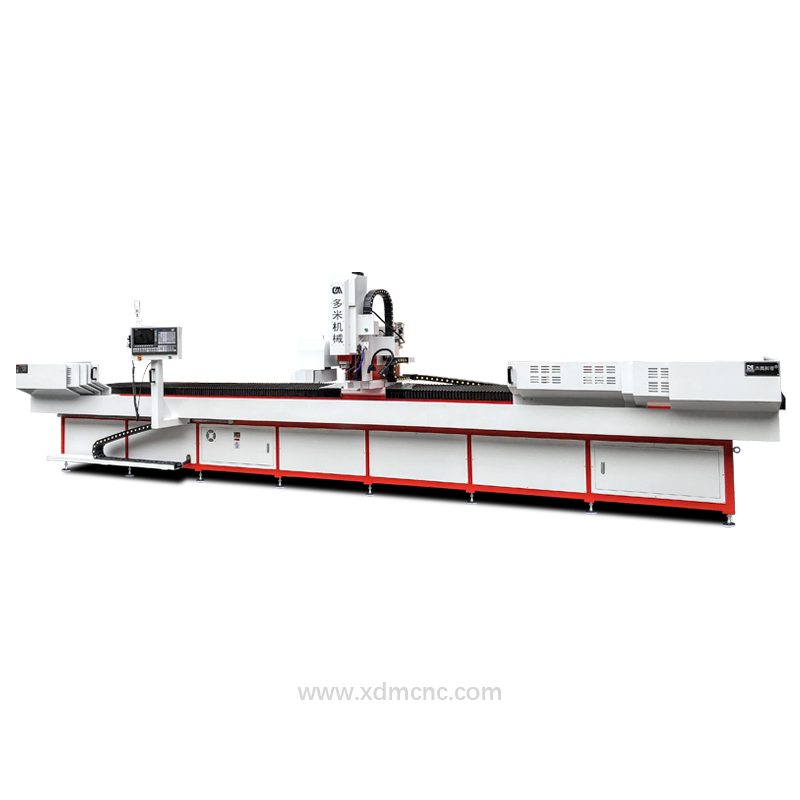

CNC Punching Mold Drilling Machine DNC-27100N10

This isn't just another machine—it's a reliable production partner built to transform your mold manufacturing process, whether you're working with steel, aluminum, copper, or other challenging metals.

Why Choose a CNC Punching Mold Drilling Machine?

Mold drilling is one of the most demanding tasks in metal fabrication. The complexity of molds, tight tolerances, and need for repeatability make traditional methods inefficient. Manual drilling often means:

Inconsistent hole depth and alignment

High scrap rates and wasted materials

Skilled labor dependency

Excessive setup times

A CNC Punching Mold Drilling Machine eliminates these problems with computer-controlled precision, automatic operation, and customized flexibility. DUOMI CNC machines deliver the power and reliability mold manufacturers need, while reducing human error and cutting down costs.

