Unparalleled CNC Drilling Technology – Built to Boost Your Production Efficiency

In today's fiercely competitive manufacturing landscape, efficiency, precision, and speed are the cornerstones of success. Whether you're in the automotive, furniture, fitness equipment, or industrial hardware sector, the demand for high-performance drilling solutions has never been higher. At DUOMI CNC, we deliver cutting-edge CNC drilling machines engineered to revolutionize your production line and drive operational excellence.

Why CNC Drilling Machines Are Crucial in Modern Manufacturing

CNC (Computer Numerical Control) drilling technology is transforming how manufacturers process metals, tube sheets, and structural profiles. With digital control systems, manufacturers gain unmatched precision, consistency, and repeatability — crucial for industries relying on high-output and flawless quality.

Whether you're working with stainless steel, aluminum, or carbon steel, a high-speed CNC drilling machine ensures cleaner holes, faster cycle times, and minimal material waste.

The DUOMI Advantage: Precision, Power, and Productivity

DUOMI's CNC drilling machines are not just tools — they're productivity partners. Designed for multi-spindle, horizontal, and tube sheet drilling, our equipment integrates seamlessly into modern assembly lines, reducing manual intervention and optimizing throughput.

Key Features:

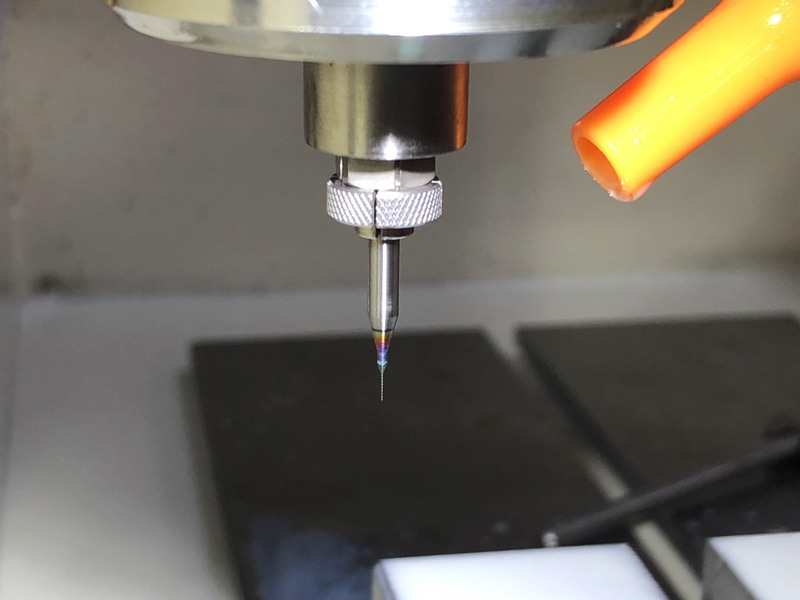

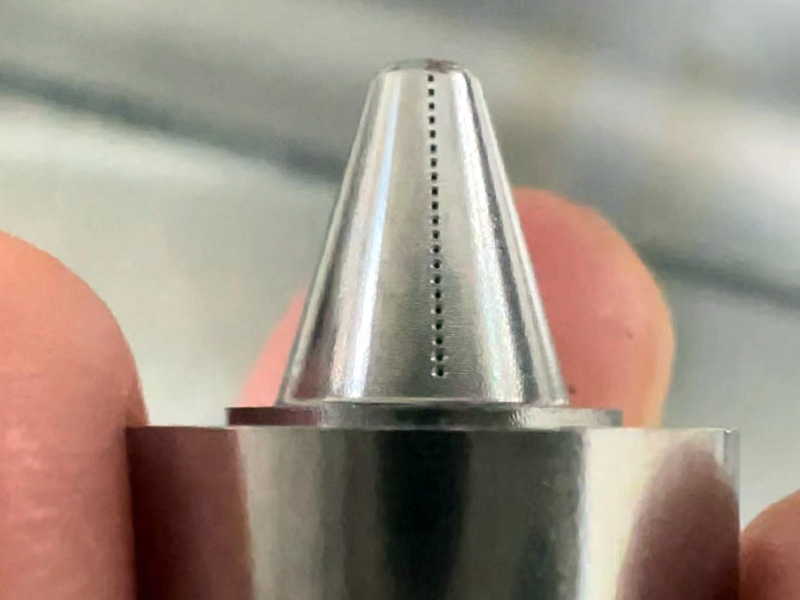

Drilling hole diameters as small as 0.03mm, with unmatched accuracy.

Multi-spindle configurations for simultaneous operations.

High-speed spindles to meet the demands of fast-paced production.

Heavy-duty frames and reinforced Z-axis slides for stability and long-term precision.

Customizable drilling heads for specific material types and thicknesses.

Applications Across Industries

Our CNC drilling solutions are widely adopted in:

Furniture manufacturing: Ideal for rectangular tube frame structures.

Display rack production: Precision drilling of square or round pipes.

Fitness equipment fabrication: Structural integrity requires exact hole alignment.

Automotive and EV components: High-volume, high-precision drilling is essential.

Tube sheet and plate drilling: For HVAC, petrochemical, and water treatment industries.

No matter your niche, our solutions adapt to your workflow and scale with your growth.

How CNC Drilling Boosts Production Efficiency

Efficiency isn't just about speed — it's about smart output. With automated tool paths, reduced setup times, and less human error, CNC drilling machines dramatically lower production costs. Additionally, integrated cooling systems and chip removal features reduce downtime and wear, ensuring longer machine life and higher ROI.

Benefits You'll Notice:

Faster production cycles

Consistent quality with tight tolerances

Lower labor costs

Improved workplace safety

Increased output capacity

Global Reach with Local Support

As a leading CNC drilling machine manufacturer, DUOMI serves clients worldwide. We offer global shipping, local installation support, and 24/7 technical assistance to ensure your production never stops.

Click on the image for more details

Whether you're in the United States, Southeast Asia, Europe, or the Middle East, we're ready to bring world-class drilling solutions to your doorstep.

Ready to Upgrade Your Drilling Technology?

If you're looking to gain a competitive edge, boost productivity, and reduce waste, it's time to invest in unparalleled CNC drilling technology from DUOMI.