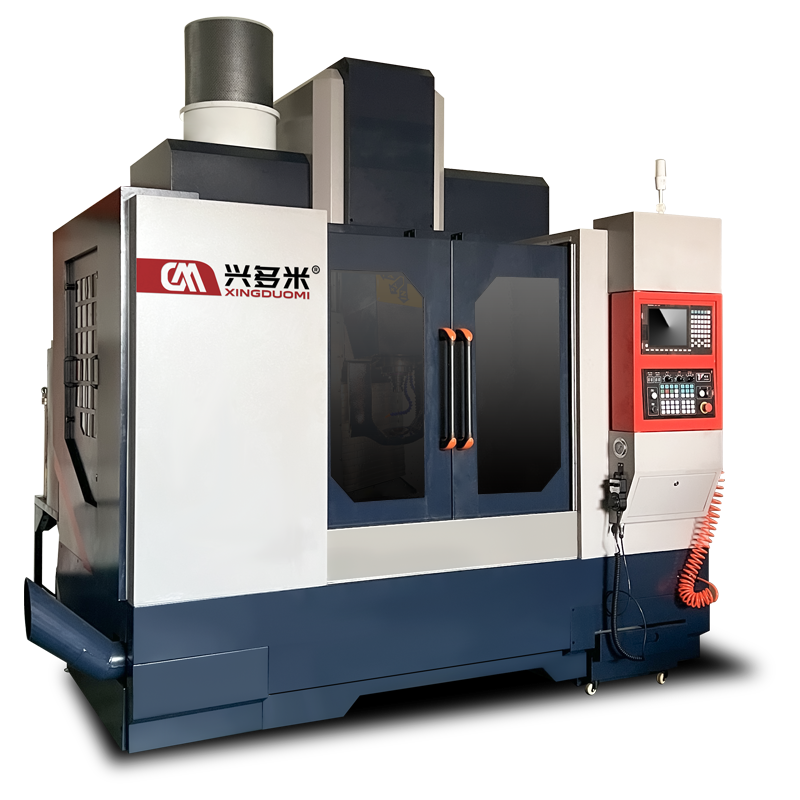

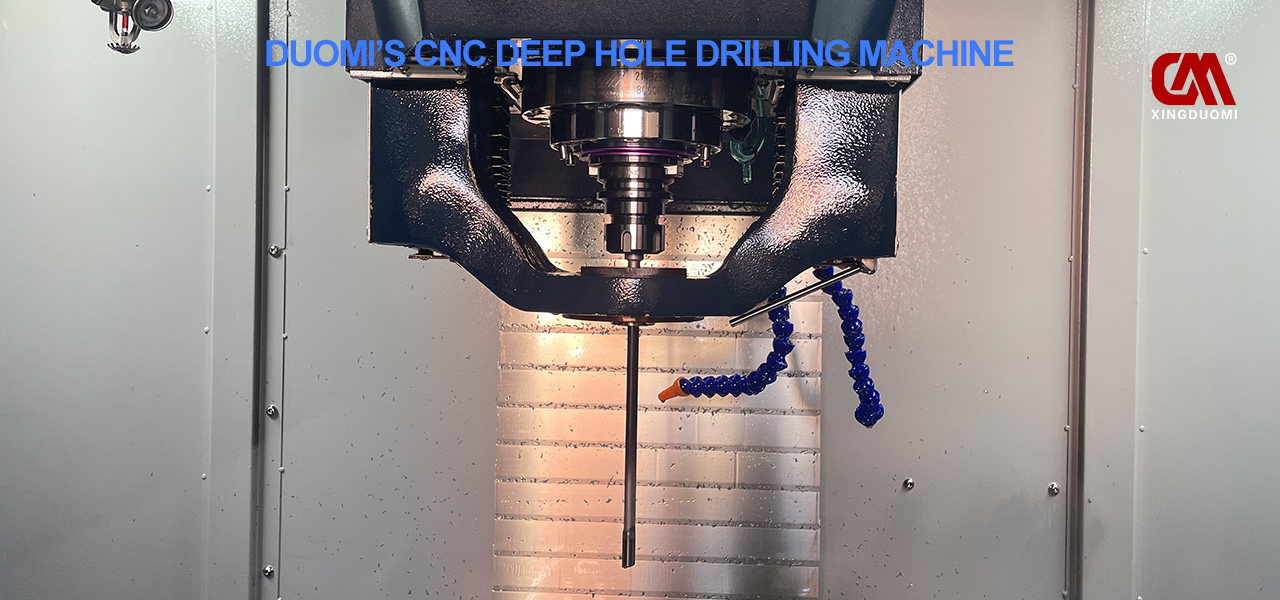

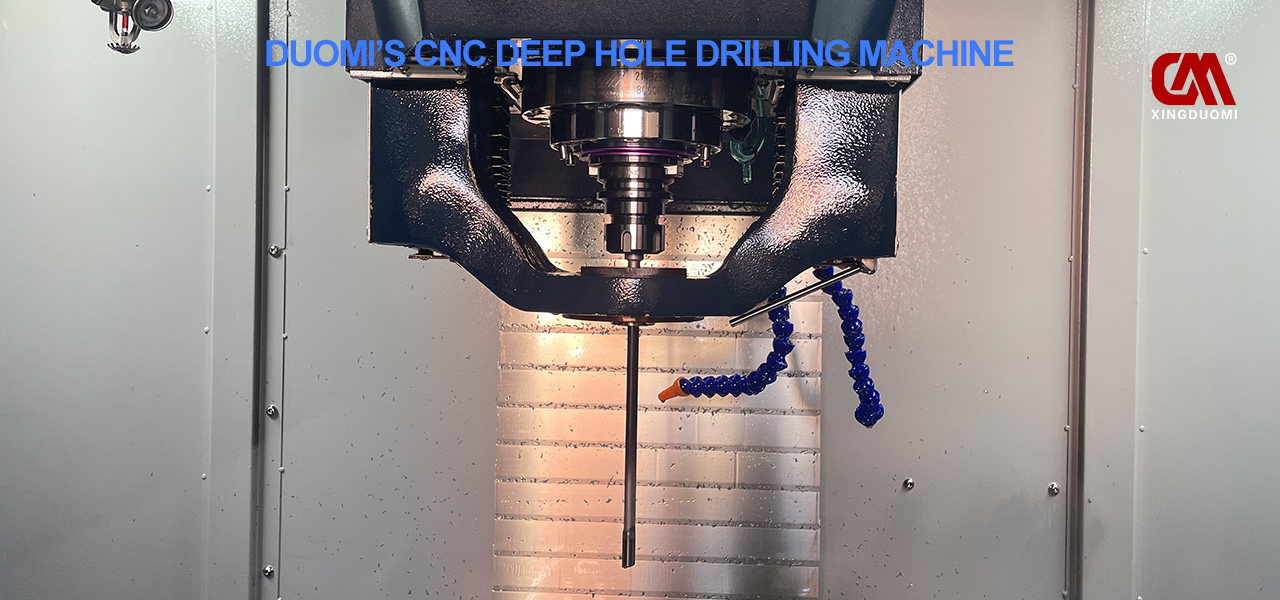

DUOMI'S CNC DEEP HOLE DRILLING MACHINE

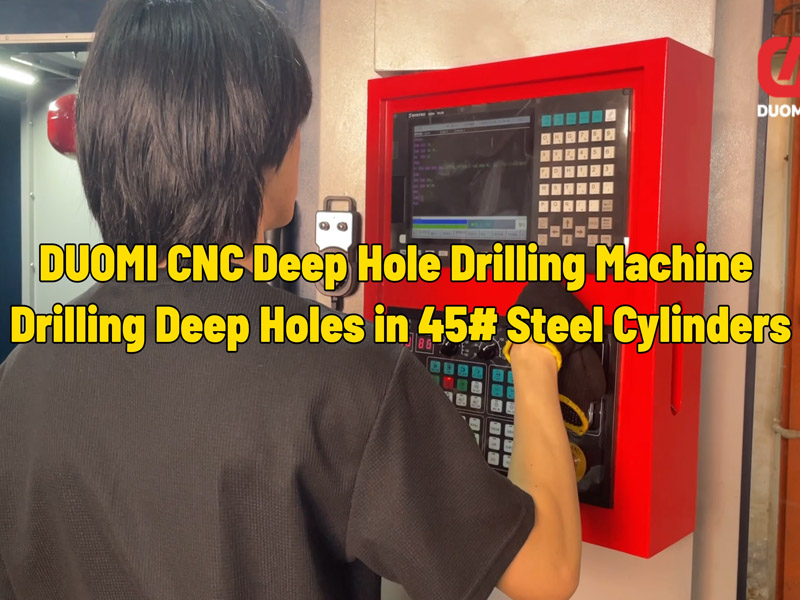

Intelligent CNC Control, Easy Operation

The machine is powered by a Taiwan SYNTEC CNC control system, allowing one-touch machining and intuitive operation. Even complex deep hole drilling CNC processes can be executed smoothly with minimal training, reducing setup time and operator dependency.

