DUOMI CNC Drilling Machines for Long Metal Profiles: Redefining Precision and Productivity

In today's industrial world, efficiency and accuracy are the cornerstones of manufacturing excellence. Whether you are working in structural steel fabrication, rail construction, or heavy machinery manufacturing, the ability to drill long metal profiles with precision is vital.

That's where the CNC drilling machine for long metal profiles from DUOMI CNC (DUOMICNC) comes in — engineered to deliver unmatched accuracy, high speed, and reliability for metal processing industries across the globe.

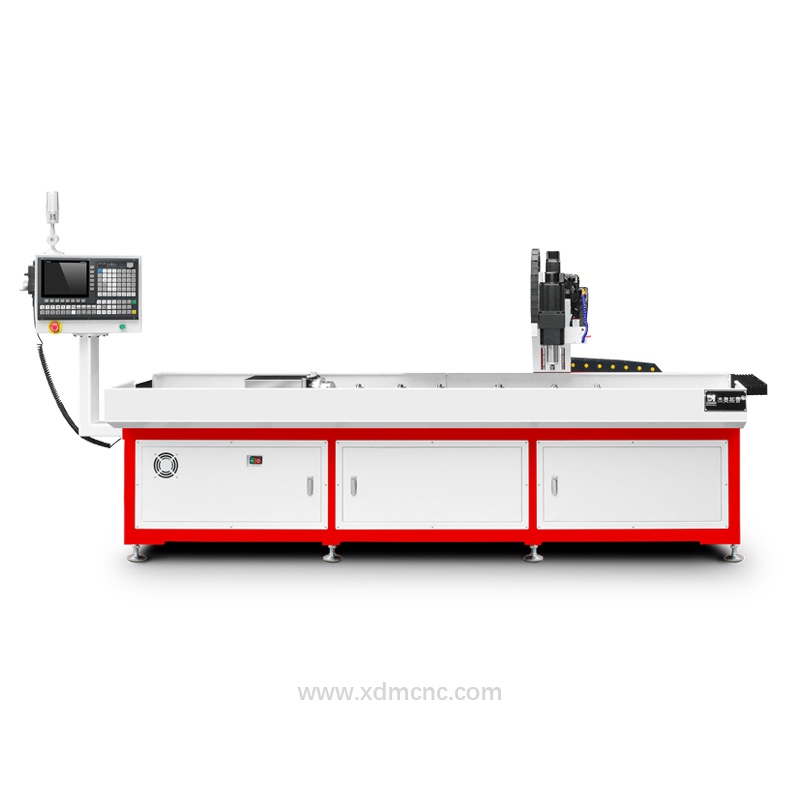

Customer’s production workshop using the DUOMI CNC long metal profile drilling machine

What Is a Long Metal Profile Drilling Machine?

A long metal profile drilling machine is a type of metal drilling machine specifically designed to process long, heavy, or large-sized metal components — such as beams, channels, rails, pipes, and plates.

Unlike conventional drill presses that handle small workpieces, these CNC systems are built for extended materials that can reach several meters in length.

With automated tool paths, servo-driven feed systems, and intelligent positioning, DUOMI CNC machines provide perfectly aligned and repeatable drilling results, regardless of profile length or thickness.

Why Long Metal Profiles Require Special Drilling Solutions?

Drilling on long profiles such as H-beams, square tubes, or large aluminum extrusions presents unique challenges:

Maintaining accuracy over long distances

Preventing vibration and tool deflection

Ensuring stable clamping and alignment

Handling heavy or flexible materials efficiently

Traditional drilling machines often fail to deliver consistent quality under these demanding conditions. That's why DUOMICNC developed a full range of CNC drilling machines for long metal profiles, engineered specifically for stability, precision, and industrial-scale productivity.

DUOMI CNC: Precision Meets Power

DUOMI CNC has been manufacturing advanced metal drilling machines for over a decade, serving industries such as construction, aerospace, shipbuilding, automotive, and energy.

Every DUOMI CNC drilling system is designed with customizable length, travel range, and automation options, allowing manufacturers to meet their specific production requirements.

Whether your workpiece is 1 meter or 13 meters long, DUOMI CNC can build a system that ensures accuracy, efficiency, and long-term reliability.

Key Features of DUOMI CNC Drilling Machines for Long Metal Profiles

1. Extra-Long Machining Travel

DUOMICNC machines can be custom-built with travel lengths ranging from 400mm up to 13,000mm or more. This flexibility allows manufacturers to handle both short and ultra-long metal profiles without repositioning or manual adjustment.

2. Intelligent CNC Control

Powered by a high-performance CNC system, operators can easily program hole positions, patterns, and depths. The control panel is intuitive and designed for non-programmer use, allowing quick learning and seamless operation.

3. High-Speed and High-Precision Spindle

Each DUOMI CNC drilling machine is equipped with a servo-driven high-speed spindle capable of drilling various metals — from aluminum and brass to stainless steel and hardened alloys — with precision up to ±0.01mm.

4. Rigid Structure for Long Profiles

The machine base and frame are made from heavy-duty cast iron and welded steel, ensuring zero deformation under load. The rigid structure keeps long materials stable during high-speed drilling, reducing vibration and improving hole quality.