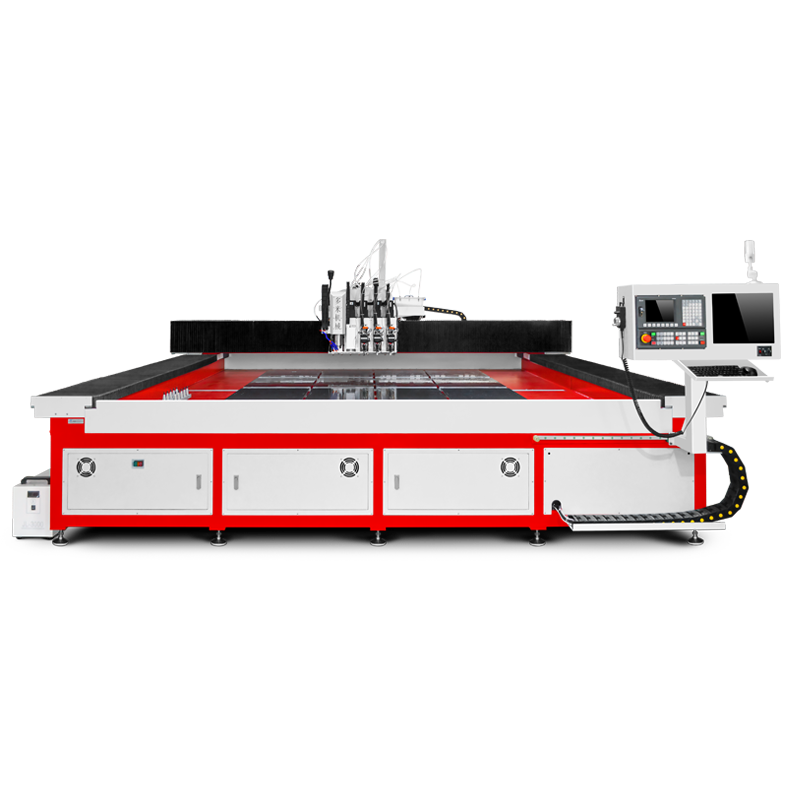

CNC Punching Mold Drilling Machine by duomi

CNC Punching Mold Drilling Machine Benefits

Extreme Precision for Complex Mold Designs

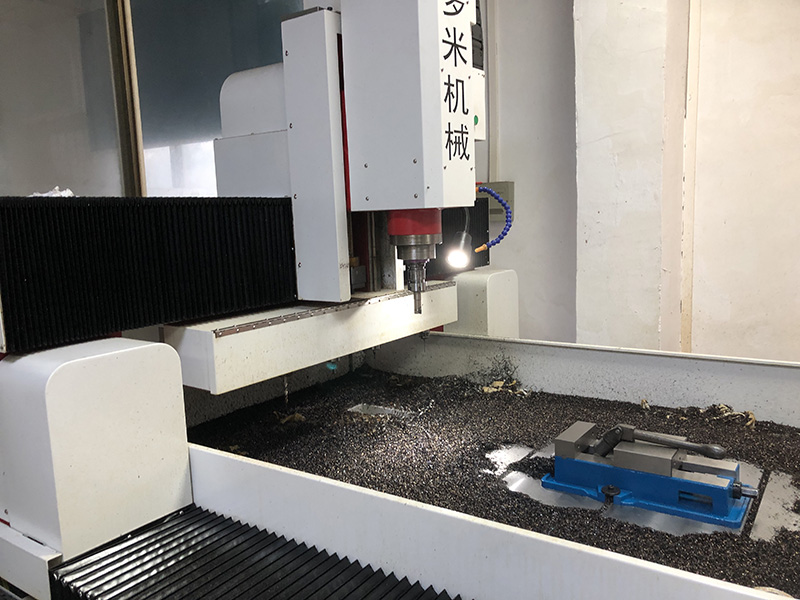

Molds require drilling thousands of holes with micrometer-level accuracy. DUOMI's CNC Punching Mold Drilling Machine achieves precision up to 0.01mm, ensuring flawless results every time, even on micro or deep holes.

Faster Production, Less Downtime

With spindle speeds reaching 60,000 RPM, our machines drastically reduce cycle times compared to manual drilling or outdated equipment. Multiple holes can be drilled in sequence without repositioning, which means faster delivery for your clients.

Compatible with Various Metals

From hardened steel to lightweight aluminum and copper alloys, DUOMI CNC machines adapt easily. No matter the mold material, drilling remains stable, accurate, and efficient.

Lower Labor Costs & Easy Operation

Traditional drilling requires skilled operators. With DUOMI's CNC Punching Mold Drilling Machine, operators can be trained in just days. No programming background needed—simple controls mean anyone can achieve professional results.

CNC Punching Mold Drilling Machine vs. Traditional Methods

Let's break down the pain points of traditional drilling and how DUOMI CNC machines solve them:

Manual drilling requires constant adjustment → CNC offers automated precision.

Inconsistent hole spacing → CNC guarantees exact repeatability.

Slow production rates → CNC machines process multiple holes in minutes.

High dependency on skilled labor → CNC simplifies operation for all levels.

Expensive mistakes and rework → CNC reduces scrap rates and improves ROI.

In short, while old methods hold you back, CNC technology pushes your business forward.

Why DUOMI CNC Punching Mold Drilling Machine Stands Out

Choosing the right supplier matters just as much as choosing the right machine. With DUOMI CNC, you don't just buy a machine—you invest in long-term reliability.

Customized Machine Design

Every mold-making project is unique. DUOMI CNC provides fully customizable solutions, from machine bed sizes to drilling ranges, ensuring your machine fits your exact needs.

Unmatched Durability

Built with industrial-grade steel frames and high-precision guide rails, our machines are engineered for continuous operation, even under heavy workloads.

Global Shipping from Major Chinese Ports

We ship worldwide from Shanghai, Shenzhen, Qingdao, and Guangzhou. Customers can also specify their preferred port, ensuring fast and cost-effective delivery.

Fast Lead Time & Hassle-Free Warranty

DUOMI CNC guarantees rapid production and shipment, so you don't have to wait months for your equipment. Plus, every machine comes with a worry-free warranty and 24/7 global service support.

Applications of CNC Punching Mold Drilling Machine

Our machines are trusted across multiple industries, including:

Automotive molds – precision drilling for engine and chassis components.

Aerospace molds – lightweight but durable drilling for complex parts.

Electronics molds – micro-hole drilling for high-tech components.

Plastic injection molds – perfect for consistent pin holes and vent holes.

Metal casting molds – robust drilling for high-strength applications.

Wherever mold drilling is required, DUOMI CNC machines deliver results.

Customer Success Stories

One of our clients in Germany, a mold manufacturer for automotive parts, reported 40% faster production and 30% lower defect rates after switching to the DUOMI CNC Punching Mold Drilling Machine.

Another customer in the United States, specializing in electronic molds, was able to expand production capacity without hiring additional skilled operators, thanks to our easy-to-use CNC interface.

Ready to Upgrade Your Mold Drilling Process?

The future of mold manufacturing belongs to automation and precision. Traditional drilling methods will only slow you down and eat into profits. By investing in a CNC Punching Mold Drilling Machine from DUOMI CNC, you'll enjoy:

Faster production cycles

Higher precision and reliability

Lower labor and material costs

Global shipping from major Chinese ports (Shanghai, Shenzhen, Qingdao, Guangzhou)

Fast lead times and worry-free warranty support

Don't let outdated machines hold back your business. Contact DUOMI CNC today and discover how our CNC Punching Mold Drilling Machine can take your production to the next level.