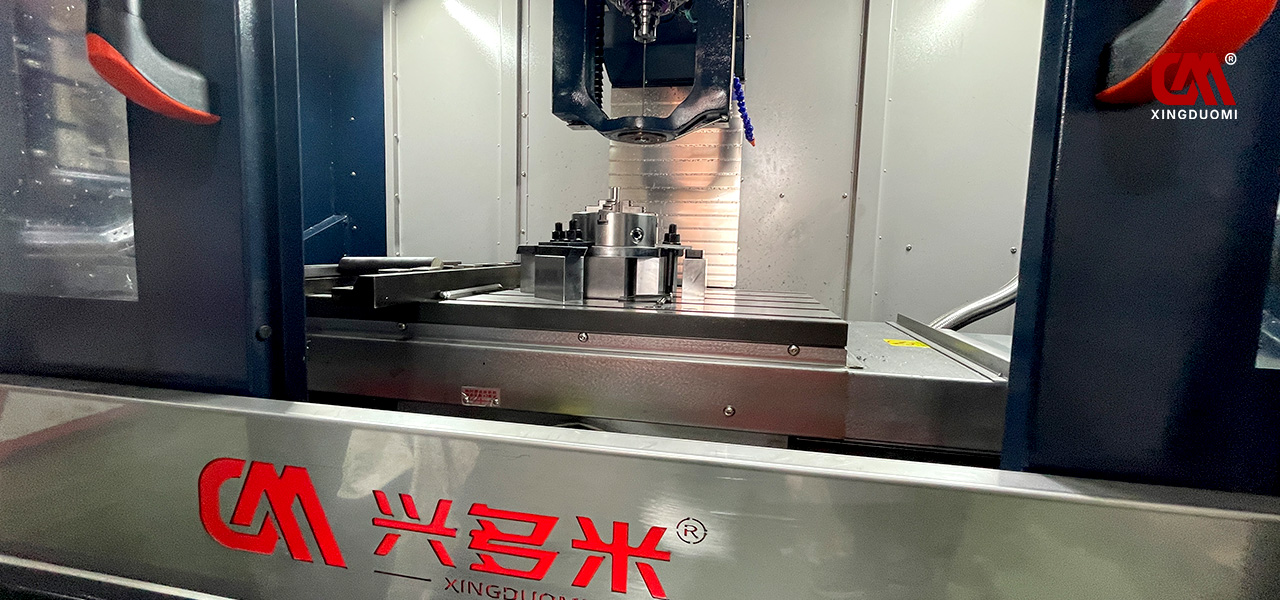

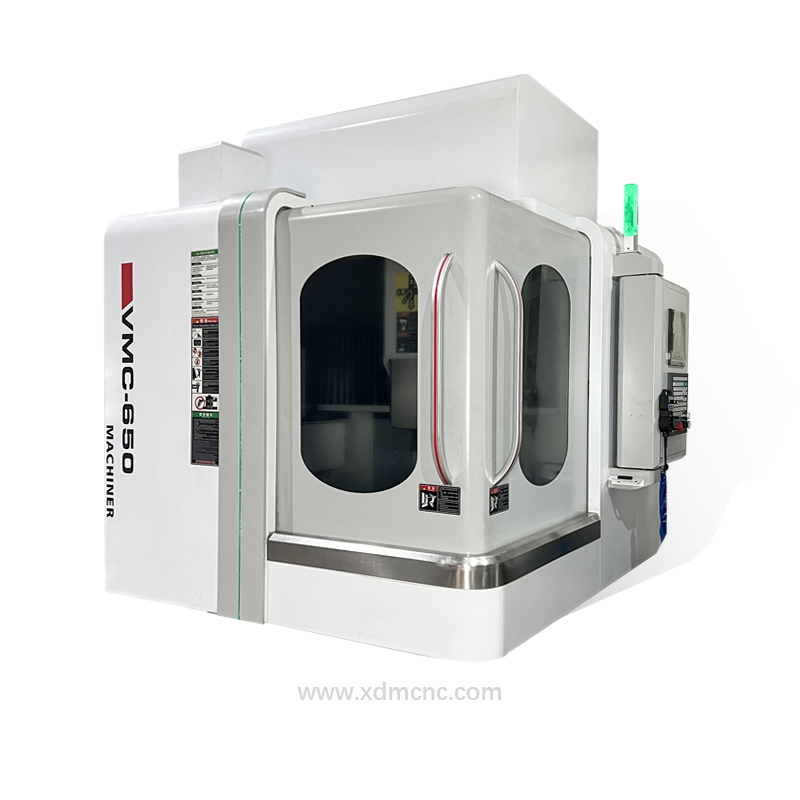

Rigid Structure for Deep Drilling Applications

An extra-wide base combined with a herringbone-style column forms a one-piece cast structure. This design significantly improves rigidity and vibration resistance, which is critical for deep drilling machine operations involving small diameters and long depths.