5. Automatic Clamping and Positioning

Advanced hydraulic or pneumatic clamps securely hold the metal profile in place, while an auto-alignment system ensures every hole is drilled at the correct coordinate — even for complex or angled profiles.

6. Multi-Spindle Options

For high-volume production, DUOMI CNC offers multi-spindle long profile drilling machines, capable of drilling multiple holes simultaneously, greatly improving throughput.

Applications of Long Metal Profile Drilling Machines

DUOMI CNC machines are used in a wide range of industries that demand precision, durability, and adaptability.

1. Structural Steel and Construction

In steel fabrication and construction, beams, columns, and support frames require precise drilling for bolted connections. DUOMICNC's long metal profile drilling machines ensure accurate hole placement, improving assembly efficiency and structural integrity.

2. Aerospace and Rail Industry

For aerospace components and railway structures, even the slightest dimensional error can cause performance issues. DUOMI CNC machines guarantee consistency and precision in drilling lightweight metal profiles like aluminum and titanium.

3. Shipbuilding and Offshore Engineering

Large ship frames and marine components often involve massive steel profiles. The robust structure of DUOMI CNC drilling machines ensures deep-hole drilling capability without compromising accuracy — even in harsh industrial environments.

4. Automotive Manufacturing

From chassis frames to suspension systems, the automotive industry relies on precision drilling for durability and performance. DUOMI CNC machines handle both small and long metal parts with speed and accuracy.

5. Energy and Heavy Equipment

For wind turbine components, power plants, or oilfield structures, DUOMICNC's CNC drilling machine for long metal profiles can process thick steel and alloy materials with consistent quality, meeting global engineering standards.

Technical Specification

Max Drilling Length: Up to 13,000 mm (customizable)

Hole Diameter Range: 0.03 mm – 30 mm

Precision: ±0.01 mm

Spindle Speed: Up to 12,000 RPM

Axis Configuration: 3-Axis / 4-Axis Custom

Material Capability: Steel, Aluminum, Copper, Brass, Titanium

Cooling System: oil or Liquid Cooling

Automation Options: Auto Tool Change, Auto Loading/Unloading

Software Interface: Touchscreen CNC Control System

Benefits of Using a DUOMICNC Long Metal Profile Drilling Machine

1. One Setup, Full-Length Machining

No need for repositioning or manual alignment — the machine handles the entire profile in one cycle, improving speed and reducing errors.

2. Perfect Accuracy for Every Hole

Thanks to high-precision motion control and laser alignment systems, each hole maintains consistent diameter and depth across long distances.

3. High Productivity and Reduced Labor

Fully automated drilling operations save time, reduce manpower, and ensure repeatable quality for every batch.

4. Strong Durability and Low Maintenance

All components — from spindle bearings to motion rails — are built with industrial-grade materials, ensuring long service life and minimal maintenance downtime.

5. Custom Solutions for Every Industry

DUOMI CNC provides complete customization, from machine size to spindle configuration, so every customer gets a machine perfectly suited to their product and process.

Customer Success Story

A European manufacturer of aluminum rail systems faced bottlenecks using traditional drilling machines. The long profiles (over 6 meters) required multiple manual repositionings, causing time loss and accuracy deviations.

After installing a DUOMICNC CNC drilling machine for long metal profiles, production efficiency improved by over 50%, and positional accuracy reached ±0.01 mm.

The system's automatic clamping, servo control, and digital interface allowed one operator to manage multiple drilling cycles — greatly reducing labor costs.

DUOMI CNC: Global Expertise, Local Support

With clients in over 40 countries, DUOMI CNC has become a trusted name in precision drilling technology. Each machine is built with:

European-standard precision

Japanese motion control systems

Chinese manufacturing efficiency

DUOMICNC offers global after-sales service, including:

On-site installation and training

Remote troubleshooting

Spare parts support

Lifetime technical assistance

This ensures customers can operate their machines confidently and continuously without production delays.

Future-Ready Manufacturing with DUOMI CNC

As industries embrace smart manufacturing and Industry 4.0, DUOMI CNC is leading innovation in connected, intelligent drilling solutions.

Next-generation DUOMI CNC long profile drilling machines feature:

IoT-enabled monitoring systems

Real-time data analytics for predictive maintenance

AI-driven drilling optimization algorithms

Energy-efficient design to reduce operating costs

By integrating technology with precision mechanics, DUOMI CNC is not only improving production — it's transforming how manufacturers think about drilling.

Conclusion: The Perfect Choice for Long Metal Profile Drilling

The demand for precision, speed, and flexibility in metal fabrication continues to grow. To stay ahead, manufacturers need equipment that can handle large-scale, high-accuracy drilling without compromise.

A CNC drilling machine for long metal profiles from DUOMI CNC delivers exactly that — a balance of engineering excellence, operational simplicity, and cutting-edge technology.

From custom design to global service, DUOMICNC ensures every client achieves maximum productivity, flawless accuracy, and unmatched reliability.

Contact DUOMI CNC Today

For more details on metal drilling machines and CNC solutions for long metal profiles, contact us today:

Website: www.xdmcnc.com

Email: [email protected]

WhatsApp/Phone: +852 6915 4799

DUOMI CNC — Precision That Drives Innovation.