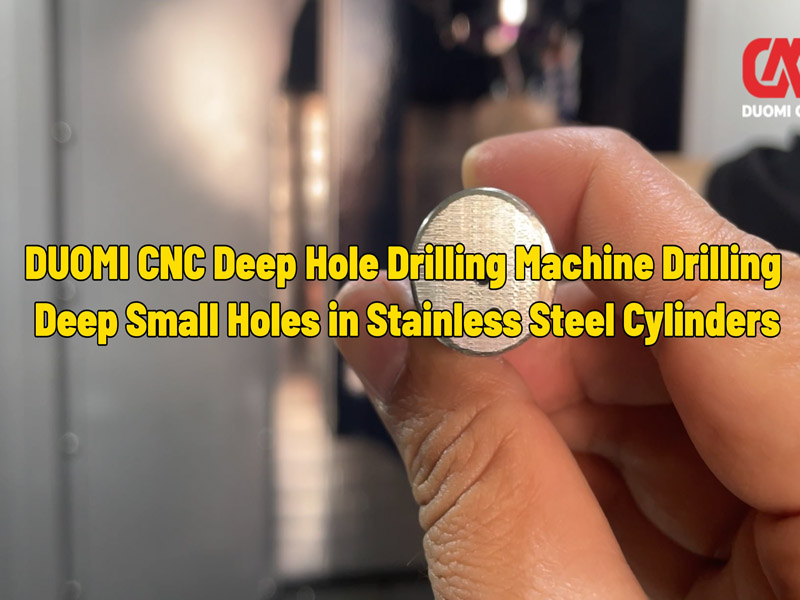

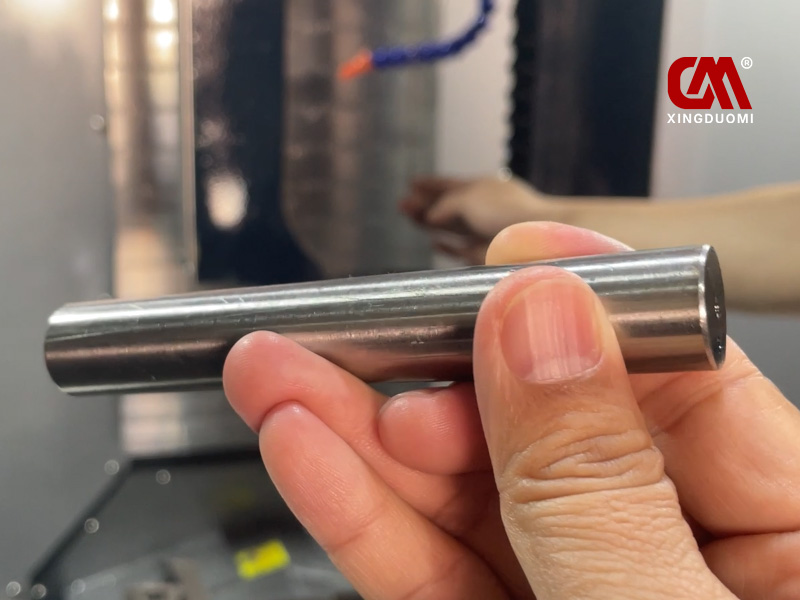

High-Precision Spindle Performance

The spindle adopts a Taiwan DANNCHUAN servo mechanical spindle, delivering stable torque and precise rotation. Drilling accuracy remains consistent, with surface finish reaching Ra 0.8 or better, even in demanding small diameter deep hole drilling applications.

Full Servo Drive for Stable Motion

All axes are driven by servo motors, ensuring precise positioning, smooth movement, and long-term operational stability. This configuration is especially important for cnc deep hole drilling machine processes where alignment and repeatability directly affect hole quality.

Premium Linear Motion Components

Each axis uses Taiwan-imported HIWIN / TBI high-precision linear guideways and ball screws. These components offer high rigidity, low noise, and reliable accuracy, supporting both deep hole drilling and boring machine applications.

Clean and Safe Working Environment

An integrated oil mist collection system helps maintain a clean workshop environment while improving operator safety. Fully enclosed machine guarding further protects both personnel and equipment during continuous operation.

Built-In Protection for Daily Production

The machine is equipped with X / Y / Z axis travel limit protection, effectively preventing damage caused by incorrect operation. This feature adds another layer of security in real production environments.

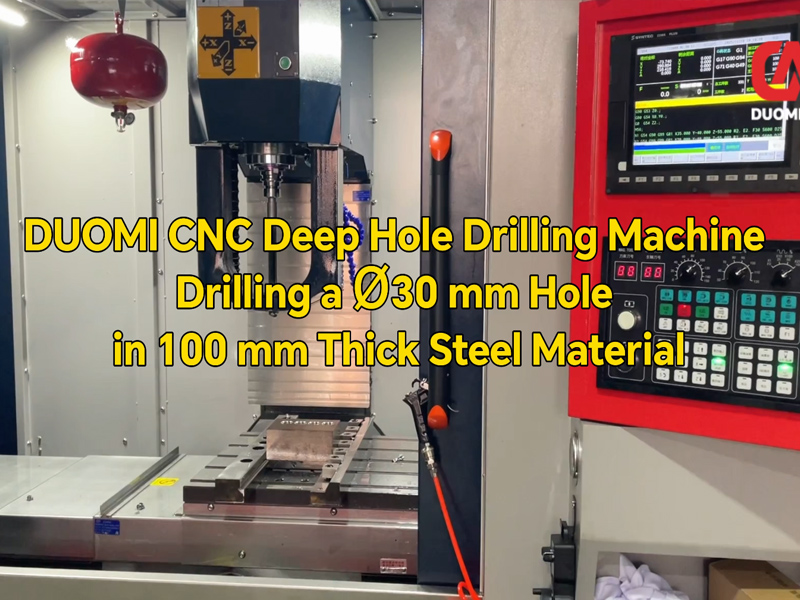

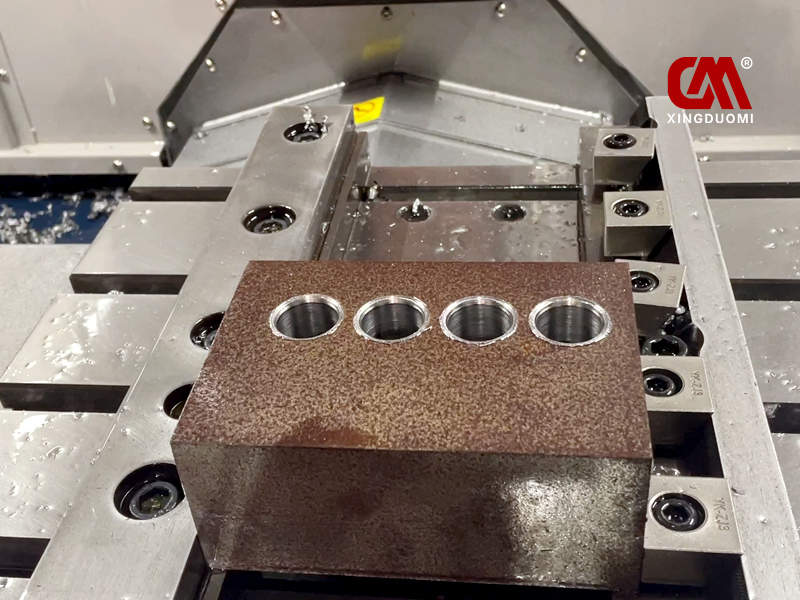

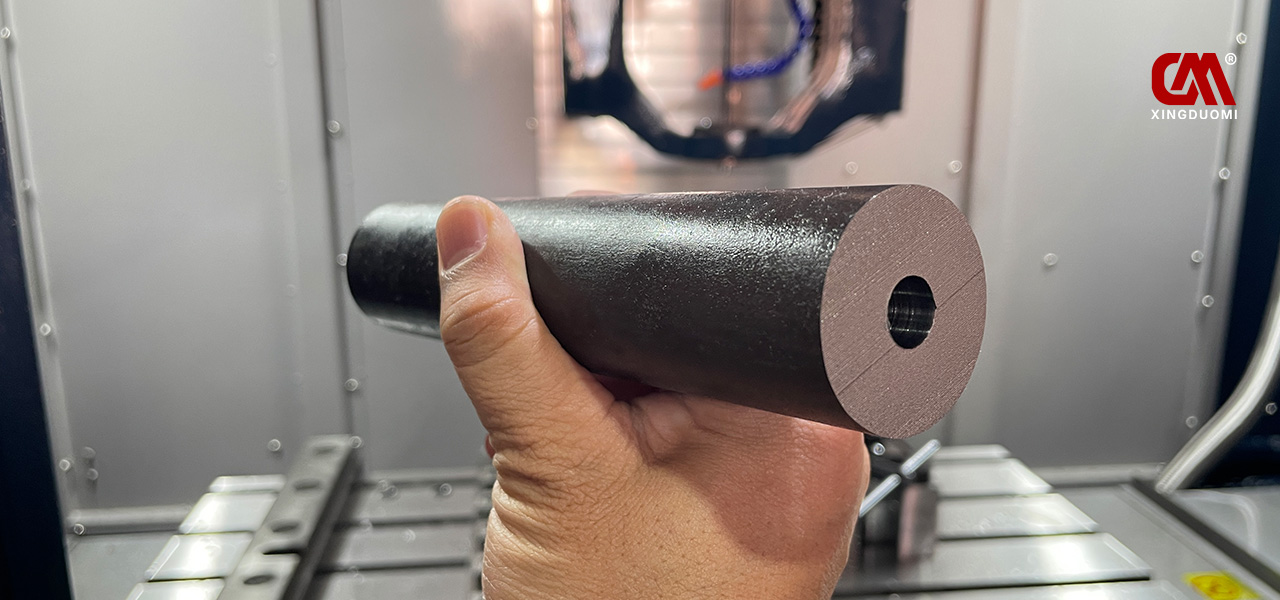

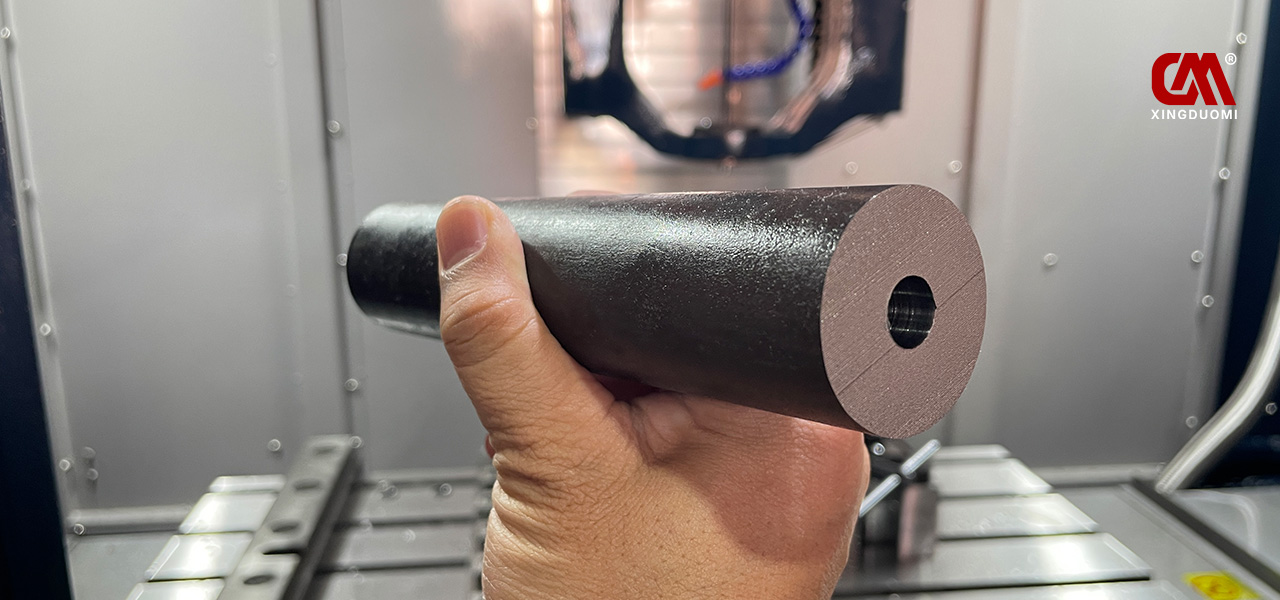

CNC Deep Hole Drilling Machine for 45#SS Deep Hole Drilling

Verified Accuracy Before Delivery

Every machine is inspected and calibrated using an American-imported API laser measurement system. Positioning errors are measured and compensated before shipment, ensuring the machine performs as expected from day one.

Automatic Lubrication for Long Service Life

An automatic lubrication system is installed on all axes to ensure consistent lubrication of transmission components. This reduces wear, extends machine life, and minimizes maintenance effort for operators.

A CNC Deep Hole Drilling Machine You Can Rely On

Whether you refer to it as a deep hole drill machine, deep drilling machine, or deep hole drilling CNC, the requirement remains the same: accuracy, stability, and reliability over time.

DUOMI CNC builds machines for real manufacturing conditions—where performance must remain consistent, shift after shift.

Talk to DUOMI CNC

If you are looking for a dependable cnc deep hole drilling machine tailored to your material, hole size, and production volume, our engineering team is ready to assist.

DUOMI CNC

Precision drilling solutions, built for industry.

Request A Quote

Request A Quote